BVM628 marine engine for demanding propulsion and power generation

The BVM628 is a proven medium‑speed engine type recognized for its durable design and consistent performance in continuous duty. Originating from the 628 series by MWM & Deutz, the BVM628 has earned its reputation in fleets and industrial installations where uptime, fuel efficiency, and serviceability are critical. While the series context underscores the engine’s heritage, the focus here is the BVM628 itself: a robust V‑configuration diesel platform engineered for reliable marine propulsion and auxiliary power, as well as stationary operation in land‑based power plants.

BVM628 diesel engine: technical characteristics and performance profile

The BVM628 is a V‑type, turbocharged, charge‑air‑cooled diesel engine developed for heavy‑duty operation. It is commonly available in multiple cylinder counts to match output requirements, with total power ratings scalable into the multi‑megawatt class depending on configuration, application, and rating. Typical operating speeds are in the medium‑speed range, suitable for direct mechanical drive with reduction gearboxes or as prime movers for alternators in marine genset configurations. In marine service, the BVM628 supports both main propulsion and auxiliary power, while in stationary settings it serves base‑load or peak‑shaving roles in power generation.

Core technical characteristics include a high‑rigidity crankcase, replaceable cylinder liners, durable pistons and rings designed for long intervals between overhauls, and robust fuel‑injection equipment optimized for stable combustion across a wide load range. The BVM628 diesel engine is often configured to operate on marine diesel oil and, when specified, on heavier fuel grades with appropriate fuel treatment and heating systems. Efficient turbocharging and charge‑air cooling promote better specific fuel consumption and thermal loading control, which translates into dependable operation under continuous duty.

Why it is valued in the field: the BVM628 combines proven mechanics with accessible maintenance concepts. Its modular assemblies—cylinder heads, injection equipment, turbochargers, pumps, and coolers—are designed for straightforward inspection and replacement during planned maintenance. The engine’s balance of power density and serviceability allows operators to achieve predictable lifecycle costs while meeting operational schedules in shipping and power generation.

Typical applications of the BVM628 marine engine

In maritime environments, the BVM628 is well suited for cargo vessels, tankers, passenger ferries, offshore supply vessels, tugs, and specialized workboats. Its steady torque characteristics and medium‑speed operation make it a reliable choice for both propulsion and shipboard power generation. Ashore, the BVM628 powers industrial and utility installations as a stationary genset, supporting island grids, remote sites, and combined heat and power (CHP) solutions where consistency and maintainability are paramount.

Procurement teams and technical managers appreciate the platform for its lifecycle economics and the availability of BVM628 OEM parts through established supply channels. Whether referenced as a BVM628 marine engine by MWM & Deutz or a BVM628 diesel engine for stationary use, it remains a dependable workhorse in multi‑sector operations.

- · Robust V‑configuration for continuous duty in marine and stationary applications.

- · Medium‑speed operating range for propulsion and genset roles.

- · Scalable output into the multi‑megawatt class depending on cylinder count and rating.

- · Turbocharged and charge‑air‑cooled for efficient combustion and fuel economy.

- · Service‑friendly modular components for planned maintenance.

- · Flexible fuel capability when properly configured and treated.

BVM628 in real‑world service: reliability and efficiency

On cargo and passenger vessels, the BVM628 marine engine delivers steady propulsion power with responsive load acceptance, aiding maneuvering and harbor operations. As an auxiliary engine, it provides dependable electrical power for ship systems and hotel loads. In power plants, the BVM628 is commonly operated at optimized load bands to maximize efficiency and minimize specific fuel consumption. Operators often select the platform for its proven track record and the straightforward availability of BVM628 OEM parts and technical support.

From a lifecycle perspective, the engine’s design focuses on predictable overhaul intervals, clear condition‑monitoring points (exhaust temperatures, vibration, lube oil analysis), and standardized procedures that help reduce downtime. The result is an engine type valued for its balance of output, endurance, and maintainability.

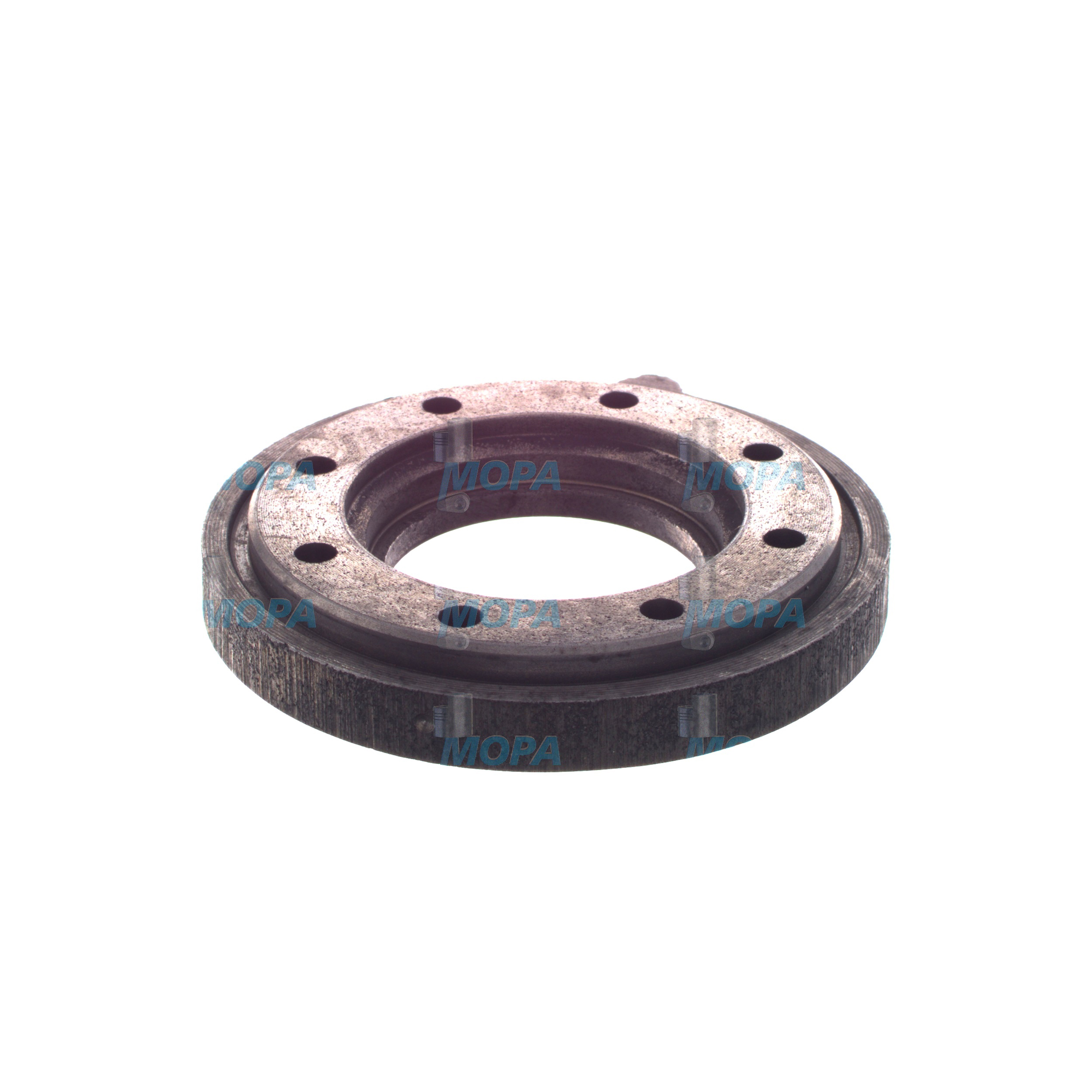

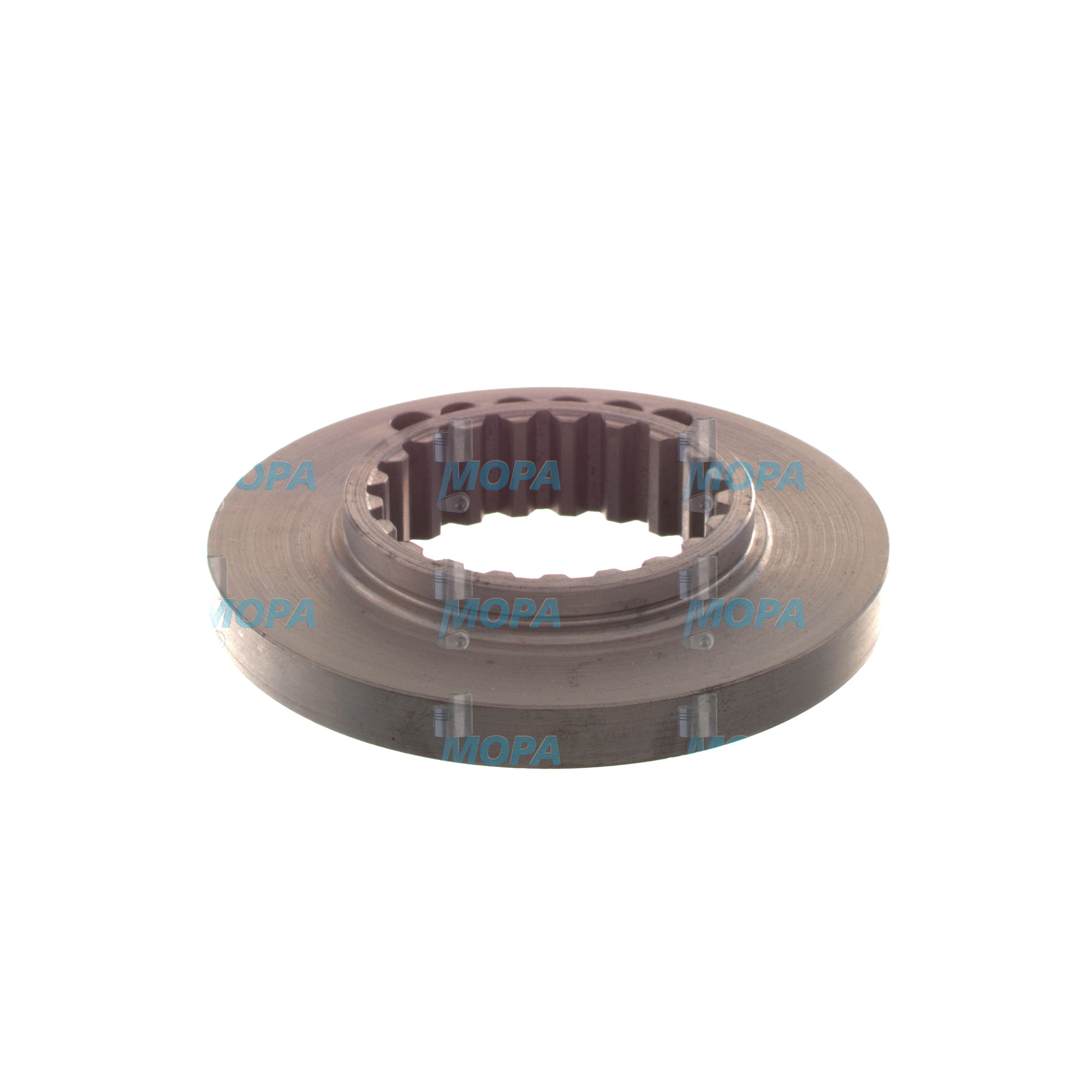

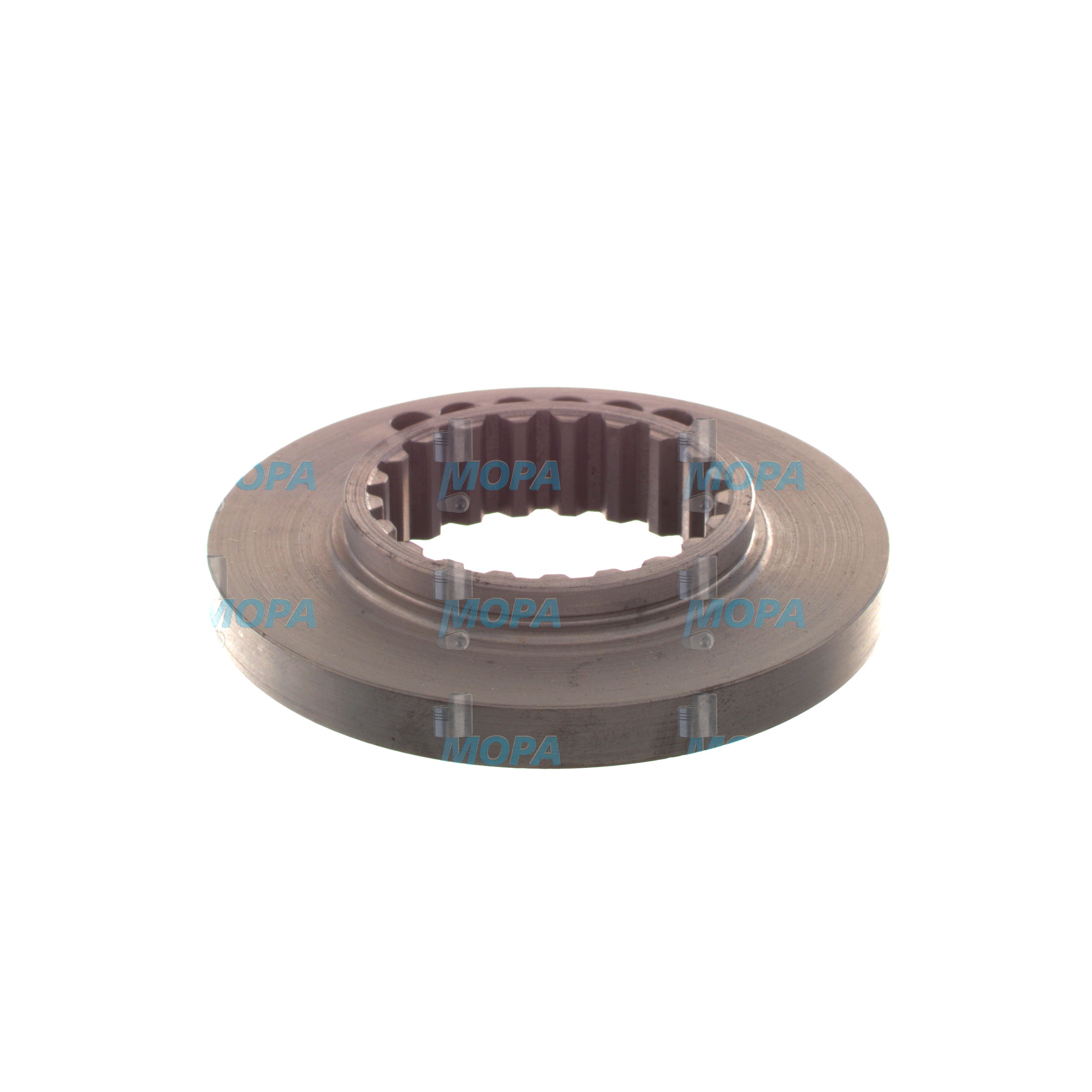

OEM spare parts suitable for BVM628: performance, reliability, service life

To preserve the intended performance envelope of the BVM628, it is essential to rely on OEM spare parts suitable for BVM628. Precision‑manufactured components—such as cylinder liners, pistons, rings, cylinder heads, valves, fuel‑injection equipment, water and lube‑oil pumps, filters, charge‑air coolers, turbochargers, bearings, and sealing sets—directly influence combustion quality, thermal balance, and mechanical integrity. Using OEM spare parts suitable for BVM628 ensures that material specifications, machining tolerances, and surface treatments align with the engine’s design parameters. The outcome is stable output, consistent emissions performance, and longer service intervals under the prescribed maintenance regime.

MOPA is a reliable partner for OEM spare parts suitable for BVM628. Purchasers and technical teams benefit from documented traceability, fit‑for‑purpose engineering, and dependable logistics—key factors when planning dry‑dock periods, voyage repairs, or scheduled shutdowns in power plants. With correct parts selection and adherence to service bulletins, operators can optimize total cost of ownership while maintaining system availability.

- · Maintain as‑designed clearances and tolerances for critical components.

- · Protect efficiency through matched turbocharging and charge‑air‑cooler performance.

- · Support reliable injection timing and spray patterns for clean combustion.

- · Extend overhaul intervals with durable liners, rings, and bearings.

- · Reduce unplanned downtime via consistent parts quality and specification control.

- · Streamline maintenance planning with documented parts traceability.

Service practices that enhance the BVM628 with OEM parts

Combining OEM spare parts suitable for BVM628 with best‑practice maintenance yields measurable benefits. Align parts replacement with condition‑based monitoring, keep fuel conditioning and lube‑oil quality within specification, and follow correct torques and tightening sequences for cylinder heads and main bearings. Verify charge‑air cooler cleanliness, maintain injector calibration, and balance turbocharger performance to the rated load profile. These steps sustain the BVM628 diesel engine’s efficiency and reliability across marine and stationary cycles.

Conclusion: BVM628 value and secure parts supply

The BVM628 stands out as a dependable medium‑speed solution for propulsion, auxiliary power, and stationary generation—combining robust mechanics, efficient turbocharging, and service‑friendly design. Its track record across fleets and power plants reflects consistent output, predictable maintenance, and strong lifecycle economics.

To preserve these strengths, rely on OEM spare parts suitable for BVM628, with MOPA as your trusted source for timely supply and technical guidance. This approach safeguards engine performance, reliability, and service life throughout demanding operational schedules.