TBD604-L6 marine diesel engine for demanding propulsion and power generation

The TBD604-L6 is a proven six‑cylinder workhorse engineered for heavy‑duty operation in marine and stationary environments. While it belongs to the 604 DIESEL series designed by MWM & Deutz, the focus here is the TBD604-L6 itself: a robust inline configuration that delivers dependable torque, consistent fuel efficiency, and long service intervals under continuous load. Shipowners, operators, and procurement teams value the TBD604-L6 for its straightforward mechanics, durable materials, and predictable lifecycle costs in real‑world service.

As a 4‑stroke, turbocharged and charge‑air‑cooled platform, the TBD604-L6 balances power density with longevity. Typical duty ratings cover continuous propulsion and generator‑drive tasks, from harbor craft and coastal vessels to offshore support equipment and industrial plants. Its design philosophy emphasizes stable performance over thousands of operating hours, supported by accessible maintenance points and comprehensive documentation.

TBD604-L6 technical characteristics and performance data

The TBD604-L6 configuration is an inline six (L6) with a cast‑iron block and wet‑liner cylinders for serviceable longevity. It uses pressure‑charged induction with charge‑air cooling to sustain high mean effective pressure at conservative thermal loads. Mechanical fuel injection—with application‑tuned pump and injector setups—supports reliable combustion across a broad operating envelope.

Depending on duty and calibration, a typical TBD604-L6 marine engine delivers output in the mid‑hundreds of kilowatts, commonly in the approximate 400–900 kW range. Speed ranges are application‑specific, with continuous ratings often set between about 900 and 1,800 rpm to match propeller laws or generator frequencies (50/60 Hz). The engine sits in the double‑digit‑liters displacement class, prioritizing high torque at low and mid speeds for efficient propulsion and steady generator loads. Cooling and lubrication systems are dimensioned for continuous service: jacket‑water cooling with heat‑exchanger or keel‑cooling options, high‑capacity oil pump and full‑flow filtration, and instrumentation to safeguard operation.

Why it is widely adopted: the TBD604-L6 combines straightforward, field‑proven design with parts commonality across the 604 DIESEL family. For operators seeking a dependable MWM & Deutz solution, the TBD604-L6 diesel engine offers predictable fuel consumption, strong load acceptance, and resilient behavior under variable sea states or cyclic industrial loads.

- · Inline 6‑cylinder, 4‑stroke, turbocharged and charge‑air‑cooled.

- · Approx. 400–900 kW depending on duty rating and setup.

- · Broad speed range around 900–1,800 rpm for propulsion and gensets.

- · High torque at low speed for efficient propeller drive.

- · Mechanical fuel system for robust, easy‑to‑service operation.

- · Designed for marine and stationary roles with long TBO.

- · Strengthened block, wet liners, and service‑friendly layout.

- · Supported by TBD604-L6 OEM parts and global know‑how.

TBD604-L6 marine engine applications in shipping and stationary use

The TBD604-L6 is frequently specified for primary or auxiliary propulsion on coastal cargo vessels, passenger ferries, patrol and workboats, dredgers, and offshore support vessels. In propulsion, the engine’s low‑speed torque enables economical steaming and good maneuverability, while the steady thermal balance supports longevity in heavy seas. As a generator‑drive unit, the TBD604-L6 integrates seamlessly into shipboard power systems, emergency gensets, and land‑based power modules for ports or industrial facilities. Operators also deploy the TBD604-L6 to drive pumps, compressors, and hydraulic systems where continuous duty and fast load pick‑up are essential. In each case, the engine’s mechanical simplicity and well‑documented maintenance procedures reduce lifecycle risk and ease planning for scheduled overhauls.

For purchasers comparing options, the TBD604-L6 MWM & Deutz marine engine stands out by aligning proven metallurgy and conservative component stress with the performance needed to meet modern operational profiles. Its footprint and service access promote fast turnarounds, while established supply chains simplify parts planning. Whether configured for propulsion or power generation, the TBD604-L6 diesel engine remains a pragmatic choice where uptime and predictable OPEX matter most.

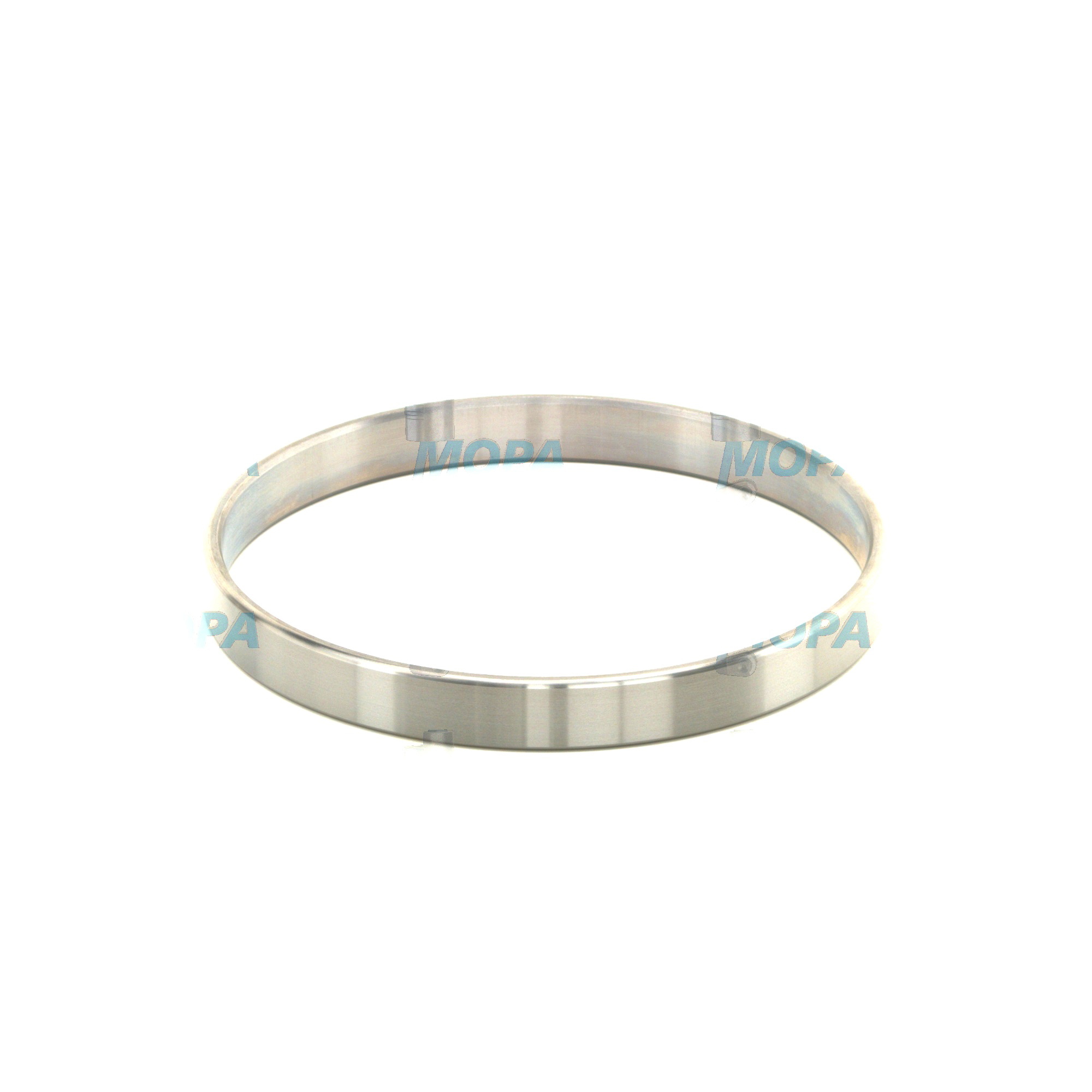

OEM spare parts suitable for TBD604-L6: performance, reliability, and service life

Using OEM spare parts suitable for TBD604-L6 is essential to keep performance, reliability, and service life on target. Precision‑matched components—liners, pistons and rings, bearings, fuel‑injection elements, turbocharger cartridges, valves, and gaskets—are manufactured to the dimensions, tolerances, surface finishes, and material specs the engine was designed around. That compatibility maintains combustion quality, oil control, and thermal stability across long running periods, helping the TBD604-L6 hold its fuel economy, emissions consistency, and power output between overhauls.

Beyond fit and material integrity, calibration consistency matters. Fuel‑system elements built to the intended flow curves and opening pressures preserve injection timing and spray patterns, which is critical to load acceptance and cylinder‑to‑cylinder balance. Likewise, correctly matched cooling and lubrication components protect against hot spots and film breakdown under continuous duty. The cumulative effect is less unplanned downtime, fewer repeat repairs, and sustained availability for vessels and plants.

MOPA is a reliable partner for OEM spare parts suitable for TBD604-L6. With deep product knowledge and access to specification‑compliant components, MOPA supports purchasing teams with proper identification, documentation, and timely supply. If you are standardizing on the TBD604-L6 OEM parts portfolio, MOPA helps reduce procurement complexity and supports cohesive maintenance planning across fleets and facilities.

Why choose OEM spare parts suitable for TBD604-L6

OEM spare parts suitable for TBD604-L6 protect asset value by maintaining engineered clearances, coatings, and heat‑treatment profiles that generic components frequently miss. They also support stable condition‑monitoring trends—making wear‑particle analysis, vibration readings, and exhaust temperature mapping more meaningful—because the engine behaves as designed after each service event. For operators managing tight schedules and regulatory scrutiny, that predictability is a key operational advantage.

Conclusion: the TBD604-L6 advantage and assured parts availability

The TBD604-L6 combines a rugged inline‑six architecture with the balanced performance required for propulsion and generator duties, making it a dependable choice for shipowners and industrial operators. Its proven design from the 604 DIESEL lineage delivers efficient torque, straightforward maintenance, and strong availability.

To sustain this performance over the long term, source OEM spare parts suitable for TBD604-L6 through MOPA. With expert support and specification‑compliant components, MOPA helps keep your TBD604-L6 operating at its intended level throughout its service life.