F6M716 marine engine insights for operators and purchasers

The F6M716 is a proven inline-six diesel that has earned a strong reputation for dependable operation in demanding environments. While it forms part of the 716 series developed by MWM & Deutz, the focus for decision-makers is the specific capability of the F6M716 itself: a compact, robust, and service-friendly power unit that delivers consistent output in marine and stationary roles. Whether specified as a propulsion prime mover for smaller craft or as a generator-drive in auxiliary systems, the F6M716 diesel engine is valued for its durability, fuel efficiency, and straightforward maintenance architecture.

Technical profile of the F6M716 diesel engine

At its core, the F6M716 is a six-cylinder, four-stroke, water-cooled diesel engine designed for long service intervals and stable operation under continuous loads. Depending on configuration, it is available in naturally aspirated or turbocharged versions, with charge-air cooling often selected for higher continuous outputs. Mechanical fuel injection with a precisely matched governor ensures reliable starting, predictable load response, and consistent fuel delivery across the operating range.

Typical continuous-duty characteristics for the F6M716 marine engine include a speed range in the 1,000–1,500 rpm band, giving operators the flexibility to match propeller curves or generator frequencies as needed. In many deployments, continuous power is specified in the low-to-mid hundreds of kilowatts, aligned to Class or project requirements and cooling system layouts. The inline-six layout yields a smooth torque profile with low vibration, a key reason why the F6M716 MWM & Deutz platform is widely selected for auxiliary generation, pumps, and propulsion in smaller vessels where reliability outweighs peak specific output.

Because the F6M716 is part of a well-established 716 family, service uptake and component compatibility are straightforward, which reduces lifecycle cost and simplifies spare parts provisioning. Engine dress options such as marine cooling circuits, heat exchangers, PTO arrangements, and resilient mountings are commonly applied, creating a compact package that is easy to integrate into existing engine rooms and machinery spaces.

Key characteristics of F6M716

· Inline 6-cylinder, four-stroke, water-cooled design.

· Continuous-duty speed typically 1,000–1,500 rpm.

· Naturally aspirated or turbocharged configurations available.

· Mechanical injection for reliable fuel metering and easy service.

· Smooth torque curve suited to propulsion and genset applications.

· Compact footprint and straightforward installation.

· Known for fuel efficiency and long service intervals.

· Strong global service ecosystem and parts availability.

Applications of the F6M716 in marine and stationary operations

The F6M716 diesel engine is frequently specified where dependable power and predictable maintenance are essential. In shipping, it is commonly used as an auxiliary generator drive on cargo vessels, feeder container ships, and offshore support vessels, where steady operation under hotel and process loads is critical. As a propulsion prime mover, the F6M716 marine engine suits coastal freighters, workboats, passenger ferries, pilot boats, and harbor craft that require efficient cruising performance with robust low-end torque.

Beyond the waterfront, the F6M716 is widely applied in stationary roles such as power plant gensets (50/60 Hz), emergency backup systems, pumps, firefighting packages, and industrial drives. Its balanced design allows for reliable operation in both continuous and prime power modes, and its cooling and filtration options handle a broad range of ambient conditions. Fleet operators value the F6M716 MWM & Deutz heritage because it supports unified training, consistent maintenance procedures, and streamlined inventories of F6M716 OEM parts across multiple assets.

Why is this platform so prevalent? The answer lies in the combination of rugged mechanical simplicity with proven component quality. The F6M716’s conservative specific loading, mature fuel system, and robust cooling options emphasize uptime over headline output figures. That design philosophy translates to fewer unplanned stops, predictable service planning, and a favorable total cost of ownership for shipowners and plant operators alike.

OEM spare parts suitable for F6M716: performance, reliability, and service life

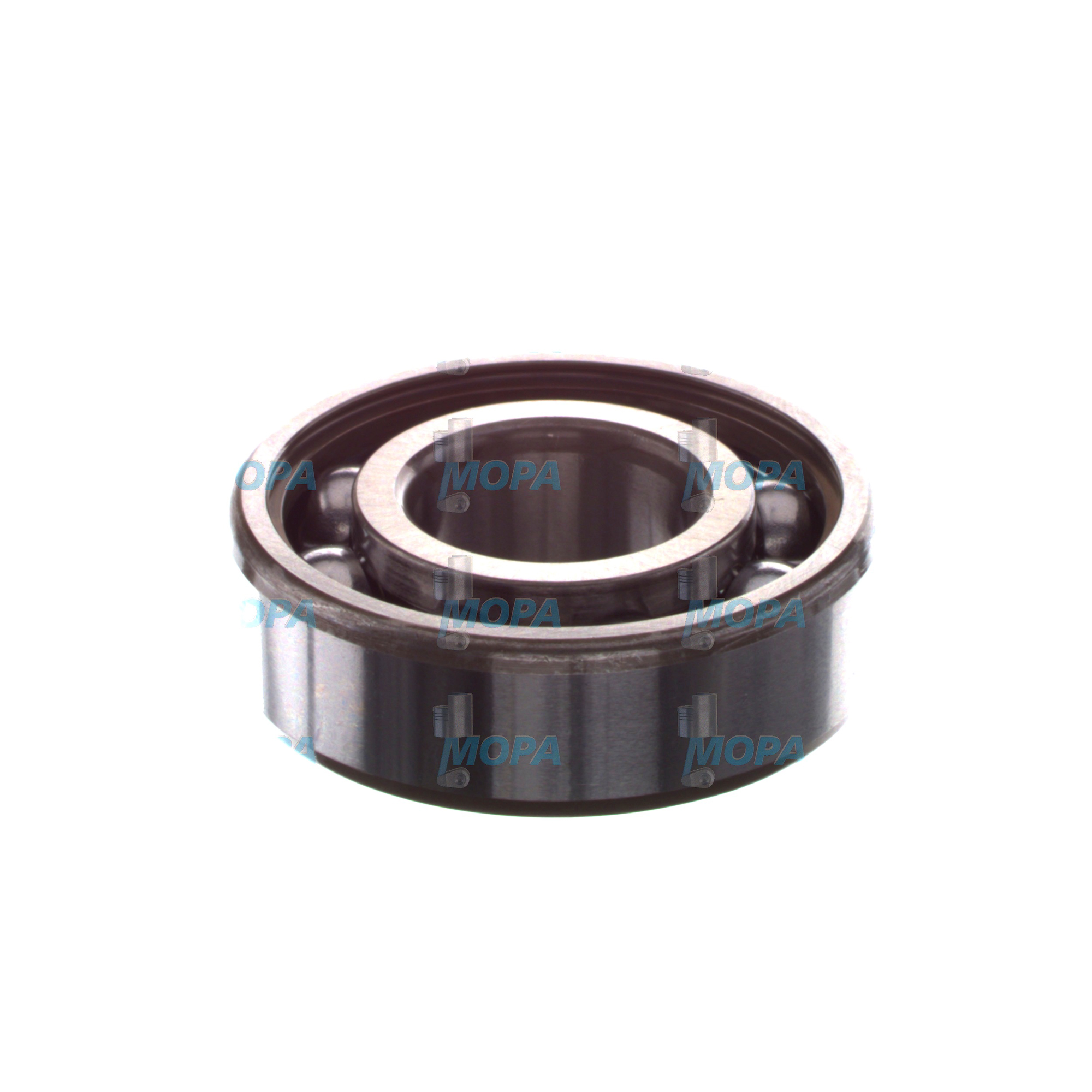

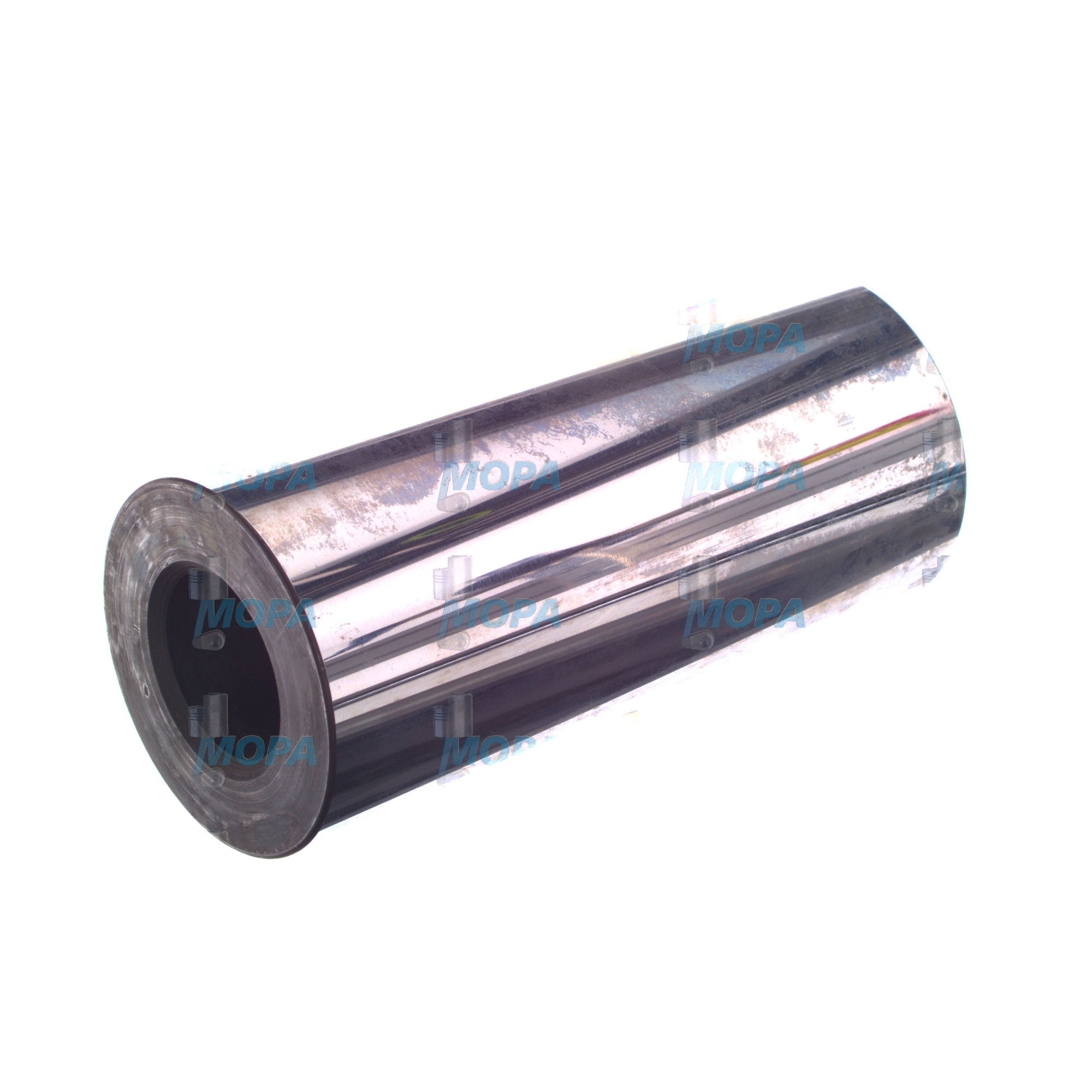

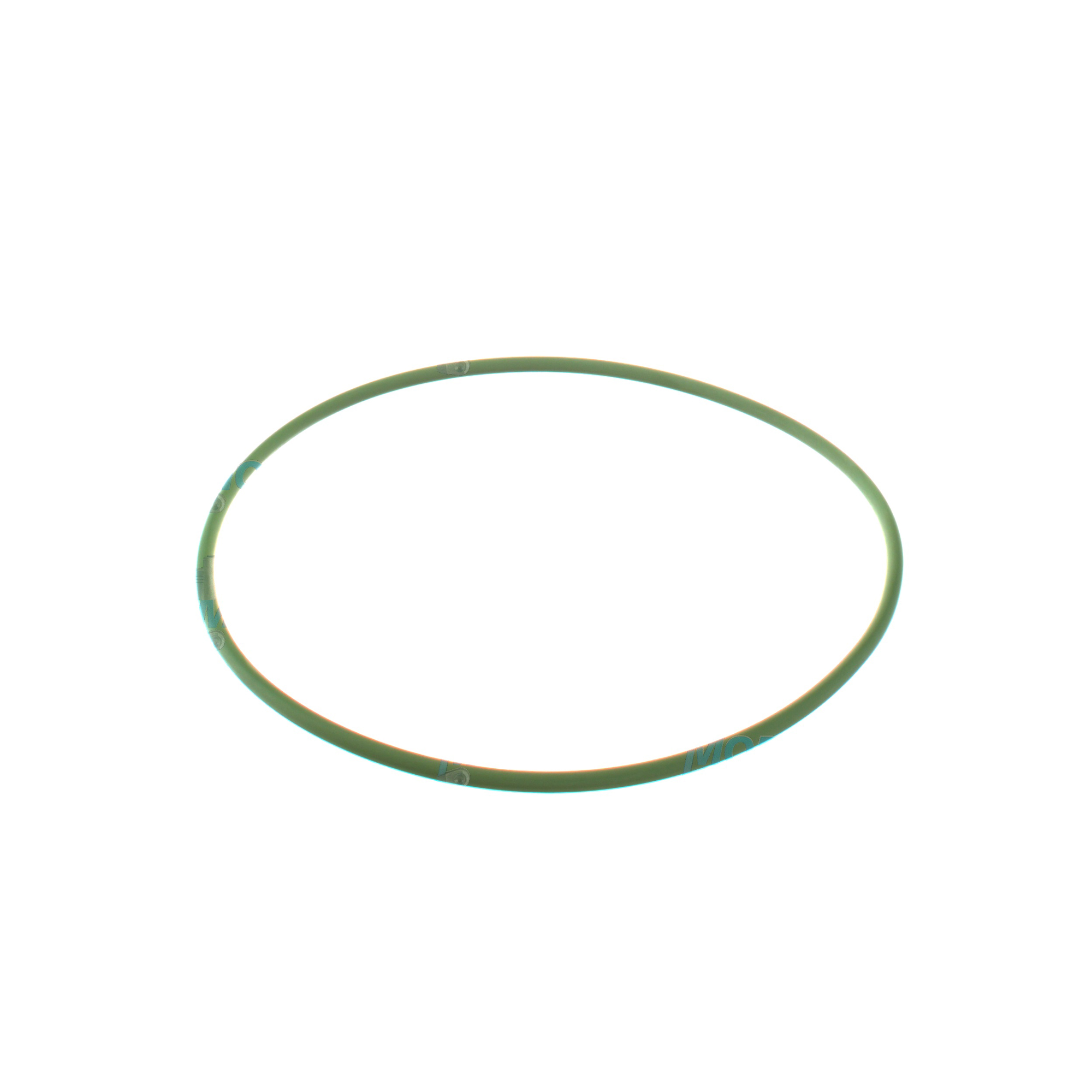

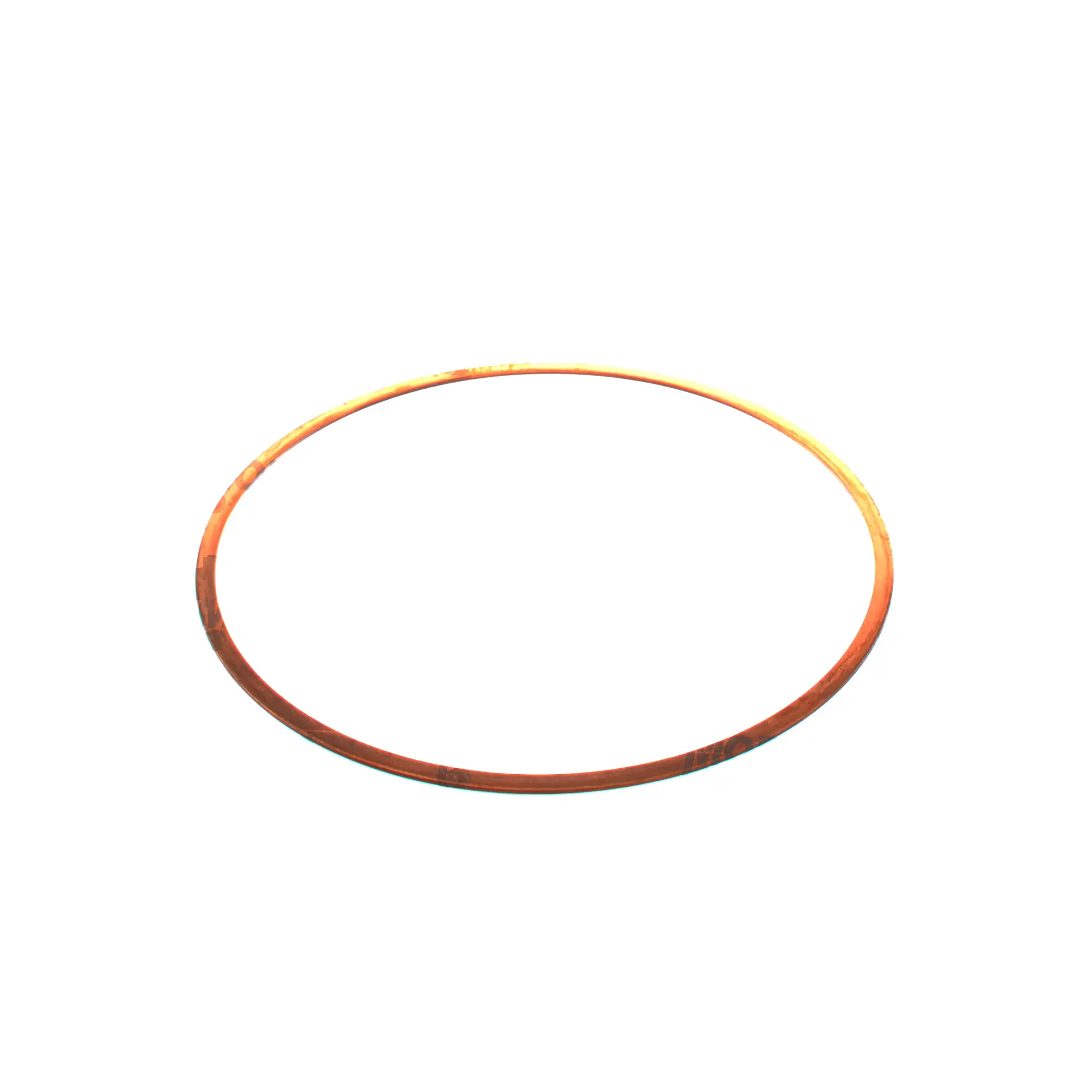

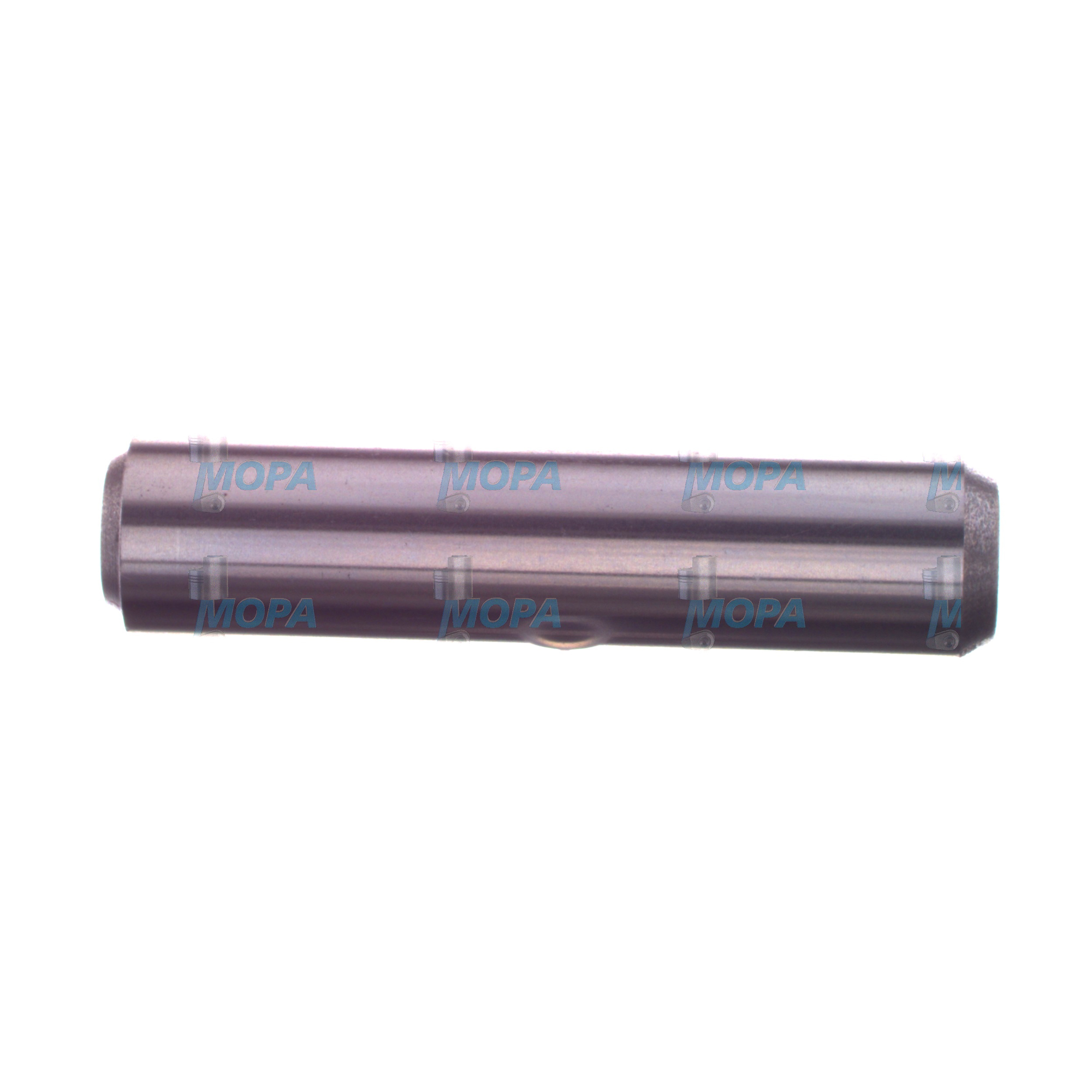

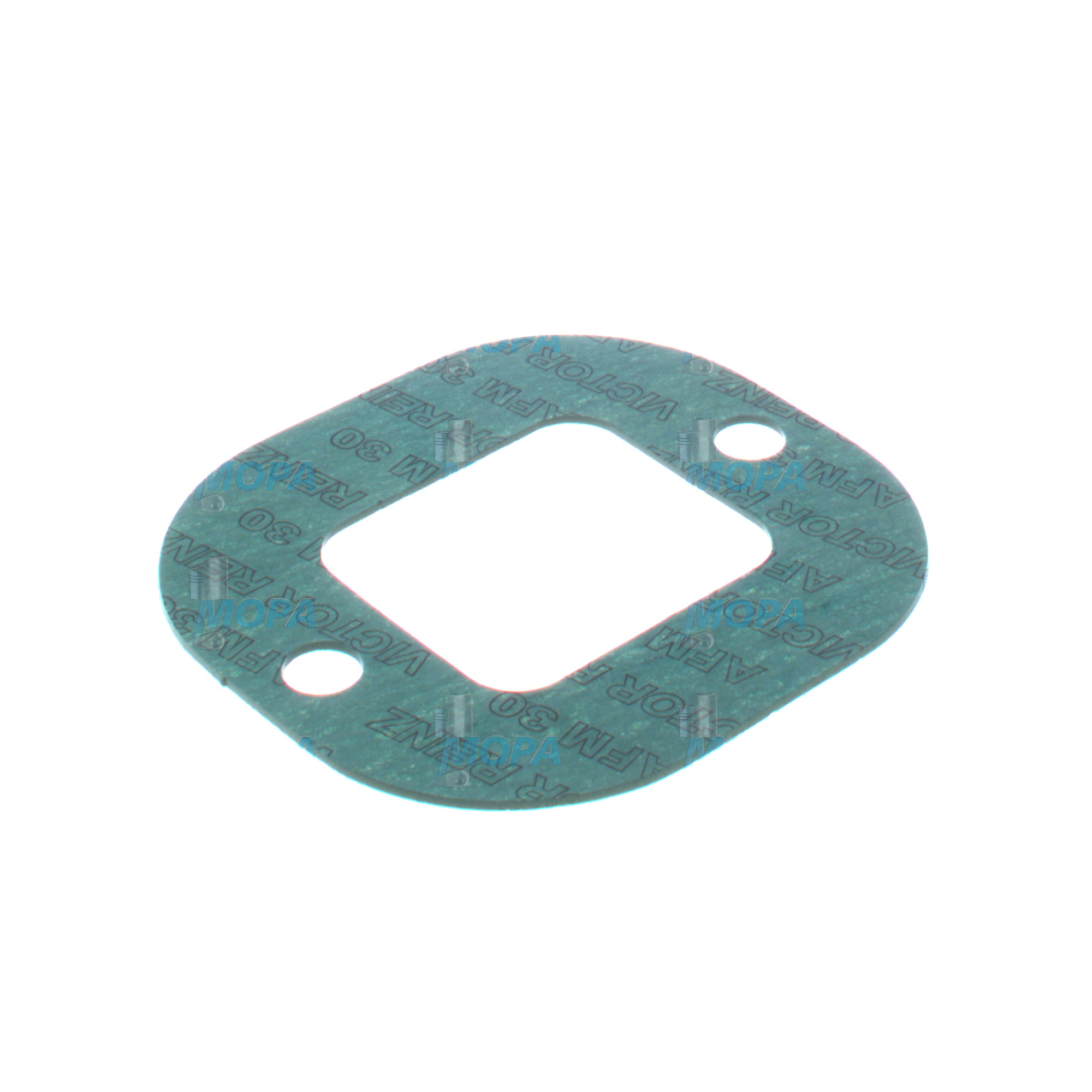

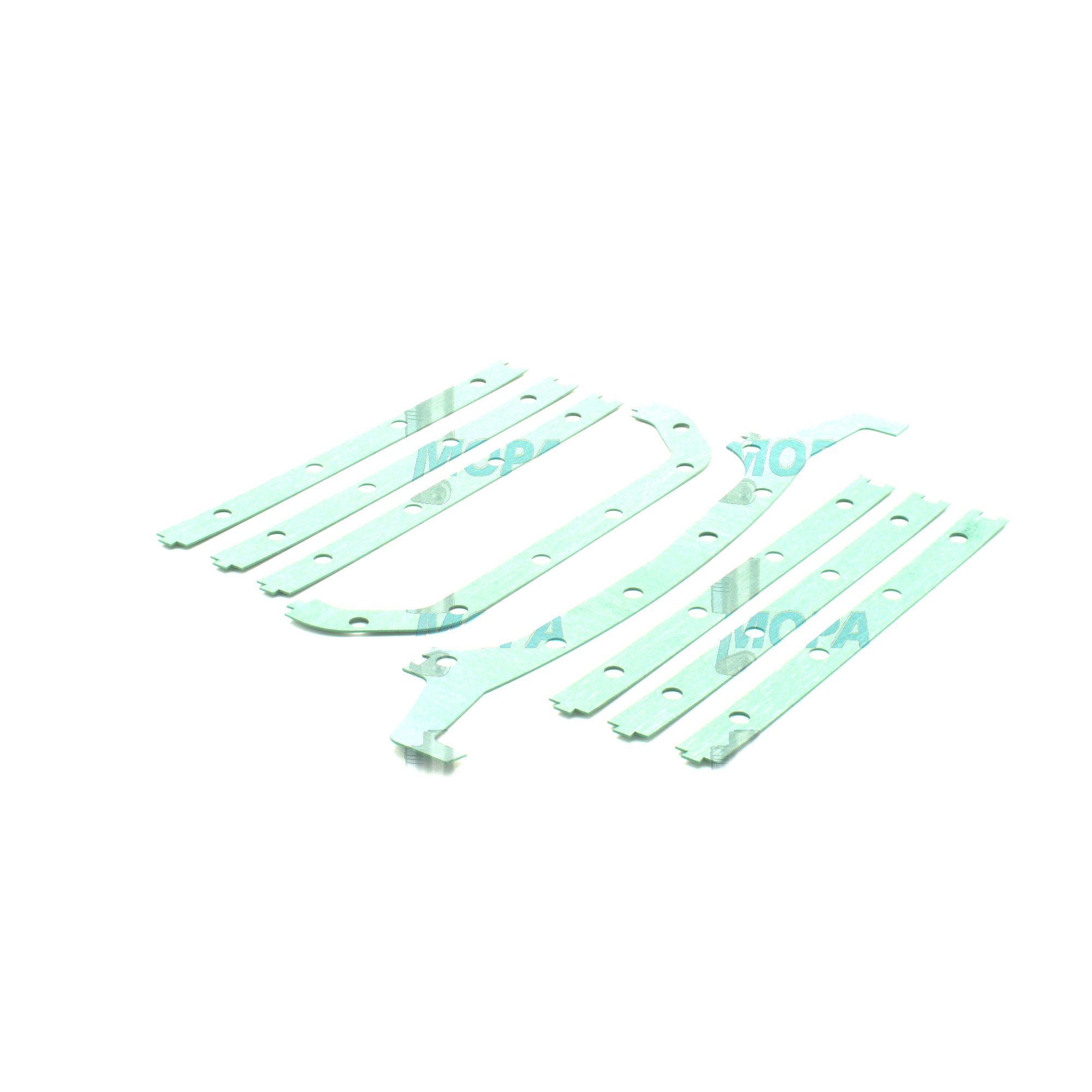

Using OEM spare parts suitable for F6M716 is pivotal to preserving the engine’s designed performance envelope. Precision-matched components—injectors, pumps, pistons, liners, valves, bearings, seals, and cooling system elements—must meet the same engineering specifications the engine was built around. When tolerances, materials, and treatments align with the engine’s original design intent, combustion efficiency remains stable, oil control is maintained, and thermal loads are properly managed.

Why choose OEM spare parts suitable for F6M716

With OEM spare parts suitable for F6M716, operators protect fuel efficiency, emission stability, and load acceptance. Calibrated fuel system parts sustain precise injection timing and atomization. Correct metallurgy and surface treatments on wear components safeguard the cranktrain and cylinder set under continuous duty. Gaskets and seals rated for the engine’s temperature and pressure cycles help prevent coolant and lube leaks that erode reliability. In aggregate, these factors extend overhaul intervals and reduce downtime across propulsion and auxiliary applications.

MOPA is a reliable partner for OEM spare parts suitable for F6M716. From advisory support on correct part selection to timely supply for scheduled maintenance or urgent repairs, MOPA helps purchasing teams and chief engineers keep assets online. By aligning inventories with actual engine configurations—turbocharged vs. naturally aspirated variants, specific governor setups, and marine cooling adaptations—MOPA streamlines procurement and supports predictable maintenance windows.

Advantages of OEM spare parts suitable for F6M716

· Exact fit and tolerance control protect core components.

· Consistent combustion quality preserves power and fuel economy.

· Materials built for thermal and mechanical loads extend service life.

· Stable emissions and smooth load response in marine duty cycles.

· Reduced risk of unplanned downtime and repeat maintenance.

· Expert sourcing support from MOPA for fast, correct delivery.

Conclusion: F6M716 value and assured parts supply

The F6M716 stands out as a dependable, efficient, and easy-to-service six‑cylinder platform for marine and stationary applications, combining practical power density with a smooth torque curve and robust components. Its widespread use across fleets reflects a sound engineering balance that prioritizes uptime and lifecycle efficiency.

To preserve that performance, rely on OEM spare parts suitable for F6M716 and the expertise of MOPA. With the right parts and support, operators sustain reliability, efficiency, and long service life from every F6M716 in their fleet.