TBG620-V16K gas engine for high-efficiency power and heat

The TBG620-V16K is a robust, large-bore V16 gas engine engineered for high output, continuous-duty operation and superior fuel utilization. While it belongs to the 620 GAS series from MWM & Deutz, the focus here is the TBG620-V16K itself: a lean-burn, turbocharged prime mover designed to deliver dependable performance across demanding industrial and energy applications. Operators value its balance of power density, efficiency, and long service intervals, especially in combined heat and power (CHP) use where total energy yield is critical.

As a V16 configuration, the TBG620-V16K combines smooth running with low specific emissions and excellent load acceptance. Intelligent engine management enables stable operation on pipeline natural gas and, in many setups, on processed special gases with appropriate approvals. In grid-parallel duty or island mode, the engine’s proven architecture supports reliable base-load generation, fast restarts, and consistent output across varying ambient conditions.

Technical profile and performance of the TBG620-V16K

The TBG620-V16K is built around a 16-cylinder, V-arranged, ignition-controlled design with high-efficiency turbocharging and intercooling. The lean-burn combustion strategy reduces NOx formation at source, while an optimized cylinder head and valve train design support high compression ratios and stable long-term performance. Typical generator-set configurations operate at 1,500 rpm (50 Hz) or 1,800 rpm (60 Hz), providing electrical outputs in the multi‑megawatt class—commonly around 2–4 MW depending on configuration, fuel composition, and site conditions. In CHP installations, total system efficiency can reach very high levels thanks to effective heat recovery from jacket water and exhaust energy.

Engine management integrates knock control, cylinder-specific ignition timing, mixture regulation, and comprehensive protection logic. This helps safeguard pistons, liners, and turbochargers during transients and under varying methane numbers. Compared with a comparable diesel engine in generator duty, the gas-fueled TBG620-V16K can offer significant advantages in local emissions, especially where low-NOx operation and reduced particulate output are strategic objectives.

- · V16 configuration; smooth power delivery and high power density.

- · Lean-burn gas combustion with electronic knock control.

- · Turbocharged and intercooler-equipped for consistent performance.

- · Typical 1,500/1,800 rpm for 50/60 Hz power generation.

- · Multi‑megawatt electrical output class (site and fuel dependent).

- · CHP-ready with high total system efficiency.

- · Low NOx potential; reduced particulate compared with diesel engine duty.

- · Stable baseload and excellent part-load behavior.

Applications: TBG620-V16K in power plants and marine engine contexts

In stationary power generation, the TBG620-V16K is widely applied in industrial cogeneration plants, district heating networks, greenhouse energy systems, wastewater treatment facilities (using treated biogas), and independent power producer (IPP) sites. Its strong performance at continuous load makes it ideal for baseload and peak shaving, while the engine’s control philosophy supports quick synchronization and precise load sharing in multi‑set plants.

For maritime and offshore stakeholders, the TBG620-V16K marine engine context typically involves gas-fueled auxiliary power where infrastructure and certification permit. Use cases include offshore platforms with gas availability and specialized vessels with onboard gas systems. Thanks to its 50/60 Hz capability, fleets requiring standardized power blocks can integrate the TBG620-V16K into modular containerized solutions or engine rooms designed for efficient maintenance and lifecycle planning. Procurement teams often evaluate the TBG620-V16K alongside diesel engine packages to meet emissions targets and optimize total cost of ownership.

Why operators value the TBG620-V16K

Beyond output and efficiency, the TBG620-V16K stands out for its steady operation on varying gas qualities (within specified limits), its robust mechanical design, and its strong service ecosystem. The combination of electronic control, high-grade materials in hot‑gas path components, and a well-documented maintenance philosophy supports predictable overhaul cycles and high availability. These attributes make the TBG620-V16K by MWM & Deutz a preferred choice for mission-critical power: data-driven monitoring and trending enable proactive maintenance, while standardized interfaces simplify integration with plant supervisory systems. For search visibility and procurement alignment, many buyers reference phrases like “TBG620-V16K MWM & Deutz,” “TBG620-V16K marine engine,” and “TBG620-V16K OEM parts” when specifying or maintaining their assets.

OEM spare parts suitable for TBG620-V16K

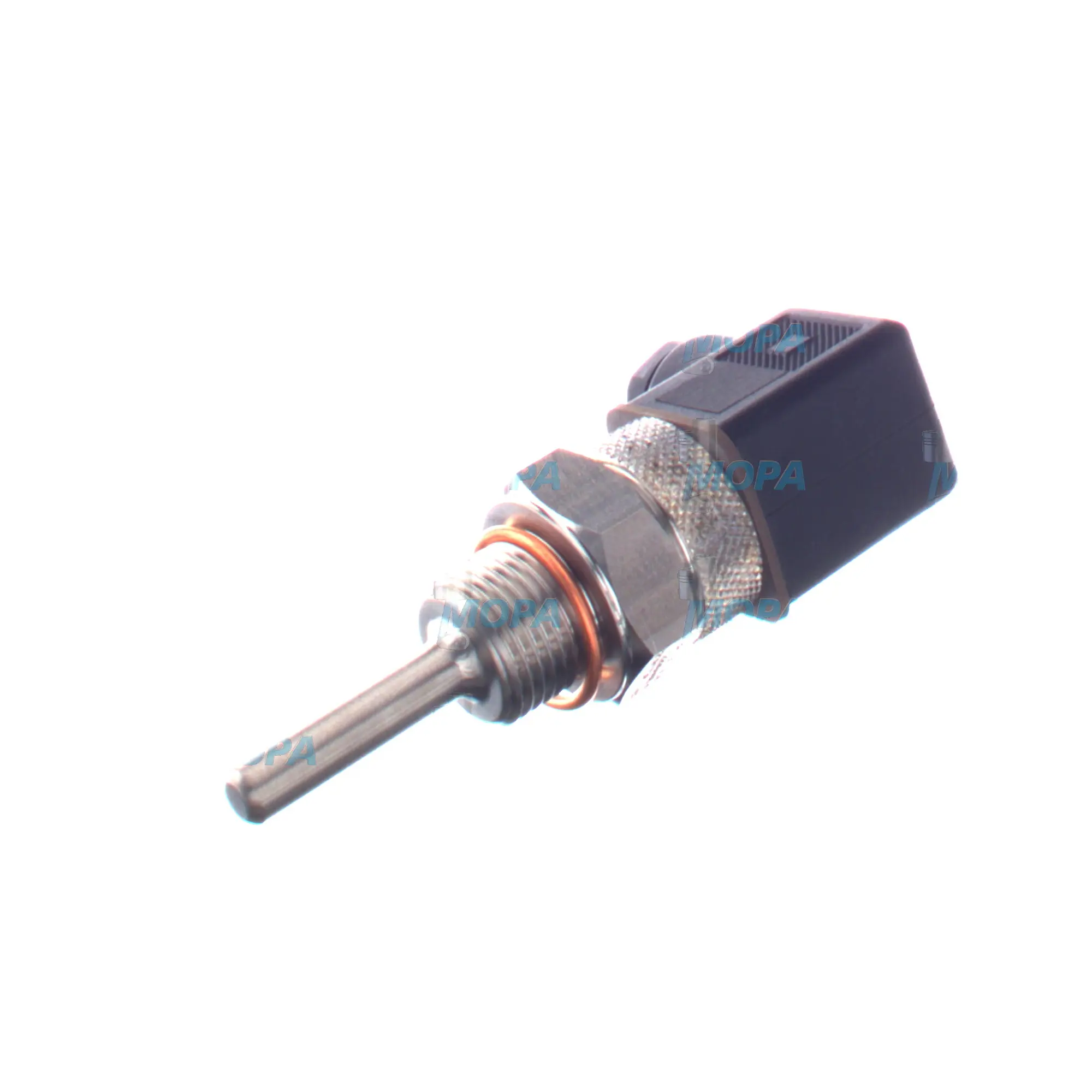

Protecting performance, reliability, and service life hinges on using OEM spare parts suitable for TBG620-V16K. Precision-matched components—such as pistons, rings, cylinder liners, cylinder heads, valve train elements, turbocharger cartridges, ignition modules, spark plugs, gas admission valves, sensors, and sealing sets—are engineered to the tolerances, materials, and heat-resistance required by this engine’s combustion and thermal profiles. This dimensional and material fidelity helps maintain emissions conformity, preserve efficiency, and reduce unplanned downtime.

OEM spare parts suitable for TBG620-V16K support consistent combustion quality across cylinders, ensuring balanced thermal loading and minimizing knock risk. Correct metallurgy in exhaust valves and seats, along with proven coatings and surface treatments, underpins extended intervals between top-end maintenance. Equally, matching turbocharger and intercooler components sustain the charge-air characteristics needed for stable lean-burn operation, especially during seasonal temperature swings or rapid load changes.

MOPA is a reliable partner for OEM spare parts suitable for TBG620-V16K. With application expertise across the MWM & Deutz 620 GAS platform, MOPA helps operators streamline parts planning, set optimal reorder points, and align maintenance windows with production schedules. From routine consumables to major overhauls, MOPA’s supply of OEM spare parts suitable for TBG620-V16K supports predictable lifecycle costs and high plant availability.

Conclusion: TBG620-V16K performance with assured supply

The TBG620-V16K combines V16 power, lean-burn efficiency, and proven reliability for CHP plants, industrial generation, and select marine and offshore applications where gas is the preferred fuel. Its stable output, low-emission profile, and integration flexibility make it a compelling choice for operators focused on long-term energy performance.

For sustained reliability and uptime, MOPA provides OEM spare parts suitable for TBG620-V16K—ensuring that each component aligns with the engine’s engineering requirements and helps preserve performance, efficiency, and service life over the entire operational horizon.