SBV9M628L

SBV9M628L marine engine performance, applications, and OEM parts

The SBV9M628L stands out as a robust medium-speed V-engine engineered for demanding marine and stationary duties. While it belongs to the 628 series from MWM & Deutz, the focus here is squarely on what the SBV9M628L delivers in real-world operation: strong torque at low and mid speeds, dependable continuous ratings for propulsion and power generation, and a design that balances fuel efficiency with long service intervals. In fleets that prioritize uptime and predictable lifecycle costs, the SBV9M628L diesel engine has earned a reputation for durability and consistent output across diverse operating profiles.

Whether specified for main propulsion or configured as a genset prime mover, the SBV9M628L marine engine combines turbocharging, charge-air cooling, and a proven V-configuration to achieve stable combustion and low specific fuel consumption. Common installations pair the engine with controlled cooling circuits, heavy-fuel or marine diesel fuel systems (depending on build), and automation that simplifies watchkeeping. As a result, operators see reliable starts, steady load acceptance, and clean operations aligned with contemporary compliance standards on oceans and rivers alike.

Technical profile of the SBV9M628L by MWM & Deutz

The SBV9M628L is a 9‑cylinder V-configuration, medium-speed diesel engine designed to provide multi‑megawatt class output depending on rating and setup. It typically operates in speed ranges aligned with marine and generator standards—commonly in the vicinity of 720–1000 rpm—allowing direct coupling to propulsion gearboxes or alternators for 50/60 Hz electrical systems. Turbocharging with efficient charge-air cooling supports high mean effective pressure and robust torque, while fuel system variants accommodate marine diesel oil and, in appropriate configurations, heavy fuel oil with the required treatment systems.

Key construction features include a rigid crankcase designed for long-term alignment integrity, efficient lubrication and cooling circuits, and component accessibility that simplifies planned maintenance. Depending on the build era and specification, injection technology may range from precision mechanical systems to electronically managed solutions that refine timing and enhance fuel economy. Emission performance can be further optimized through available aftertreatment or tuning packages, supporting compliance strategies without compromising output stability.

- · 9-cylinder V-configuration for balanced power delivery.

- · Medium-speed operation, typically around 720–1000 rpm.

- · Turbocharged and charge-air cooled for high efficiency.

- · Durable block and cranktrain for long TBOs.

- · Proven as SBV9M628L marine engine and genset prime mover.

- · Flexible fuel handling; MDO and HFO-ready configurations where specified.

- · Strong load acceptance for auxiliary and propulsion duties.

- · Supported by SBV9M628L OEM parts and service expertise globally.

Applications of the SBV9M628L marine diesel engine

Shipowners and technical managers value the SBV9M628L for its versatility across propulsion and auxiliary roles. In propulsion, it is frequently paired with reduction gearboxes driving fixed-pitch or controllable-pitch propellers on cargo vessels, passenger ferries, dredgers, and offshore support vessels. In auxiliary and diesel-electric configurations, the SBV9M628L by MWM & Deutz powers alternators supplying hotel loads, drilling packages, and DP systems, where steady frequency control and fast transient response are essential.

Beyond maritime use, the SBV9M628L diesel engine is found in stationary power plants and industrial sites, where it supports continuous or prime power applications. Here, the engine’s medium-speed profile and efficient thermal management translate into attractive fuel efficiency and predictable maintenance scheduling—key considerations for remote installations and island grids. The engine’s component quality and robust design help it withstand cyclical load regimes and extended baseload operation alike.

These characteristics explain why the SBV9M628L is widely adopted: it provides a strong combination of mechanical simplicity, service accessibility, and stable performance. With the right upkeep—and the right SBV9M628L OEM parts—operators sustain target efficiencies and extend overhaul intervals, reducing total cost of ownership over the life of the asset.

OEM spare parts suitable for SBV9M628L: performance and lifecycle benefits

Keeping an SBV9M628L performing to specification hinges on the quality and precision of components installed during routine service and overhauls. OEM spare parts suitable for SBV9M628L are engineered to the same dimensions, materials, and tolerances as the components used at build. This alignment preserves combustion quality, maintains clearances within design limits, and supports the thermal balance that underpins efficiency and reliability.

By selecting OEM spare parts suitable for SBV9M628L, purchasers protect critical performance metrics such as specific fuel consumption, exhaust temperature balance, and emissions conformity. Components like injectors, pistons, liners, bearings, pumps, and charge-air system elements must interact as a matched system; even small deviations can affect load response, fuel burn, or oil consumption. Spec-correct parts help retain designed service intervals and predictable maintenance windows, simplifying planning and reducing unplanned downtime risk.

Another advantage is documentation and traceability. OEM spare parts suitable for SBV9M628L come with clear identification and technical data that streamline installation, commissioning checks, and lifecycle tracking—important for class, audits, and internal quality systems. For operators running mixed fleets, this consistency also assists in harmonizing procedures and inventory across vessels or sites.

Why choose MOPA for OEM spare parts suitable for SBV9M628L

MOPA is a reliable partner for OEM spare parts suitable for SBV9M628L. With deep product knowledge of the 628 family and the SBV9M628L in particular, MOPA supports rapid sourcing, clear technical identification, and delivery coordination tailored to drydock or voyage schedules. From combustion components and rotating assemblies to sealing kits and sensors, MOPA helps ensure that each replacement part aligns with the intended rating and fuel setup of your SBV9M628L marine engine.

For superintendents and buyers, this means fewer technical uncertainties, cleaner work scopes, and maintained performance across maintenance cycles. When engines are configured for HFO operation, MOPA can also provide guidance on the correct auxiliary parts—such as preheating, filtration, and conditioning elements—so that the complete system remains within its design envelope.

Conclusion: SBV9M628L benefits and OEM spare parts suitable for SBV9M628L

The SBV9M628L combines the proven architecture of the 628 series with a 9‑cylinder V-layout to deliver dependable power for propulsion, auxiliary, and stationary duties. Its medium-speed efficiency, serviceable design, and steady load handling make it a favored choice for shipowners and plant operators.

To sustain these strengths over time, rely on OEM spare parts suitable for SBV9M628L. MOPA supplies OEM spare parts suitable for SBV9M628L with the technical precision and support that help protect performance, reliability, and service life in your application.

Toric seal 628/37/5/05065289 – Your solution for various engines:Use the toric seal with the comparison number 628/37/5/05065289, an essential component that is optimally suited for Deutz engines. The use of this sealing ring ensures excellent sealing, which secures the performance of engines such as those suitable for SBV12M628, SBV16M628, SBV6M628, and others. This toric seal provides a top-quality solution, especially in the demanding applications of marine and stationary power engineering.

Robust Toric Seal Absolutely IndispensableThe toric seal with the comparison number 628/37/5/05062126 is an essential spare part specifically designed to meet the high demands placed on gaskets in engines. This seal plays a central role in securely containing liquids and gases within the engine, ensuring ultimate reliability for your engines. With precise dimensions of 4.6 cm in length and width, and a height of 0.3 cm, the product is ideally suited for demanding applications in marine and stationary environments.Reliable Functionality with OEM Spare PartsThe toric seal is compatible with various Deutz engines, including SBV12M628, SBV16M628, and SBV9M628. Using OEM spare parts ensures that the toric seal provides the necessary quality that is equivalent to standard parts. This allows you to take advantage of gaskets that are specifically tailored to the needs of your engines.

Toric seal suitable for Deutz engines – Comparison number 628/37/31/05062126The toric seal with the comparison number 628/37/31/05062126 is an essential product for anyone relying on the efficiency and lasting operation of Deutz engines. These gaskets are characterized by outstanding sealing quality, ensuring smooth performance of your engines. As an OEM replacement part, you can be confident that this product meets all the requirements you expect from a reliable engine component.

Floating seal with comparison number 628/37/18/05062126Discover the floating seal with the comparison number 628/37/18/05062126, specifically designed for sealing engines. This seal falls under the category of gaskets and is suitable for MWM & Deutz. It ensures that your engines operate efficiently and increases reliability. Our products, including this spare part, are always associated with high quality.

Toric Seal for Optimal Function of Your EnginesOur toric seal is an essential product for the maintenance of your engines. It is suitable for a variety of Deutz engines, including models 816, CG170, and 628. The optimal fit and durability of these OEM spare parts ensure a perfect seat and prevent leaks. Each dimension has been carefully crafted: with a length and width of 5.9 cm and a height of 0.6 cm, the toric seal is ideal for use in various engine models.

Ergonomic Use of the Floating Seal: Comparison Number 628/37/17/05066280The floating seal with the comparison number 628/37/17/05066280 represents a reliable solution for your needs. This floating seal is suitable for a variety of MWM & Deutz engines of the series 628. Its precise fit ensures effective sealing, which is crucial for the efficient operation of your engines.

Toric seal with comparison number 628/4/3/05065810Discover our toric seal with the comparison number 628/4/3/05065810, a precise OEM spare part specifically designed to meet the requirements of various engines. The toric seal belongs to the category of gaskets and is designed to ensure a reliable seal in various applications. Weighing only 0.021 kg and with compact dimensions of 25.1 cm in length and width and a height of 0.9 cm, this product is ideally suited for diverse use cases.Adaptability to MWM & Deutz enginesThis toric seal is suitable for MWM & Deutz engines and is compatible with both diesel and gas variants, particularly in the series 528, 628, and 620, as well as the model 2032 GAS. Due to its high adaptability, it fits various engine types such as the BA6M528, the BV series, and others. The use of this toric seal enhances the efficiency of your machines and contributes to the longevity of your engines.

Universal Floating Seal Compatible with MWM & DeutzThe floating seal with the reference number 628/37/39/05065289 is an essential part for anyone working with diesel and gas engines. As a product from the gasket category, this floating seal provides reliable sealing for engines in various applications. The reference number 628/37/39/05065289 makes it easy to identify the right replacement and ensure that your engines always meet high standards.

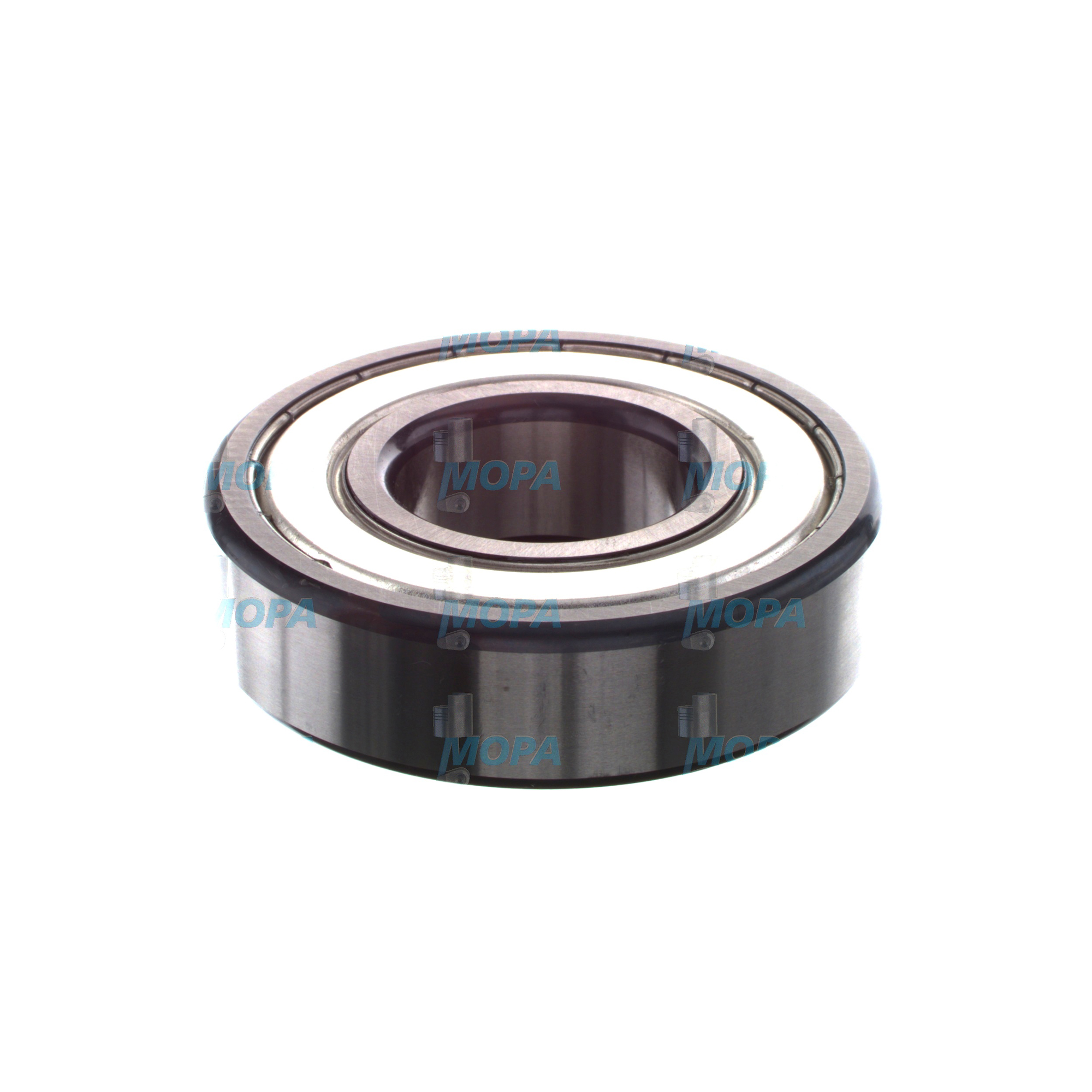

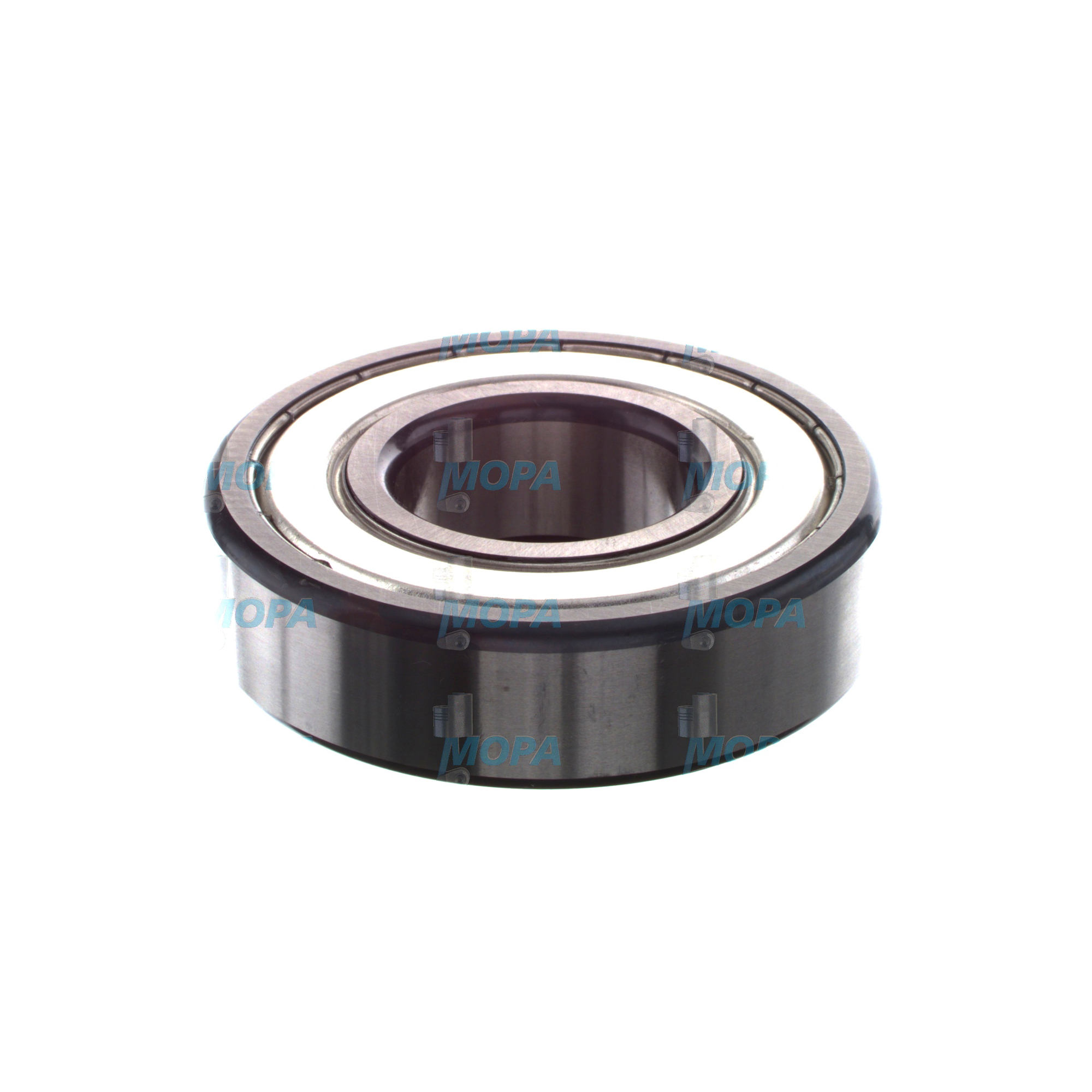

Quality Product: Grooved Ball Bearing for StabilityThe grooved ball bearing with the comparison number 628/37/4/05065289 is an essential product in the world of engine spare parts. This bearing belongs to the item group "Bearings" and stands out due to its performance, especially in applications for MWM & Deutz engines. Optimal specifications and top-notch processing quality make this product an ideal choice for professional users in the industry.Robust Features for Reliable ApplicationsWith dimensions of 9 cm x 9 cm and a height of just 2.4 cm, the grooved ball bearing offers attractive advantages. Weighing only 0.616 kg, installation is simplified. This spare part is suitable for several commonly used engine types, including compatible with SBV12M628, compatible with SBV16M628, and compatible with SBV6M628. Furthermore, it demonstrates excellent performance in various application scenarios, making it highly practical for industrial companies.

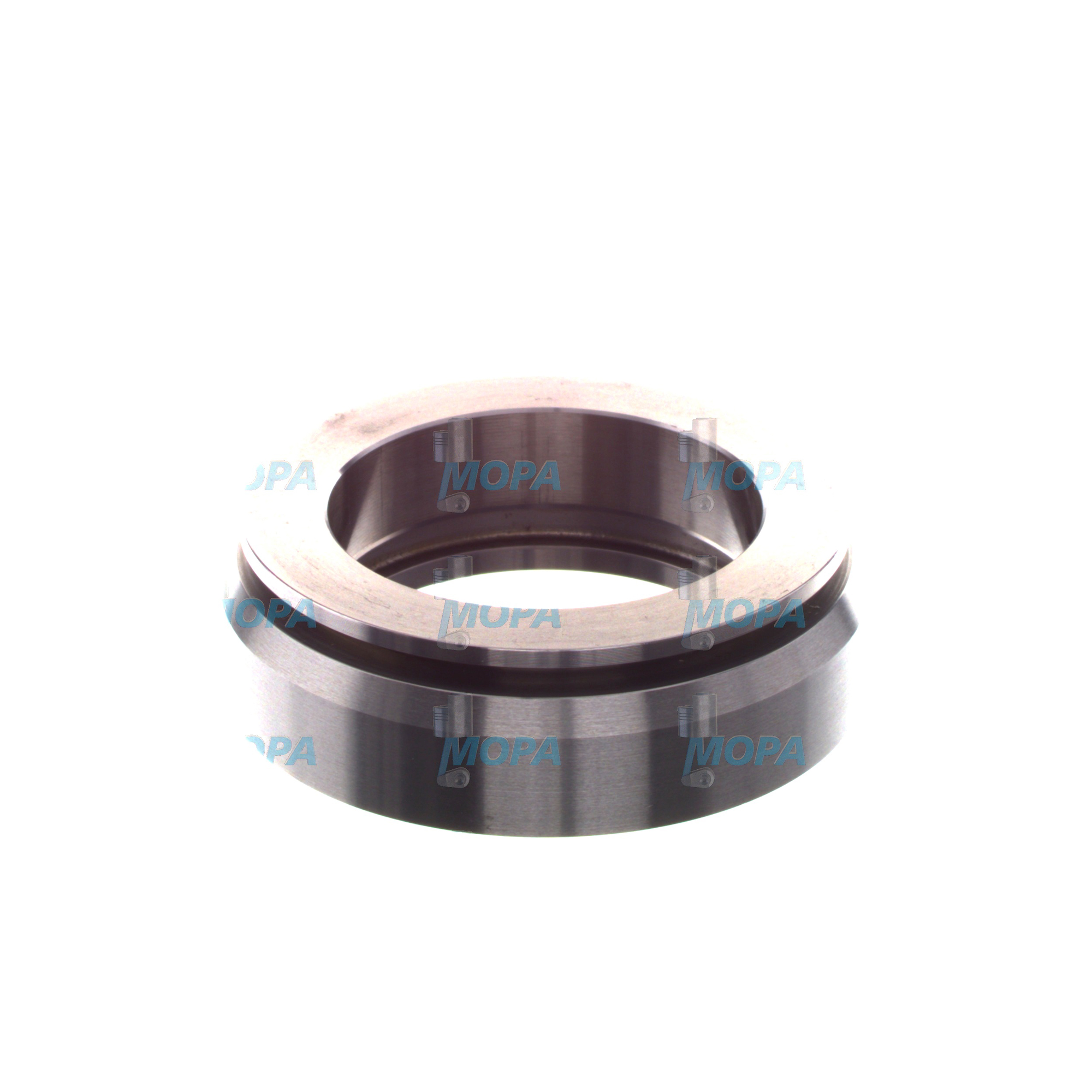

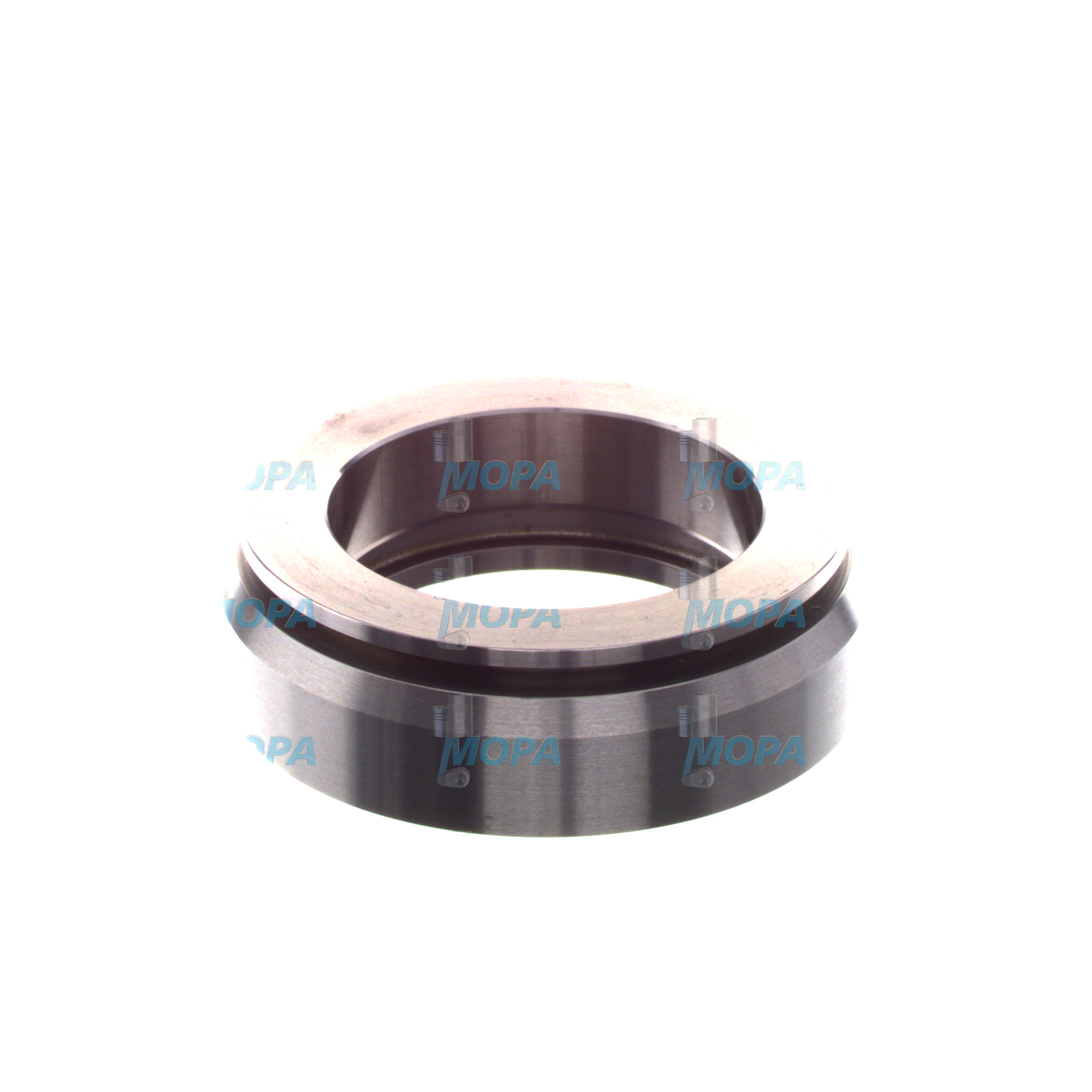

Excellent Spacer Ring for High DemandsChoose our innovative spacer ring, suitable for MWM & Deutz engines, with the comparison number 628/37/6/05065289. This product allows you the excellent performance you expect from an OEM replacement part. It not only fits seamlessly with the series 628 but also offers compatibility with the engine types SBV12M628, SBV16M628, SBV6M628, SBV8M628, and SBV9M628L.Ideally Sized and High QualityOur spacer ring weighs only 0.174 kg and measures 6 cm in length, 6 cm in width, and 2.9 cm in height. Thanks to these compact dimensions, the product is easy to handle and install. OEM stands for Original Equipment Manufacturer, a mark of top-quality assurance that ensures the spacer ring is perfectly suited for MWM & Deutz engines while providing maximum durability.

Floating Seal – Precision Product for Your EngineDiscover the floating seal with the reference number 628/37/39/05066284, which is optimally suited for MWM & Deutz engines. Weighing only 0.079 kg and with compact dimensions of 6.1 cm in length and width and 3 cm in height, this OEM replacement part is specifically designed to ensure reliable performance in the 628 series. The floating seal offers excellent sealing properties that help you maximize the efficiency of your service.Application Areas of the GasketThis gasket is compatible with MWM & Deutz engines such as BV6M628, SBV12M628, SBV6M628, SBV6M628L, SBV8M628, SBV8M628L, SBV9M628, and SBV9M628L. Its construction ensures that operating fluids remain contained within the system, effectively preventing pressure losses. This allows you to meet the high demands placed on the performance of your engines.

Premium Product for Your EnginesDiscover our toric seal with the comparison number 628/37/31/05066284, an essential replacement part for your engines. The toric seal belongs to the group of gaskets and is offered as an OEM replacement part. Due to its perfect fit with various engines, it allows for a seamless integration, enabling you to rely on its functionality and durability.

Floating seal 38.38.0160.035.06: Your sealing solutionThe floating seal with the comparison number 38.38.0160.035.06 is an essential OEM spare part that offers optimal functionality in your engines suitable for MWM & Deutz. This gasket minimizes leaks and ensures highly efficient operation. It has been meticulously designed to seamlessly integrate with the performance of engines suitable for the MWM and Deutz brands.

FLOATING SEAL with the comparison number 02067144 suitable for MWM & Deutz engines

Optimal Solution: Toric seal Comparison Number 6592 for EnginesDesigned to meet the highest standards in engine technology, the toric seal with comparison number 6592 impresses with precision and quality. This product is suitable for engines from the established manufacturers MWM & Deutz and offers exceptional sealing performance. The selection of OEM replacement parts, such as this toric seal, ensures that your engine operates according to specifications.Efficient Gaskets for MWM & Deutz EnginesThis toric seal is specifically compatible with the popular series 816 and 628. Therefore, the product is suitable for various engine types, including BA12M816, BA16M816, BA6M816, BA8M816, SBA12M816, SBA8M816 as well as SBV12M628, SBV6M628L, and SBV9M628L. Rely on OEM replacement parts and benefit from top-notch solutions that not only improve efficiency but also support the longevity of your engines.

Top Quality of the Toric SealEnhance the performance of your engines with our toric seal. This reliable sealing ring has the reference number 628/37/5/05066280 and is a crucial component for the maintenance of your Deutz engines. Handcrafted to the highest standards, this toric seal ensures a perfect seal and helps your drive achieve its full potential.

Product Recommendation: Rotary Shaft Lip Seal 628/37/2/05062126The rotary shaft lip seal with the comparison number 628/37/2/05062126 is an essential OEM replacement part, compatible with Deutz engines. This sealing ring is perfectly suited for the series 628 and the engine types SBV12M628, SBV6M628, SBV9M628, and SBV9M628L. Made from selected materials, the rotary shaft lip seal ensures a reliable seal for your engine, thereby optimizing operational processes.User-Friendly Design and Easy InstallationWeighing only 0.036 kg and featuring compact dimensions of 8 cm in length and width and 1 cm in height, the rotary shaft lip seal is particularly user-friendly. Its small size facilitates installation and maintenance, while the robust construction ensures excellent performance even under extreme conditions. The rotary shaft lip seal ensures that your machine operates efficiently and without interruption.

Efficient Grooved Ball Bearing with Comparison Number 628/37/4/05066280The grooved ball bearing with the comparison number 628/37/4/05066280 is an essential OEM spare part that offers top material quality. This product is designed to meet the requirements of engines that are compatible with MWM & Deutz. Rely on this component to support the optimal operation of your equipment.Versatile: Suitable for MWM & Deutz EnginesThis grooved ball bearing is suitable for numerous engine types, including SBV12M628, SBV16M628, SBV6M628, SBV6M628L, SBV8M628L, SBV9M628, and SBV9M628L. Therefore, it is a versatile OEM spare part that ensures operation in various applications. Whether in the marine sector or stationary applications, this bearing ensures efficient functionality.

Grooved ball bearing suitable for Deutz engines – Comparison number 628/37/14/05062126The grooved ball bearing in the category of OEM spare parts with the specific comparison number 628/37/14/05062126 plays a crucial role in the performance of your machines. This product is suitable for a variety of Deutz engines and offers an optimal fit. The materials used and the construction of this grooved ball bearing ensure the reliability that you can expect from an OEM spare part.Applications of the grooved ball bearingsThis high-quality grooved ball bearing is compatible with several series of the renowned brand, including model ranges such as 816 and 628. It is suitable for engine types BA6M816, SBA12M816, as well as SBV12M628 and many more. With dimensions of 8 cm in length and width, this bearing is a compact and efficient solution in the field of diesel and gas engines. Weighing only 0.442 kg, it is ideal for moving applications in marine and stationary technology areas.

Effective OEM Replacement Part for Engine Performance Discover our valuable product, the spacer ring, which is assuredly compatible with various engines. This OEM replacement part is tailor-made for MWM & Deutz engines. The comparison number 628/37/6/05062107 allows specific requirements and compatibility to be convincingly identified. The quality and reliability come directly from the equipment manufacturer, ensuring lasting performance.Precision and Performance Combined – Suitable for Engines The spacer ring is suitable for MWM & Deutz engines, particularly designed for the series 628. The range of compatible engine types includes SBV12M628, SBV16M628, SBV6M628, SBV8M628, and SBV9M628L. With its compact dimensions of 6 cm x 6 cm and a height of 2.9 cm, this spacer ring offers both stability and optimal functionality. Its lightweight design, weighing only 0.174 kg, ensures a hassle-free installation.

Functional Advantages of a Grooved Ball BearingDiscover our grooved ball bearing, marked with the comparison number 628/37/14/05066284. This product, an OEM replacement component, impresses with top-notch craftsmanship and precision. Our bearings integrate excellently into diesel and gas engines used in modern industrial and marine facilities. The grooved ball bearing is essential to ensure continuous operation of applications.

Precise Grooved Ball Bearing for Efficient EnginesThe grooved ball bearing with the comparison number 628/37/4/05066284 is an essential product that ensures optimal performance for your engines. Manufactured with great precision, this OEM replacement part is ideal for projects in the industrial and marine sectors, ensuring that your high-performance engines from MWM & Deutz operate smoothly.Robust Product Suitable for MWM & Deutz EnginesThis grooved ball bearing, compatible with various models, including the series 628, offers you the excellent quality you can expect from our OEM replacement part. The product is suitable for MWM & Deutz engines SBV12M628, SBV16M628, SBV6M628, SBV6M628L, SBV8M628L, SBV9M628, and SBV9M628L, ensuring that all components work together efficiently. With a weight of 0.616 kg and compact dimensions of 9 cm x 9 cm x 2.4 cm, it is lightweight yet robust.

Spacer Ring for MWM & Deutz Engines in DetailDiscover the spacer ring with the comparison number 628/37/6/05062126, an essential OEM spare part that optimally supports your engine layout. This product belongs to the article group of washers and has been manufactured with precise tuning. It is suitable for MWM & Deutz engines of the series 628, including the engine types SBV12M628, SBV16M628, SBV6M628, SBV8M628, and SBV9M628L – a thoughtful solution that promotes the longevity of your equipment.Technical Data of the ProductThe spacer ring weighs only 0.174 kg and has compact dimensions of 6 cm x 6 cm x 2.9 cm. These dimensions ensure easy installation and a perfect fit in your engine, which is suitable for marine and stationary applications. Due to the high standards of OEM spare parts, you will not have to compromise on quality.

Quality of the spare part with the comparison number 628/37/5/05066284Discover the high quality of our toric seal, which is marked with the comparison number 628/37/5/05066284. This product is an essential component for a variety of applications in engines, specifically suited to your needs. It provides a reliable sealing solution that could make the difference between a well-functioning engine and costly failures.