TBD616-V12 marine engine insights and parts

The TBD616-V12 is a proven V-configuration 12-cylinder powerhouse built for dependable, heavy-duty performance in maritime and stationary roles. While it belongs to the 616 DIESEL series developed by MWM & Deutz, the emphasis here is squarely on the engine type TBD616-V12 itself: a medium-speed, turbocharged and charge-air cooled diesel engine valued for its balance of power density, fuel efficiency, and robust mechanical design. For shipowners and technical buyers, the TBD616-V12 offers the combination of reliable propulsion or auxiliary power with lifecycle economics that stand the test of demanding operations.

TBD616-V12 marine engine: technical overview and performance characteristics

The TBD616-V12 diesel engine is designed for long service intervals and consistent output under continuous load. Its core architecture features 12 cylinders in a compact V layout, optimized for smooth running and favorable power-to-weight ratios. Typical configurations employ turbocharging with charge-air cooling, four-stroke combustion, and mechanical fuel injection governed by a precise speed control system. In marine propulsion or auxiliary genset configurations, the engine is tailored through rating selections that match vessel or plant duty profiles.

Typical speed ranges for the TBD616-V12 sit in the medium-speed segment (approximately 1,000–1,800 rpm), enabling efficient coupling to marine gearboxes or generators. Continuous propulsion and auxiliary ratings are commonly specified in the 1–2 MW class (roughly 1,000–2,000 kW), subject to charge-air setup and rating definitions for continuous, prime, or standby duty. Within the broader MWM & Deutz 616 DIESEL platform, the bore and stroke architecture yields per‑cylinder swept volumes in the multi‑liter range, placing the total displacement of the TBD616-V12 firmly in the multi‑tens‑of‑liters class appropriate for medium-speed marine engines. Fuel system layouts and charge-air configurations vary by build list to balance emissions, fuel consumption, and response characteristics.

Why is the TBD616-V12 particularly valued? Operators prize its mechanical simplicity relative to its output, solid thermal management, and parts commonality across the 616 DIESEL series family. The engine’s design supports high uptime through durable cylinder heads, replaceable wet liners, and rugged crankshaft and bearing arrangements engineered for sustained load. Additionally, the TBD616-V12 marine engine integrates well with standard marine auxiliaries—coolers, pumps, filtration, and monitoring—streamlining installation on newbuilds and retrofits.

- · 12-cylinder V-configuration; four-stroke, turbocharged, charge-air cooled.

- · Medium-speed operation around 1,000–1,800 rpm for propulsion and genset duty.

- · Continuous output typically in the 1–2 MW class, rating-dependent.

- · Robust cylinder design with wet liners for serviceability and longevity.

- · Strong parts commonality across the 616 DIESEL platform.

- · Optimized for marine engine reliability and fuel efficiency.

Applications of the TBD616-V12 diesel engine in shipping and stationary service

The TBD616-V12 excels as both a propulsion prime mover and as an auxiliary or emergency generator drive. In shipping, it is widely deployed where dependable torque and consistent fuel economy are critical over long operating hours. Common maritime uses include:

Cargo, passenger, and offshore vessels

In cargo vessels and bulk carriers, the TBD616-V12 marine engine provides steady propulsion or drives high-capacity gensets for onboard systems. Passenger ships and ferries favor the engine type for its smooth running characteristics and predictable load acceptance—vital for hotel loads and maneuvering. Offshore supply vessels benefit from the engine’s rugged build, supporting DP systems and heavy auxiliary loads with stable frequency control when configured as a generator set. In all these roles, the TBD616-V12 by MWM & Deutz is appreciated for lifecycle reliability and straightforward maintenance routines.

Power generation and industrial applications

Beyond shipping, the TBD616-V12 diesel engine serves as a reliable driver for stationary power plants, peak shaving units, and critical standby systems. Its medium-speed ratings pair efficiently with generators for continuous or prime power, while the engine’s cooling and lubrication systems are adaptable to varied ambient conditions and duty cycles. Industrial operators value the combination of high mechanical efficiency and durable component design that supports long operational periods between planned overhauls.

Benefits of OEM spare parts suitable for TBD616-V12

Reliable performance from a TBD616-V12 is closely tied to the quality and compatibility of replacement components used in inspections, service intervals, and overhauls. OEM spare parts suitable for TBD616-V12 are engineered to the same dimensional tolerances, materials, and performance criteria as the engine’s reference specifications. This precise fit and function helps preserve combustion quality, oil control, and thermal behavior—key factors for maintaining efficiency and extending service life.

Using OEM spare parts suitable for TBD616-V12 also supports consistent rating compliance. Correct injector characteristics, turbocharger components, charge-air coolers, pistons, liners, bearings, and valve-train parts keep the engine aligned with its intended power curve and emissions profile. Over time, this alignment reduces the risk of unplanned downtime and helps stabilize total cost of ownership by minimizing repeat interventions and peripheral damage from mismatched components.

- · Precise fit preserves compression, injection timing, and sealing integrity.

- · Consistent materials and heat treatment support long overhaul intervals.

- · Stable output and fuel economy across propulsion and genset ratings.

- · Reduced risk of secondary wear from dimensional mismatch.

- · Clear traceability and documentation for fleet maintenance records.

MOPA is a reliable partner for OEM spare parts suitable for TBD616-V12. With application knowledge covering propulsion and auxiliary configurations, MOPA supports purchasers and technical teams with component selection, documentation, and timely delivery. Whether you operate a TBD616-V12 marine engine on a cargo vessel, a passenger ferry, an offshore vessel, or in a stationary plant, MOPA streamlines sourcing to keep maintenance windows short and predictable.

MOPA support for TBD616-V12 OEM parts and lifecycle management

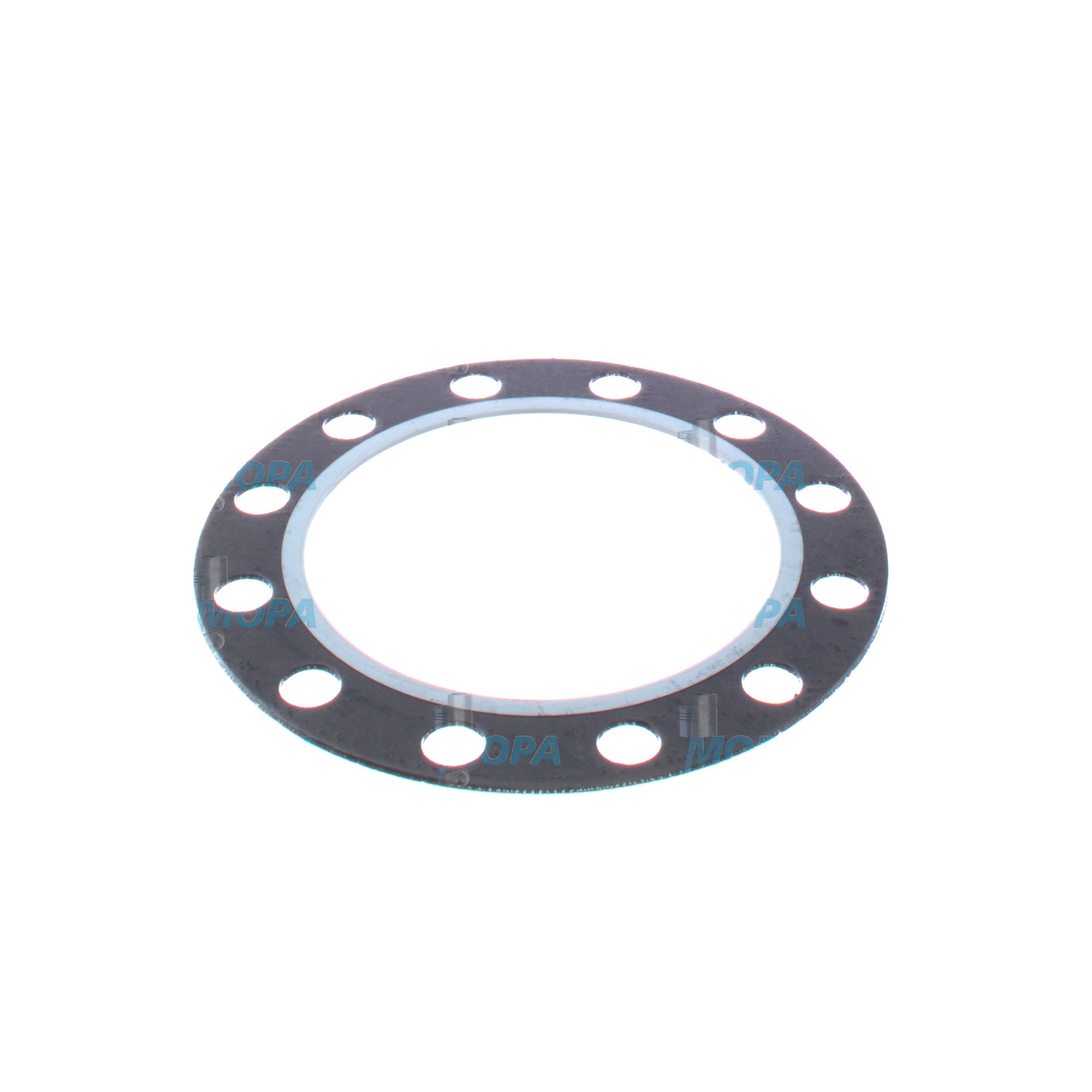

From scheduled overhauls to condition-based replacements, MOPA helps align maintenance plans with engine hours, rating class, and operational demands. The focus remains on OEM spare parts suitable for TBD616-V12—injectors, pumps, turbocharger cartridges, pistons, rings, liners, bearings, gasket sets, filters, and cooling components—delivered with technical clarity so your crew can execute work scopes efficiently and safely.

Conclusion: why the TBD616-V12 stands out

The TBD616-V12 delivers the blend of medium-speed efficiency, robust mechanics, and adaptable ratings that shipowners and plant operators require for dependable daily service. Its 12-cylinder V layout, strong thermal management, and parts commonality within the 616 DIESEL series by MWM & Deutz make it a sound choice for propulsion and power generation.

To sustain this performance over the long term, OEM spare parts suitable for TBD616-V12 are essential. MOPA supplies OEM spare parts suitable for TBD616-V12 with the technical support and responsiveness professionals expect, helping you protect uptime and total cost of ownership across the engine’s lifecycle.