TBG604-BV16 gas engine for high-efficiency power and CHP

The TBG604-BV16 is a proven 16‑cylinder V-configuration gas engine built for dependable output and long running hours. As part of the 604 GAS lineage from MWM & Deutz, it leverages decades of large-engine experience, yet the spotlight firmly remains on the strengths of the TBG604-BV16 itself: robust mechanical design, solid electrical efficiency in continuous duty, and excellent suitability for combined heat and power (CHP) as well as prime and standby generation.

Engine room operators, plant owners, and maritime decision-makers value the TBG604-BV16 for its balance of fuel economy and lifecycle performance. In many installations it drives gensets at 1,500 rpm for 50 Hz grids or 1,800 rpm for 60 Hz, enabling straightforward integration into utility-parallel or island-mode sites. With a lean-burn combustion system, turbocharging, and efficient charge-air cooling, the platform delivers reliable power density while meeting demanding emissions targets when configured accordingly.

TBG604-BV16 technical characteristics and performance

The TBG604-BV16 is a 16‑cylinder, V‑type, turbocharged and intercooled gas engine designed for continuous-duty operation on natural gas and, when configured, other methane-based fuels. Typical rated outputs are in the multi‑megawatt class, commonly around the 2.5–3.2 MW electrical range at 50 Hz and comparable outputs for 60 Hz packages, depending on specific configuration, gas quality, and emissions settings. The lean-burn concept increases efficiency and reduces NOx, while electronic ignition and cylinder‑selective knock control stabilize performance under varying fuel qualities and ambient conditions.

Core design features include a stiff crankcase for low vibration, optimized combustion chambers for high detonation resistance, and durable valve train and piston–liner combinations tailored for long service intervals. In CHP applications, the TBG604-BV16 can deliver high total system efficiency—electrical efficiency complemented by substantial recoverable heat from jacket water and exhaust gas, allowing overall efficiencies frequently above 85% with a well‑engineered heat recovery system.

Where deployed as a marine engine in onboard genset duty, the TBG604-BV16 offers steady hotel-load coverage and auxiliary power with markedly lower particulate emissions than a comparable diesel engine, making it attractive for ferries, cruise support systems, and offshore accommodation vessels that prioritize clean operation and fuel cost control.

- · 16‑cylinder V configuration for compact high output

- · Lean-burn combustion for efficiency and low NOx

- · Turbocharged and charge‑air cooled for power density

- · Typical 1,500/1,800 rpm for 50/60 Hz grids

- · Multi‑MW electrical class; well‑suited to CHP

- · Electronic ignition and knock monitoring

- · Stable baseload and excellent part‑load behavior

- · Broad fuel tolerance within specified methane number

Applications of the TBG604-BV16 in power and marine

In stationary generation, the TBG604-BV16 is widely used by municipal utilities, industrial plants, data centers, and district heating operators that demand predictable output and high availability. Its strong CHP performance fits greenhouses, food and beverage processing, hospitals, and campus energy systems where thermal recovery drastically lowers total energy cost. For islanded or microgrid sites, the engine’s governor response and load acceptance are well matched to modern power management systems.

In maritime contexts, the TBG604-BV16 serves as an auxiliary or prime mover for onboard power plants—supporting cargo vessels, passenger ships, and offshore vessels seeking cleaner operation relative to traditional diesel engine solutions. Its stable frequency control and fuel efficiency make it a compelling TBG604-BV16 marine engine option for electric propulsion support or hotel services, especially where access to pipeline or LNG‑derived gas is feasible.

Why operators value the TBG604-BV16 by MWM & Deutz

Operators favor the TBG604-BV16 for its lifecycle economics: strong electrical efficiency, long maintenance intervals when operated within specification, and predictable parts consumption. The engine’s mature design eases installation and commissioning, while its control architecture integrates well with modern plant SCADA and marine automation systems. Compared with a conventional diesel engine of similar output, users often cite lower fuel cost per kWh (where gas pricing is favorable) and the ability to meet stringent air-quality requirements with lean-burn calibration and appropriate exhaust treatment.

For fleet managers running mixed assets, the TBG604-BV16 simplifies standardization: consistent core components across the 604 GAS family, a broad service network, and well-documented maintenance procedures. This supports uptime targets in both grid‑parallel plants and marine auxiliary power stations.

TBG604-BV16 OEM parts and service: the value of OEM spare parts suitable for TBG604-BV16

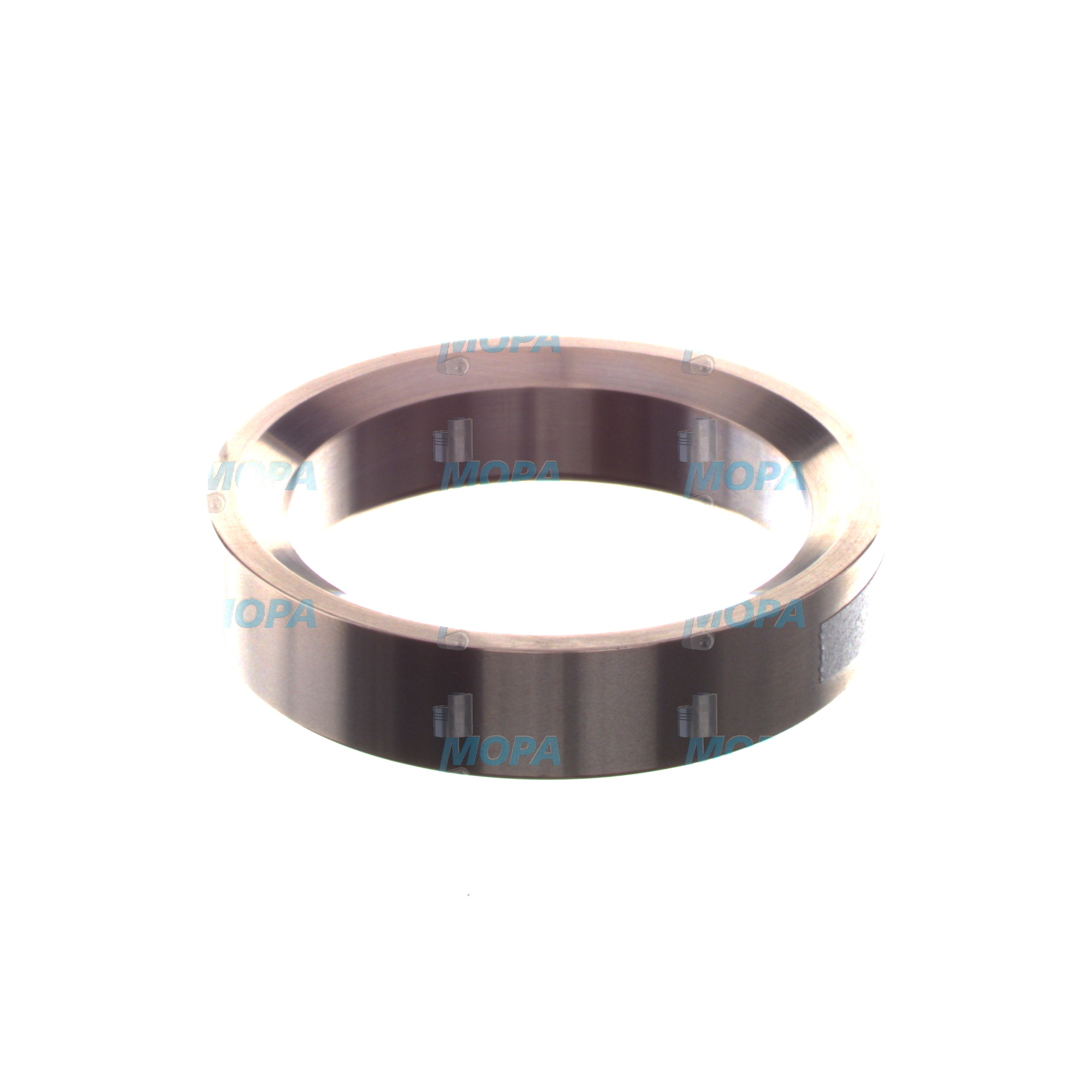

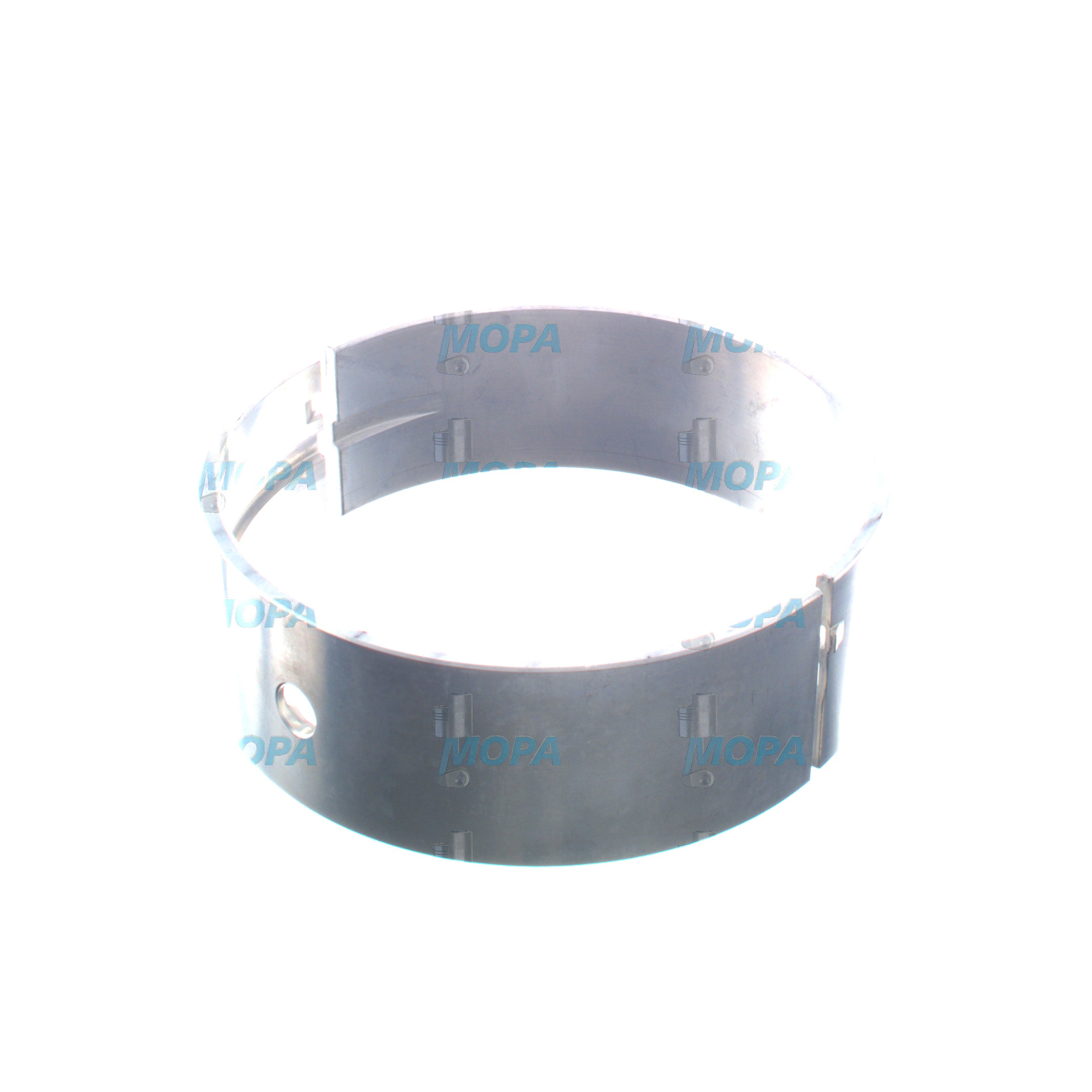

Performance, reliability, and service life depend on the quality and compatibility of every component that enters the engine. Using OEM spare parts suitable for TBG604-BV16 maintains the precise tolerances, materials, and calibrations the engine was designed around—critical for ignition components, pistons and liners, turbochargers, gas mixers, regulators, sensors, and control electronics. Correct combustion geometry and verified materials help sustain efficiency, protect against detonation, and keep emissions within the expected band.

By specifying OEM spare parts suitable for TBG604-BV16, operators preserve key performance indicators over time: electrical output, heat recovery yields in CHP mode, oil consumption, and intervals between overhauls. Consistent component quality supports predictable maintenance planning, reduces the likelihood of unplanned outages, and safeguards major assemblies like crankshafts and cylinder heads from secondary damage.

MOPA is a reliable partner for OEM spare parts suitable for TBG604-BV16. From fast supply of TBG604-BV16 OEM parts to technical cross‑checks against engine serials and build lists, MOPA helps ensure the right component arrives on time and fits first time. Coordinated deliveries, documentation, and expert support streamline overhauls and scheduled inspections, whether your TBG604-BV16 runs as a CHP prime mover or as a TBG604-BV16 marine engine genset.

- · Protects efficiency and emissions stability

- · Preserves clearances and critical tolerances

- · Supports long service intervals and uptime

- · Reduces risk of knock, misfire, and thermal stress

- · Ensures seamless integration with controls

- · Backed by MOPA logistics and technical support

Conclusion: TBG604-BV16 performance with assured parts supply

The TBG604-BV16 combines proven MWM & Deutz engineering with modern lean‑burn efficiency, making it a dependable choice for power plants, CHP installations, and onboard gensets where stable, economical output is essential. To sustain that performance over the long term, count on OEM spare parts suitable for TBG604-BV16 supplied by MOPA—your reliable partner for availability, precision, and consistent engine results.