TBG620 gas engine for reliable power and CHP performance

The TBG620 is a proven large-bore gas engine that delivers dependable, efficient power in continuous-duty operation. Positioned within the 620 GAS series from MWM & Deutz, the focus of this engine type is stable output, fuel flexibility, and long service intervals for professional operators. Decision-makers appreciate the TBG620 for its balance of performance and lifecycle economics in demanding applications, from cogeneration to modular power plants and auxiliary power duties.

TBG620 technical characteristics and performance data

The TBG620 is a four-stroke, turbocharged, charge-air-cooled, lean-burn gas engine available in V-type configurations (commonly V12 and V16). It is engineered for continuous operation on natural gas and special gases (biogas, landfill gas, sewage gas), with electronic ignition and precise lambda control for stable combustion and low emissions. Typical generator set speeds are 1,500 rpm for 50 Hz grids and 1,800 rpm for 60 Hz grids. In project documentation, V12 variants are often configured around the 1.2–1.5 MWe class, while V16 variants can be specified up to approximately 2.0 MWe, depending on site conditions, gas quality, and heat recovery setup. In CHP mode, the engine’s lean-burn concept supports high total efficiencies when thermal energy is utilized effectively.

Built on a robust crankcase with optimized cooling oil and water circuits, the TBG620 supports long operating intervals and predictable maintenance planning. Integrated knock detection and mixture control help protect components and sustain efficiency over varying gas qualities. The engine’s response characteristics make it suitable for baseload, peaking within defined limits, and island-mode operation with appropriate controls. For operators evaluating the “TBG620 diesel engine” concept for comparison, it is important to note that the TBG620 is a spark-ignited gas engine; nevertheless, its efficiency and durability benchmarks align with what many expect from heavy-duty diesel platforms.

- · V-type configuration (V12/V16). Four-stroke, turbocharged, lean-burn.

- · 1,500 rpm (50 Hz) or 1,800 rpm (60 Hz) genset operation.

- · Electrical output typically up to ~2,000 kWe for V16 (project-dependent).

- · High total efficiency in CHP through effective heat recovery.

- · Fuel-flexible: natural gas, biogas, landfill and sewage gas.

- · Electronic ignition, lambda and knock control for stable combustion.

- · Designed for continuous duty with long maintenance intervals.

TBG620 applications in power plants and marine auxiliary contexts

The TBG620 is widely applied in industrial cogeneration, municipal utilities, and distributed generation. In CHP configurations, it serves district heating networks, hospitals, universities, food and beverage facilities, and greenhouses (where combined heat and CO₂ utilization can enhance yields). The engine also fits modular power plants, microgrids, and grid-support functions, offering reliable baseload with predictable fuel consumption. In the marine sphere, TBG620 marine engine genset packages are utilized for onboard auxiliary power or harbor-based energy solutions where gas availability and emissions targets favor spark-ignited technology—especially for ferries, offshore accommodation units, and support vessels with electric power modules.

Why operators value the TBG620 from MWM & Deutz:

Its lean-burn combustion and precise controls deliver high efficiency across a range of gas qualities, supporting strong lifecycle economics. The platform’s mature design, together with well-documented service procedures, simplifies overhauls and reduces downtime. Standardized interfaces make integration with modern plant controls and emissions aftertreatment straightforward. For buyers searching phrases such as “TBG620 MWM & Deutz,” “TBG620 marine engine,” or “TBG620 OEM parts,” the engine’s reputation is built on reliable megawatt-class performance, parts standardization, and scalable CHP viability.

Engineering features that support dependable operation

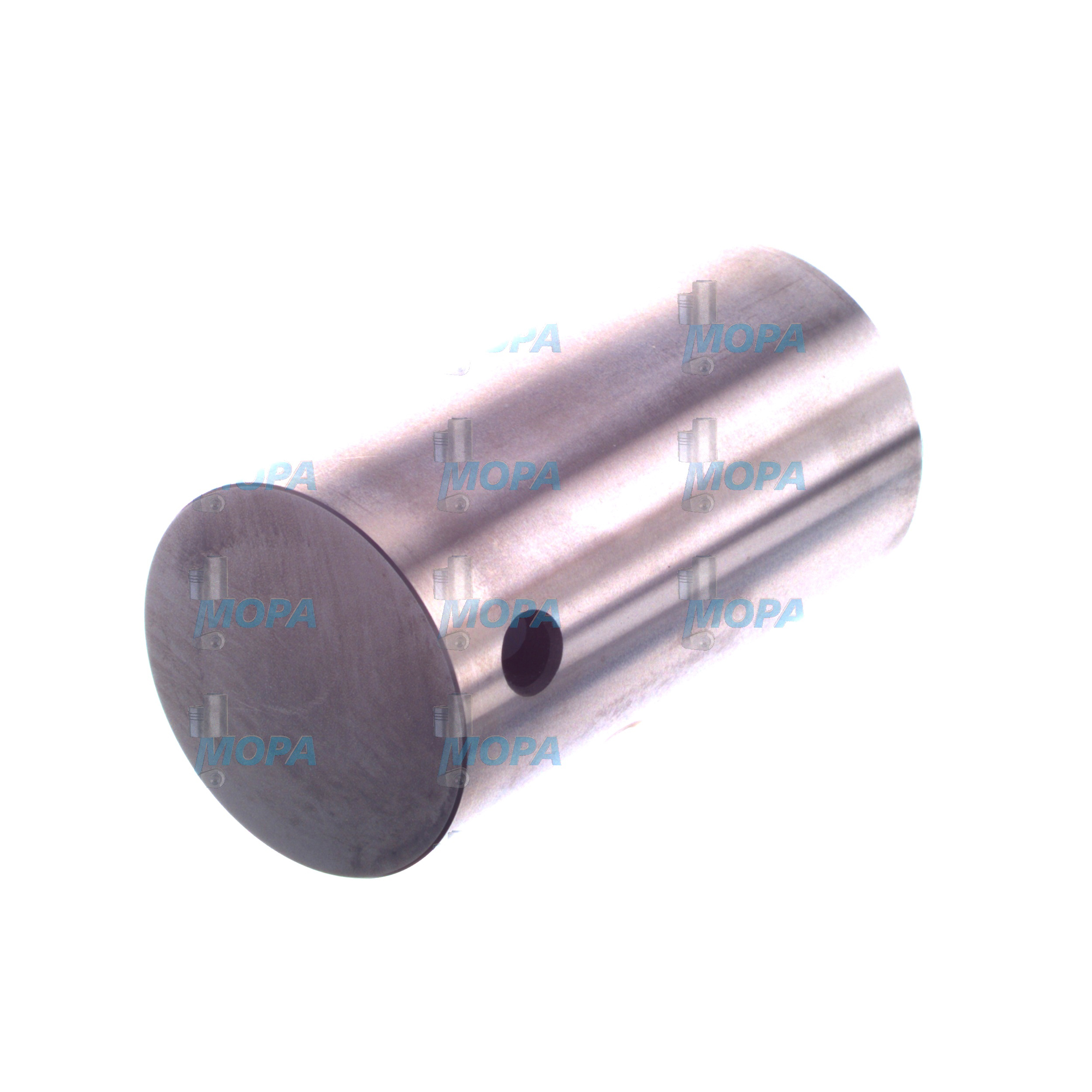

Key design elements include a heavy-duty crankshaft, optimized piston and liner geometries for thermal stability, and efficient charge-air cooling to maintain power density across ambient conditions. Electronic ignition mapping and individual-cylinder monitoring help extend spark plug life and keep emissions consistent. With correctly specified auxiliaries—gas trains, heat exchangers, and emissions controls—the TBG620 sustains continuous baseload output in both 50 Hz and 60 Hz environments, onshore and offshore.

OEM spare parts suitable for TBG620 — performance, reliability, and service life

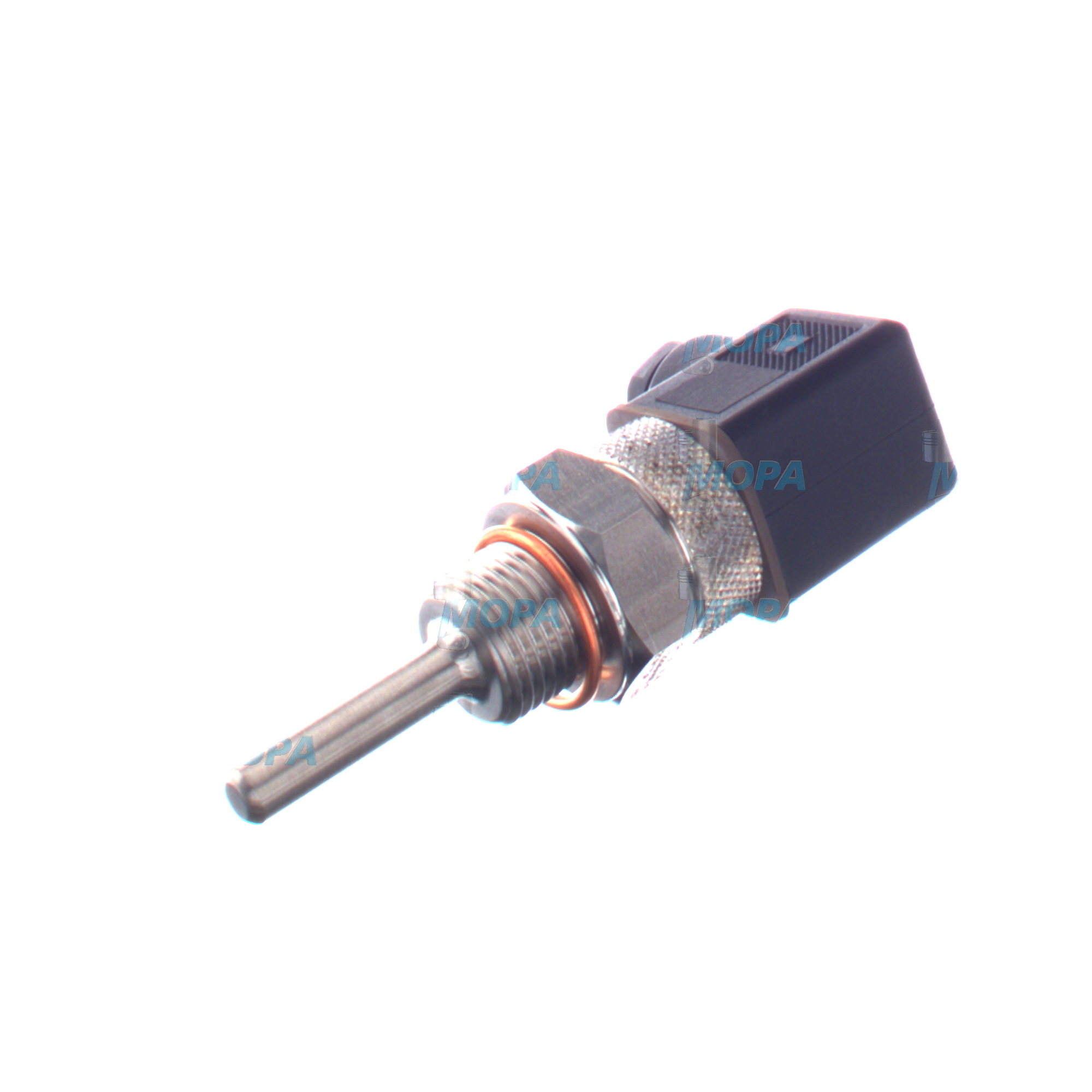

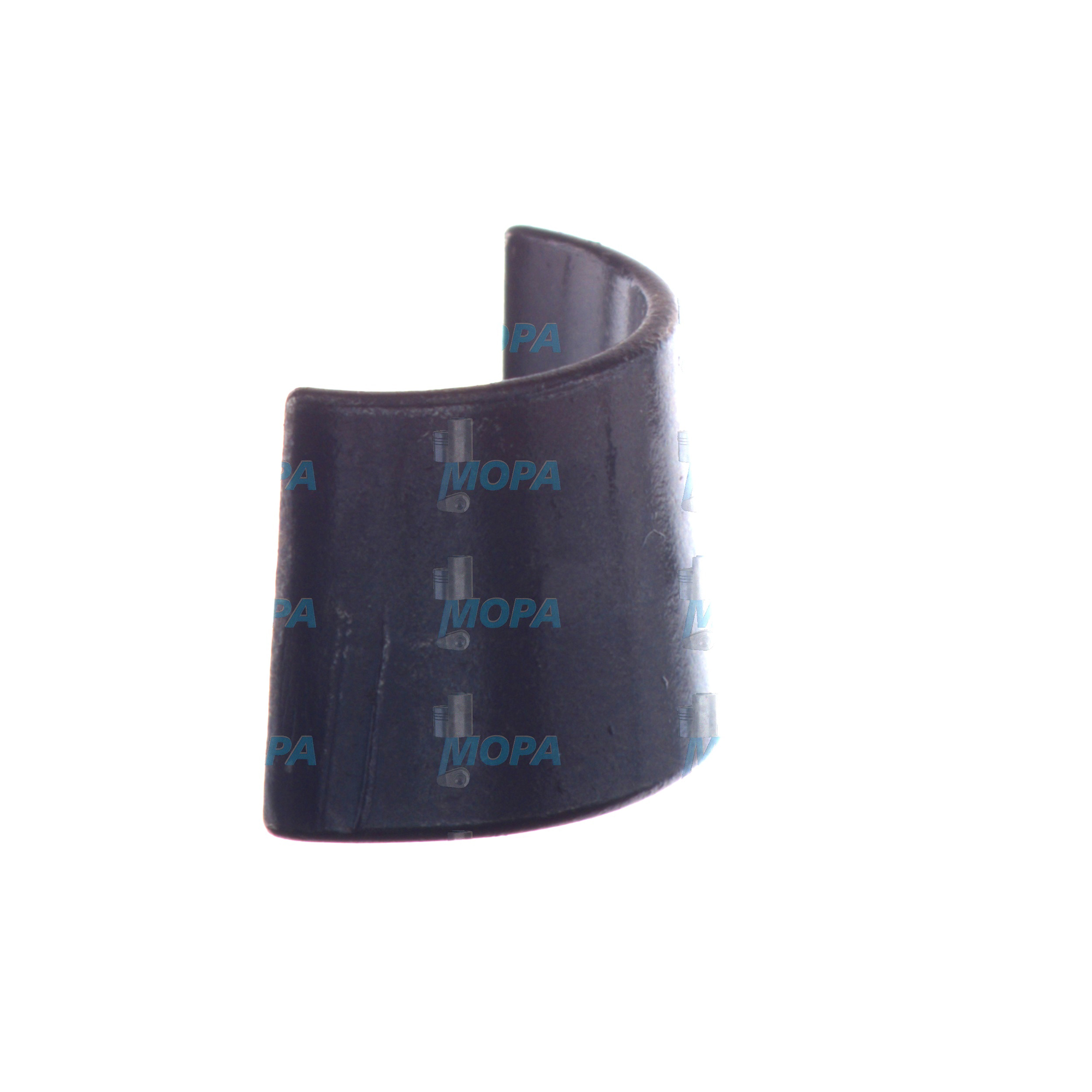

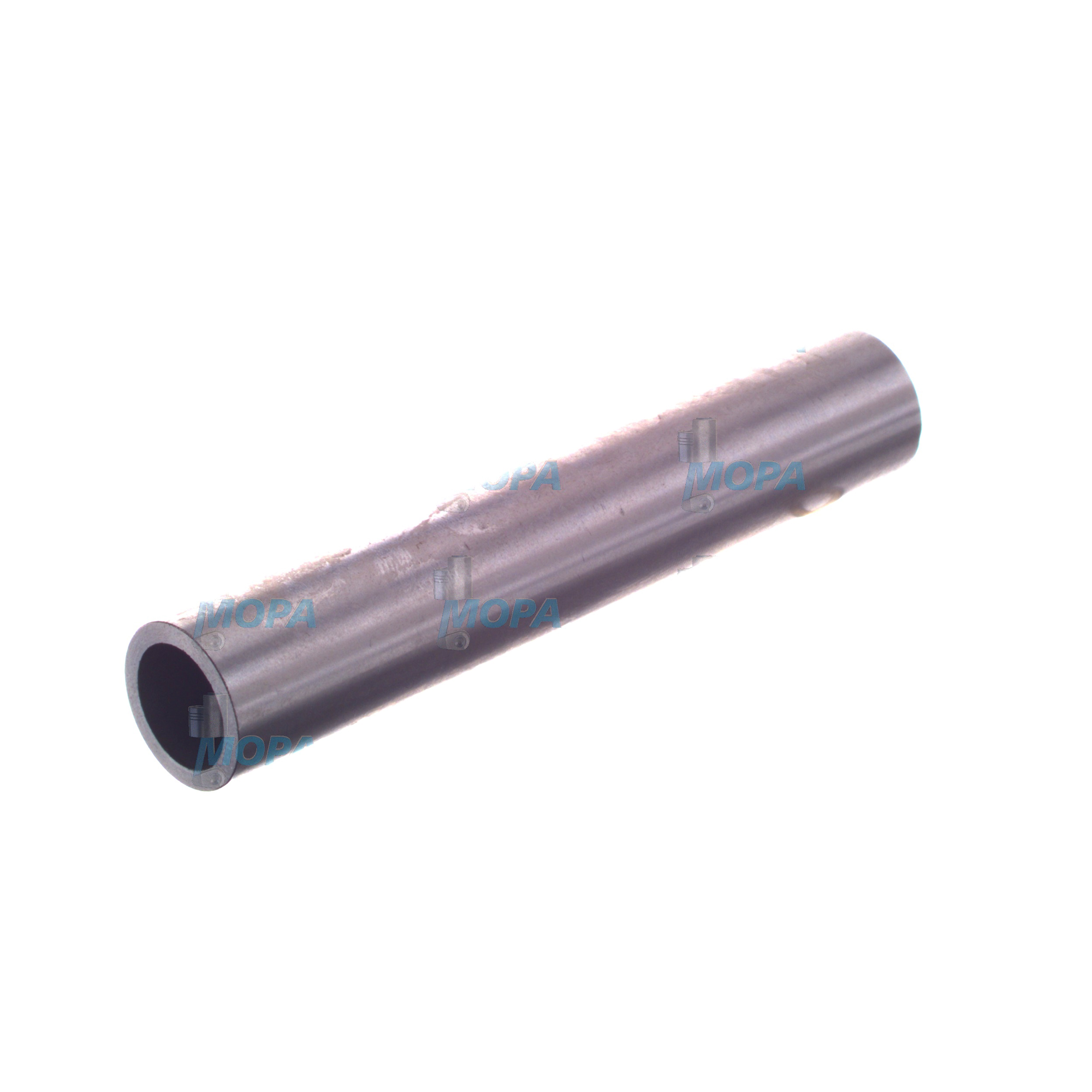

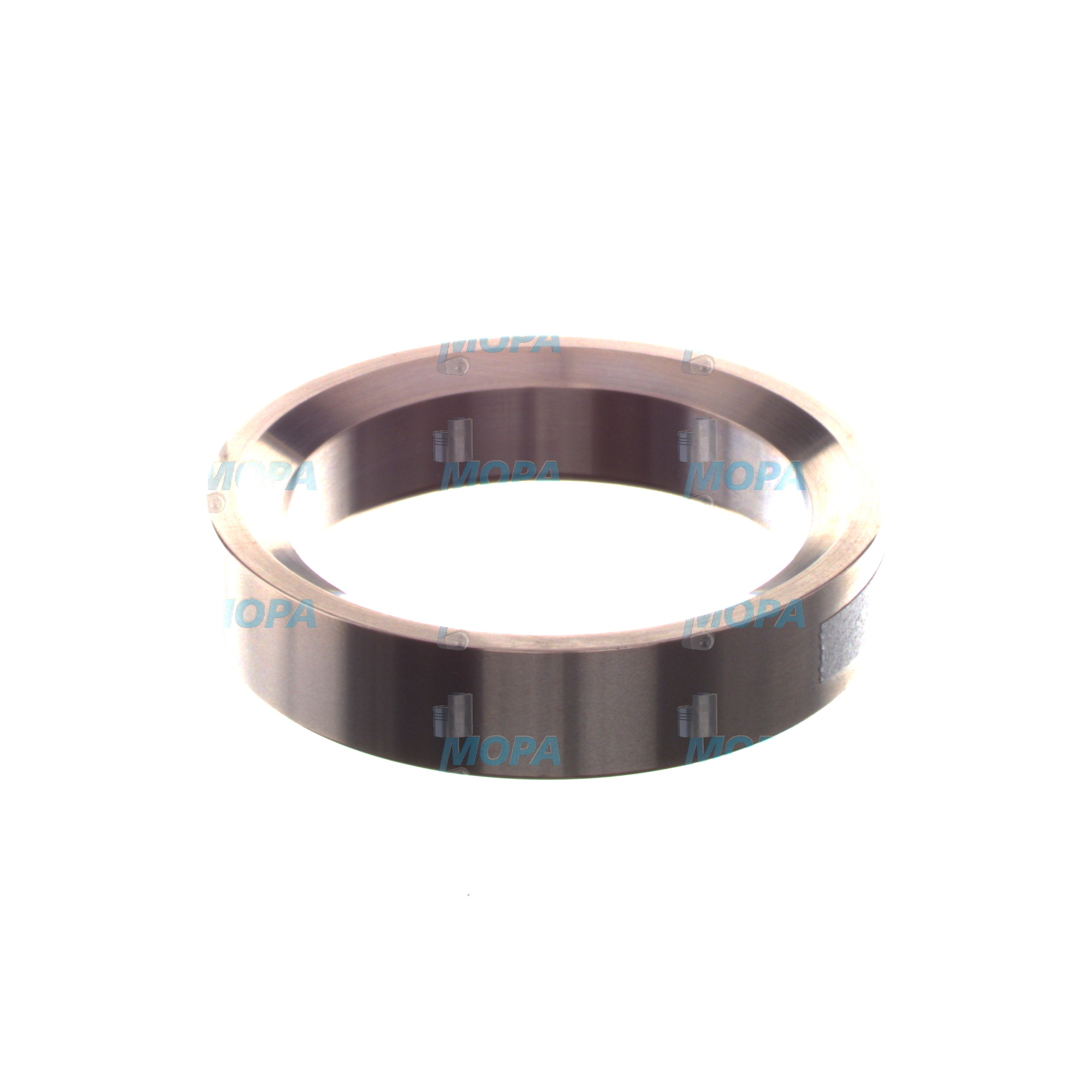

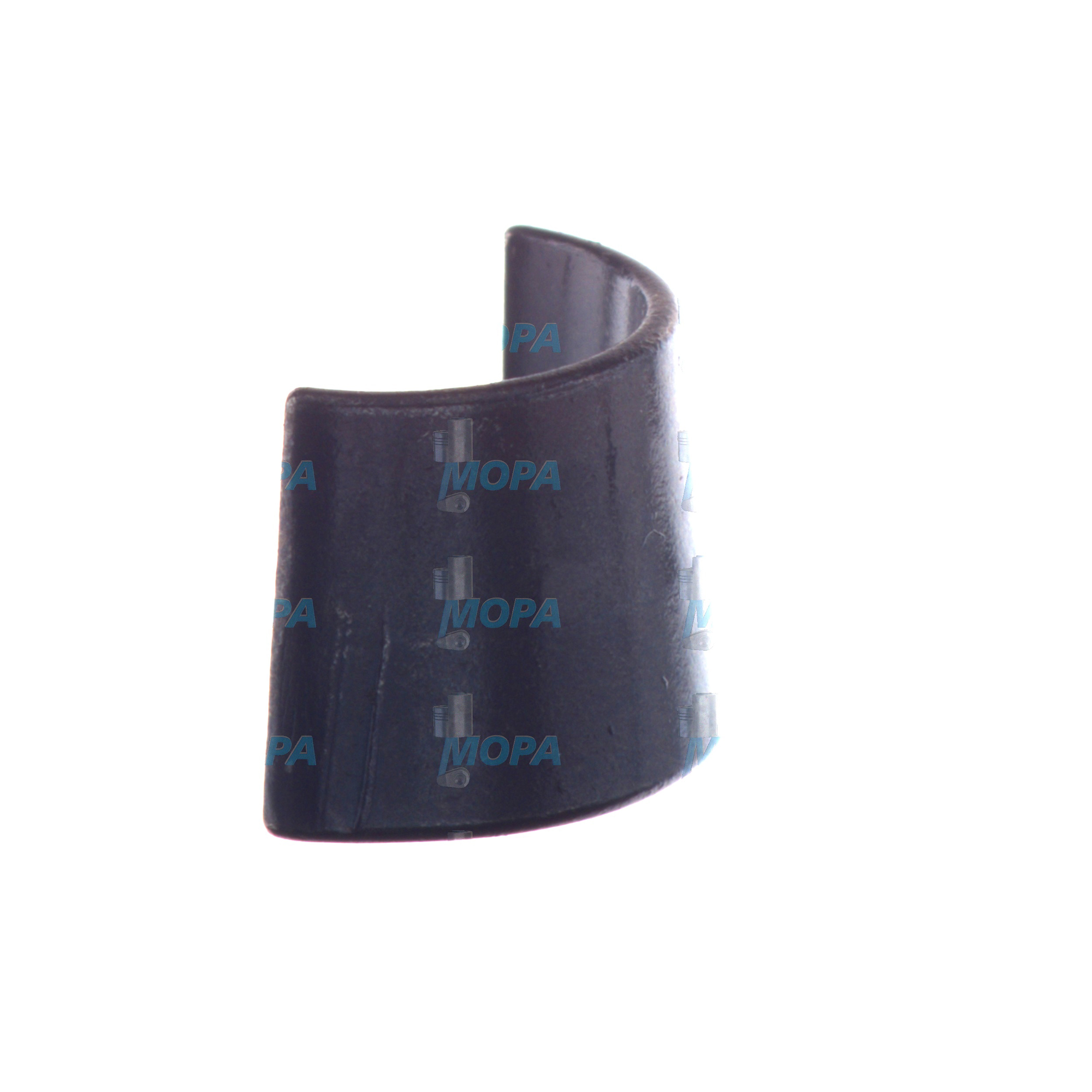

Using OEM spare parts suitable for TBG620 is crucial to preserve combustion stability, fuel efficiency, and emissions conformity. Precision in critical components—such as pistons, cylinder liners, bearings, valves, ignition coils, and sensors—directly impacts wear rates and power balance across cylinders. Correct materials and tolerances uphold clearances, protect against detonation, and maintain oil control, which in turn supports longer service intervals and predictable overhaul planning.

Beyond core components, OEM spare parts suitable for TBG620 ensure that turbocharger performance, charge-air cooling effectiveness, and gas mixing remain within engineered setpoints. This consistency reduces unplanned stoppages, stabilizes heat recovery output in CHP systems, and safeguards catalyst performance where oxidation or other aftertreatments are employed. For marine and offshore deployments, specification-aligned parts also help maintain class approvals and documented service records.

MOPA is a reliable partner for OEM spare parts suitable for TBG620, providing technically validated components, kitting support for scheduled maintenance windows, and responsive logistics aligned with plant or vessel operating calendars. From ignition system packages to gasket sets, valve train components, filtration, and instrumentation, MOPA helps operators keep the TBG620 performing at its engineered capability across multi-year duty cycles.

Why choose MOPA for OEM spare parts suitable for TBG620

MOPA supports purchasers and technical teams with expert parts identification, documentation aligned to engine serial data, and delivery models tailored to outage plans. By standardizing on OEM spare parts suitable for TBG620, operators gain predictable performance, consistent emissions profiles, and a stable total cost of ownership over the engine’s lifecycle.

Conclusion: TBG620 value and assured supply of OEM spare parts

The TBG620 combines robust engineering, fuel flexibility, and high-efficiency CHP capability, making it a trusted choice for power plants, industrial sites, and selected marine auxiliary roles. Its balance of performance and serviceability is why many projects standardize on this engine platform.

MOPA strengthens this proposition with timely delivery of OEM spare parts suitable for TBG620, enabling sustained reliability, optimized efficiency, and long service life throughout your operational schedule.