TBD620-V12 marine engine for demanding operations

The TBD620-V12 is a proven medium-speed diesel engine designed for heavy-duty propulsion and power generation. While it belongs to the 620 DIESEL series by MWM & Deutz, the focus for operators is squarely on the robust V12 configuration itself: high torque across a broad speed range, compact dimensions for its output class, and excellent thermal stability under continuous load. Shipowners and plant operators value the TBD620-V12 for dependable performance, straightforward serviceability, and enduring lifecycle economics.

As a V12 four-stroke platform with turbocharging and charge-air cooling, the TBD620-V12 combines efficient combustion with high specific output. It is commonly configured for marine gas oil (MGO) or marine diesel oil (MDO), with variants tailored for diverse marine and stationary roles. For repowers and fleet standardization, the engine’s modular systems and familiar architecture help minimize integration risks while supporting predictable maintenance planning.

TBD620-V12 technical characteristics and performance

The TBD620-V12 diesel engine is a 12-cylinder, V-arranged, turbocharged and charge-air cooled design engineered for continuous and prime-duty operation. Typical continuous power ratings span roughly 1,200 to 2,700 kW depending on configuration, with nominal speed windows from about 900 to 1,500 rpm. Total displacement is around 50–55 liters, enabling strong low-end torque and steady load acceptance—key for propulsion, shaft alternators, and onboard auxiliary generation. Direct fuel injection with precisely matched injection pumps and nozzles supports efficient atomization and stable combustion, even under variable loads.

Core construction features include a rigid crankcase, replaceable wet cylinder liners, and high-capacity cooling and lubrication circuits designed for sustained thermal balance. Depending on the rating, single or twin-turbo arrangements are used alongside generously sized charge-air coolers to maintain intake density and keep exhaust temperatures within design limits. Mechanical or electronic speed governors can be found across the installed base, and both electric and air-start variants exist to suit different class and shipyard preferences.

For operators balancing fuel, maintenance, and uptime, the TBD620-V12 stands out as a workhorse. Its durable valvetrain, service-friendly cylinder head design, and well-established component ecosystem underpin long time-between-overhaul intervals when maintained to specification. In many fleets, the engine is integrated with class-approved monitoring and shutdown systems to safeguard critical parameters during harsh operating profiles.

Applications of the TBD620-V12 marine engine and genset

The TBD620-V12 is widely deployed across maritime and stationary sectors due to its power density and proven reliability. As a propulsion prime mover, it is frequently specified for ferries, offshore support vessels, tugs, patrol craft, and dredgers—vessels that need high torque at moderate shaft speeds and predictable response to maneuvering loads. In auxiliary roles, it drives marine generator sets supplying shipboard power, bow thrusters, deck machinery, and emergency systems.

Onshore, the same engine platform serves industrial power plants, mining and oil-and-gas facilities, and mission-critical standby installations. Its medium-speed operating envelope and stable voltage/frequency behavior make it a fit for continuous baseload, island-mode operation, and black-start scenarios. The balance of efficiency, robustness, and maintainability is the key reason the TBD620-V12 is widely retained during mid-life refits and modernization programs.

TBD620-V12 by MWM & Deutz within the 620 DIESEL series

Within the MWM & Deutz 620 DIESEL series, the TBD620-V12 occupies a sweet spot between footprint and output. The V12 geometry offers compact installation while preserving the service access needed for routine inspections, cylinder head changes, and injector calibrations. For fleets running mixed propulsion and auxiliary sets, the shared 620 DIESEL platform simplifies crew training, spare parts stocking, and diagnostic procedures—further reinforcing lifecycle value.

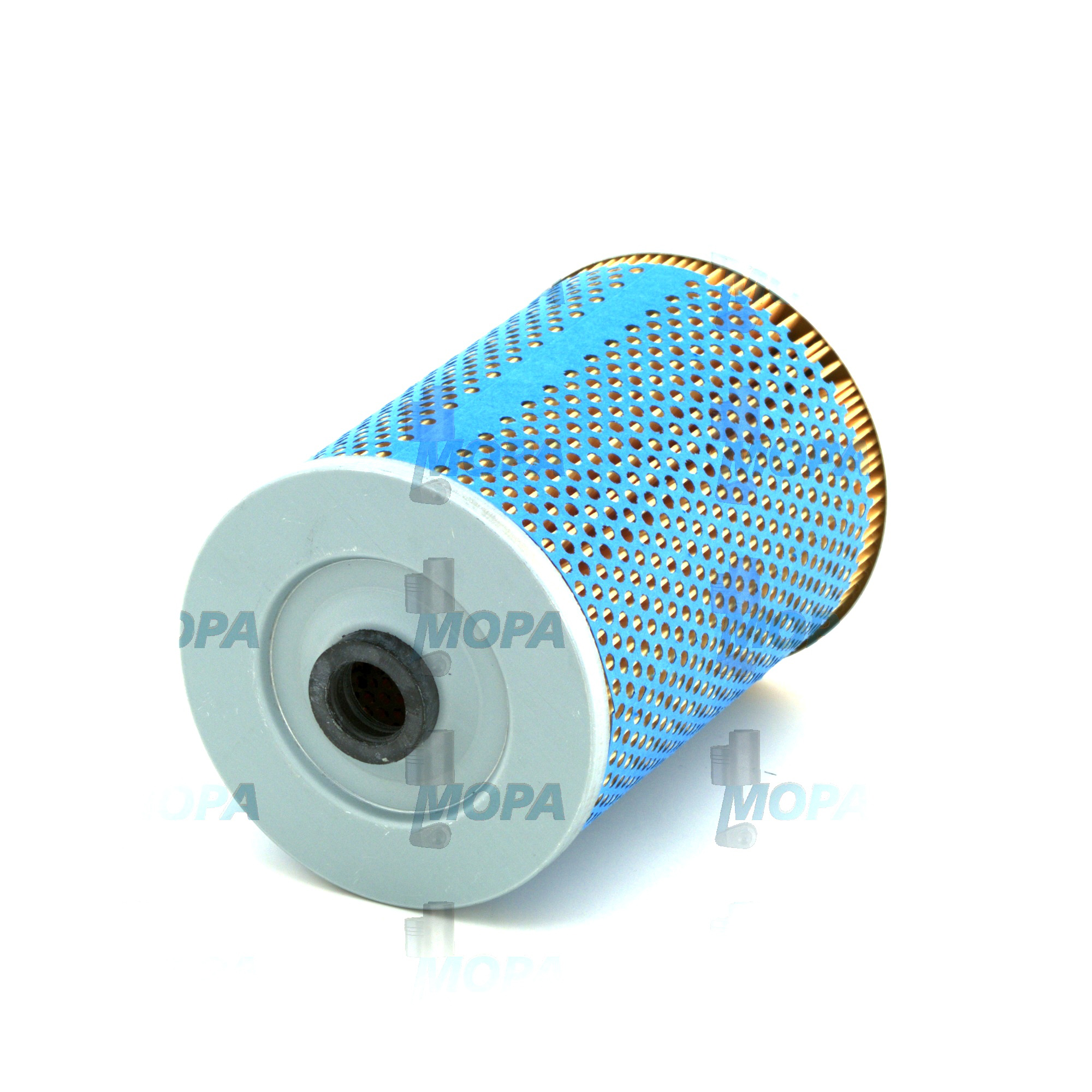

OEM spare parts suitable for TBD620-V12: performance, reliability, service life

For any TBD620-V12 marine engine or genset, parts quality directly influences fuel efficiency, emissions stability, and long-term operating costs. OEM spare parts suitable for TBD620-V12 are manufactured to the dimensional tolerances, material specs, and heat-treatment standards that the engine’s design requires. From pistons, liners, and bearings to injection components and charge-air cooler elements, component integrity ensures proper clearances, controlled thermal expansion, and consistent sealing—factors that protect the cranktrain, reduce wear, and stabilize SFOC over time.

Using OEM spare parts suitable for TBD620-V12 also aligns injector flow rates, governor behavior, and turbocharger matching, which together safeguard load acceptance and keep exhaust temperatures in the intended window. This is particularly important for class-compliant operation and for vessels or plants that cycle frequently between partial and full load. With correct parts and procedures, operators preserve time-between-overhaul targets and avoid unplanned downtime driven by tolerance drift or mismatched subassemblies.

- · Protects performance through precise tolerances and materials.

- · Stabilizes fuel efficiency and emissions over long service intervals.

- · Preserves shaft power and load acceptance under varying conditions.

- · Reduces wear on liners, rings, bearings, and valve train components.

- · Supports class-compliant maintenance records and auditability.

- · Ensures consistent fit with existing TBD620-V12 systems and settings.

MOPA is a reliable partner for OEM spare parts suitable for TBD620-V12. With deep technical know-how on the MWM & Deutz 620 DIESEL platform and responsive logistics, MOPA helps operators secure critical-path components, plan overhauls with confidence, and keep the engine’s performance within design benchmarks. Whether you run a TBD620-V12 diesel engine for propulsion or as a generator prime mover, MOPA’s application support and parts availability streamline maintenance planning and execution.

Conclusion: TBD620-V12 diesel engine with strong lifecycle support

The TBD620-V12 delivers robust torque, reliable efficiency, and service-friendly construction for marine and stationary duty. Its balance of power density and durability explains its widespread adoption across vessels and industrial plants. To sustain that performance, MOPA supplies OEM spare parts suitable for TBD620-V12, helping operators protect reliability, efficiency, and service life over the entire engine lifecycle.