A6M816

A6M816 marine engine by MWM & Deutz

The A6M816 is a proven six-cylinder diesel engine that has earned a long-standing reputation for dependable performance in propulsion and auxiliary duties. While it belongs to the 816 series developed by MWM & Deutz, the focus here is on the A6M816 itself: a balanced combination of robust mechanical design, efficient combustion, and service-friendly construction. Operators value the A6M816 for its steady power delivery, low-vibration running, and predictable lifecycle costs across a broad range of marine and stationary applications.

A6M816 technical characteristics and performance data

The A6M816 is configured as an in-line, 6-cylinder, four-stroke diesel engine. Typical builds are turbocharged with charge-air cooling to stabilize air temperatures and improve specific output in both propulsion and auxiliary roles. The crankcase and cylinder block are engineered for rigidity, commonly using replaceable wet liners to simplify overhauls and extend the service life of the base engine. Fuel delivery is handled via a precision inline injection pump with robust mechanical governing; many fleets also use upgraded control packages for improved load response and monitoring.

In practical deployment, the A6M816 operates in the medium-speed range, with governed speeds commonly set between approximately 900 and 1,500 rpm depending on the duty profile. Power output for the A6M816 diesel engine typically spans the mid-hundreds of kilowatts, with application-specific ratings for propulsion or generator drive. Across the 816 family, a 6-cylinder configuration of this class is frequently found with a displacement in the high-teens to mid-twenties liters, which aligns with the engine’s characteristic torque curve and its ability to sustain continuous loads. The A6M816 works efficiently on marine distillate fuels (MGO/MDO) and is well-suited to classification-compliant installations when paired with appropriate auxiliaries and exhaust treatment.

Engineers appreciate the A6M816 marine engine for its straightforward mechanical layout, durable valve-train components, and a cooling and lubrication system optimized for long service intervals. The design supports accessible maintenance points—filters, pumps, and inspection covers are positioned to reduce service time, and the turbocharger and charge-air cooler can be serviced with standard workshop tooling. For shipowners aiming to strike the right balance between operational economy and reliability, the A6M816 has been a consistent choice.

A6M816 applications in marine and stationary duty

The A6M816 from the 816 series is widely used in coastal cargo vessels, inland cargo carriers, workboats, ferries, tug and offshore support units, and dredging equipment. As a genset prime mover, it is equally capable in shipboard auxiliary power, shore-based standby units, and continuous-duty power plants. The engine’s torque characteristics allow stable operation under variable loads—valuable for winches, pumps, and thrusters—while its medium-speed profile helps minimize noise and vibration in passenger and crew areas.

- · Six-cylinder in-line configuration. Compact footprint and balanced operation.

- · Four-stroke, turbocharged, and charge-air cooled. High efficiency in continuous duty.

- · Medium-speed operation (~900–1,500 rpm). Flexible for propulsion or genset roles.

- · Power in the mid-hundreds of kW. Configurable for different class notations and loads.

- · Durable wet-liner block design. Simplified overhauls and predictable service planning.

- · Reliable mechanical fuel system. Stable combustion and easy field service.

- · Suitable for marine distillate fuels. Clean running with consistent fuel economy.

- · Broad application range. Cargo, passenger, offshore, and stationary power.

Why operators value the A6M816 diesel engine

Beyond headline output, what sets the A6M816 apart is predictable uptime. Its mechanical systems are well-understood across global shipyards and engineering crews. Many fleets standardize on the A6M816 MWM & Deutz platform because it supports streamlined spare parts provisioning, straightforward troubleshooting, and long overhaul intervals when operated within recommended load and temperature envelopes. For buyers comparing propulsion choices, lifecycle cost modeling often favors the A6M816 due to its maintainability and the wide availability of A6M816 OEM parts.

OEM spare parts suitable for A6M816 — performance, reliability, service life

To protect performance and long-term reliability, specifying OEM spare parts suitable for A6M816 is essential. Precision-matched components—pistons, ring packs, liners, bearings, injector nozzles, and turbocharger cartridges—are built to the dimensional tolerances and materials the A6M816 was engineered around. That precision safeguards critical clearances, controls blow-by, stabilizes oil consumption, and preserves fuel injection timing and spray patterns. As a result, combustion remains clean, exhaust temperatures stay balanced across cylinders, and crankshaft and valve-train loads remain within the design envelope.

Using OEM spare parts suitable for A6M816 helps maintain class-compliant performance, supports consistent specific fuel consumption, and reduces unplanned downtime by avoiding compatibility issues. Sealing systems—gaskets, O-rings, and seals—made for the A6M816 resist thermal cycling and marine environmental stress, helping avoid coolant and oil cross-contamination. Likewise, charge-air cooler elements and filtration media specified for the engine protect against fouling and abrasive wear, extending service intervals for the turbocharger and cylinder assemblies.

MOPA is a reliable partner for OEM spare parts suitable for A6M816. From complete overhaul kits to individual service items, MOPA provides documented parts selection, batch traceability, and rapid logistics to minimize laytime. Technical support ensures that components such as fuel injection elements, valve-train parts, and rotating assemblies are matched to your rating and duty profile. Whether you need A6M816 MWM & Deutz diesel engine components for propulsion or auxiliary applications, MOPA’s supply capability helps keep your asset performing to specification.

What you gain with OEM spare parts suitable for A6M816

- · Maintained output and efficiency. Preserve rated power and fuel economy.

- · Stable combustion quality. Consistent injector and nozzle performance.

- · Controlled wear rates. Correct metallurgy and surface finishes.

- · Lower downtime risk. High fit accuracy reduces rework.

- · Longer service intervals. Durable sealing and filtration elements.

- · Clean emissions profile. Balanced cylinder temperatures and timing.

- · Streamlined maintenance. Parts designed for the A6M816 fit and tooling.

- · Trusted supply partner. MOPA supports fast, accurate delivery.

Conclusion: A6M816 value and assured parts supply

The A6M816 combines a durable six-cylinder architecture with medium-speed efficiency, making it a dependable choice for propulsion and auxiliary power across shipping and stationary installations. Its practical design, serviceability, and balanced performance explain why technical decision-makers continue to specify this engine.

To sustain that performance over the long term, rely on OEM spare parts suitable for A6M816. MOPA supplies the components and support needed to keep your A6M816 operating safely, efficiently, and in line with the expectations of fleet managers and shipowners.

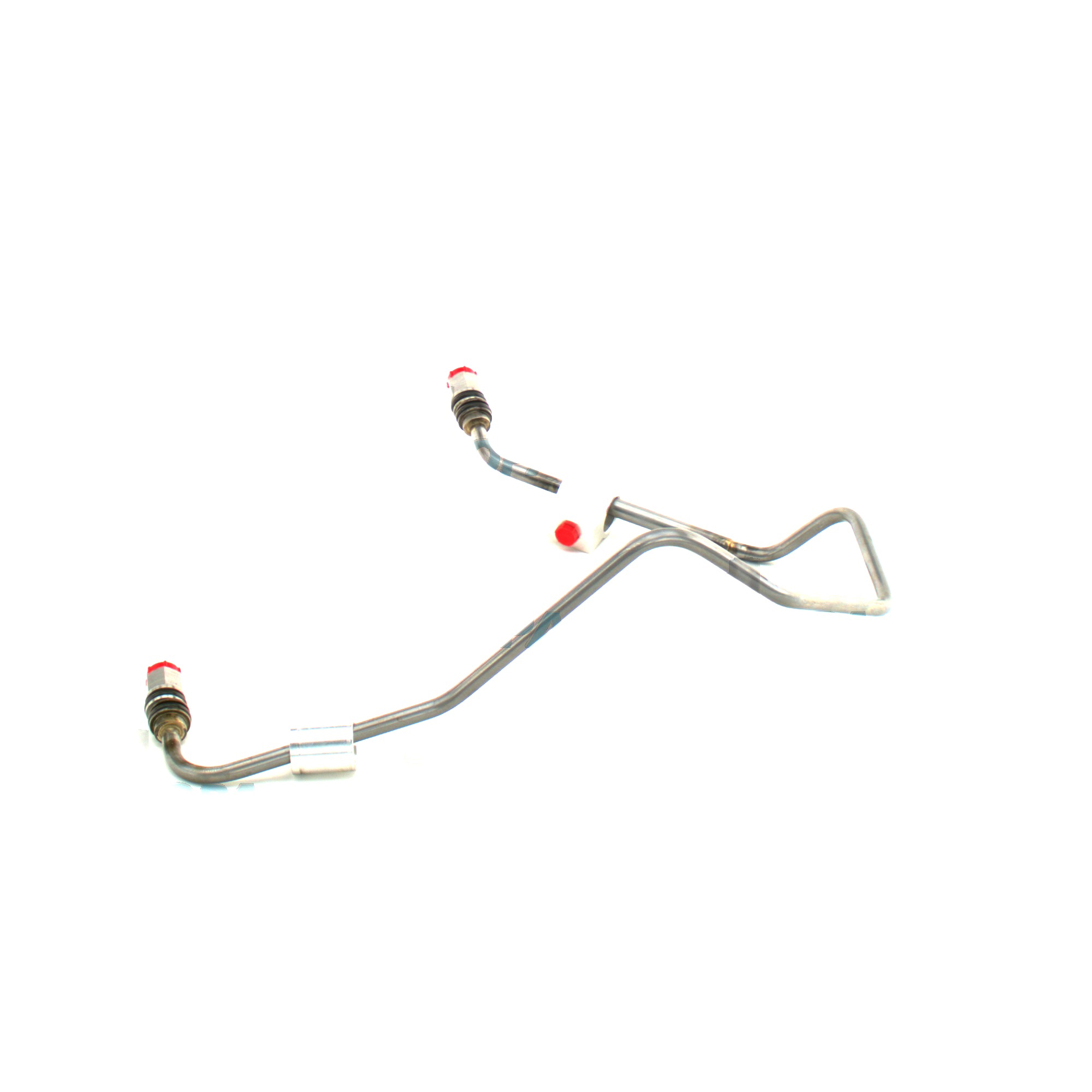

HIGH PRESSURE PIPE with the comparison number 04002658 suitable for MWM & Deutz engines

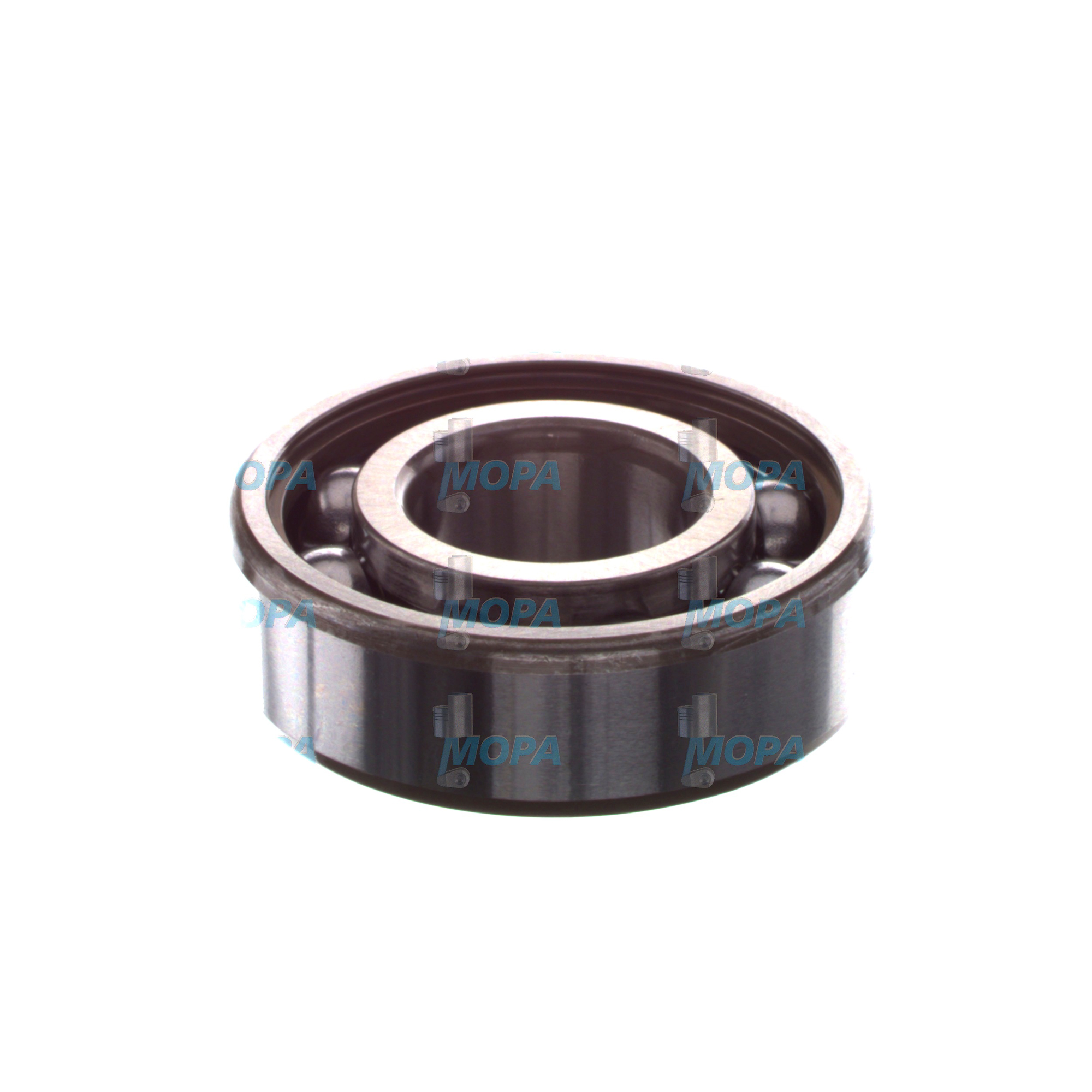

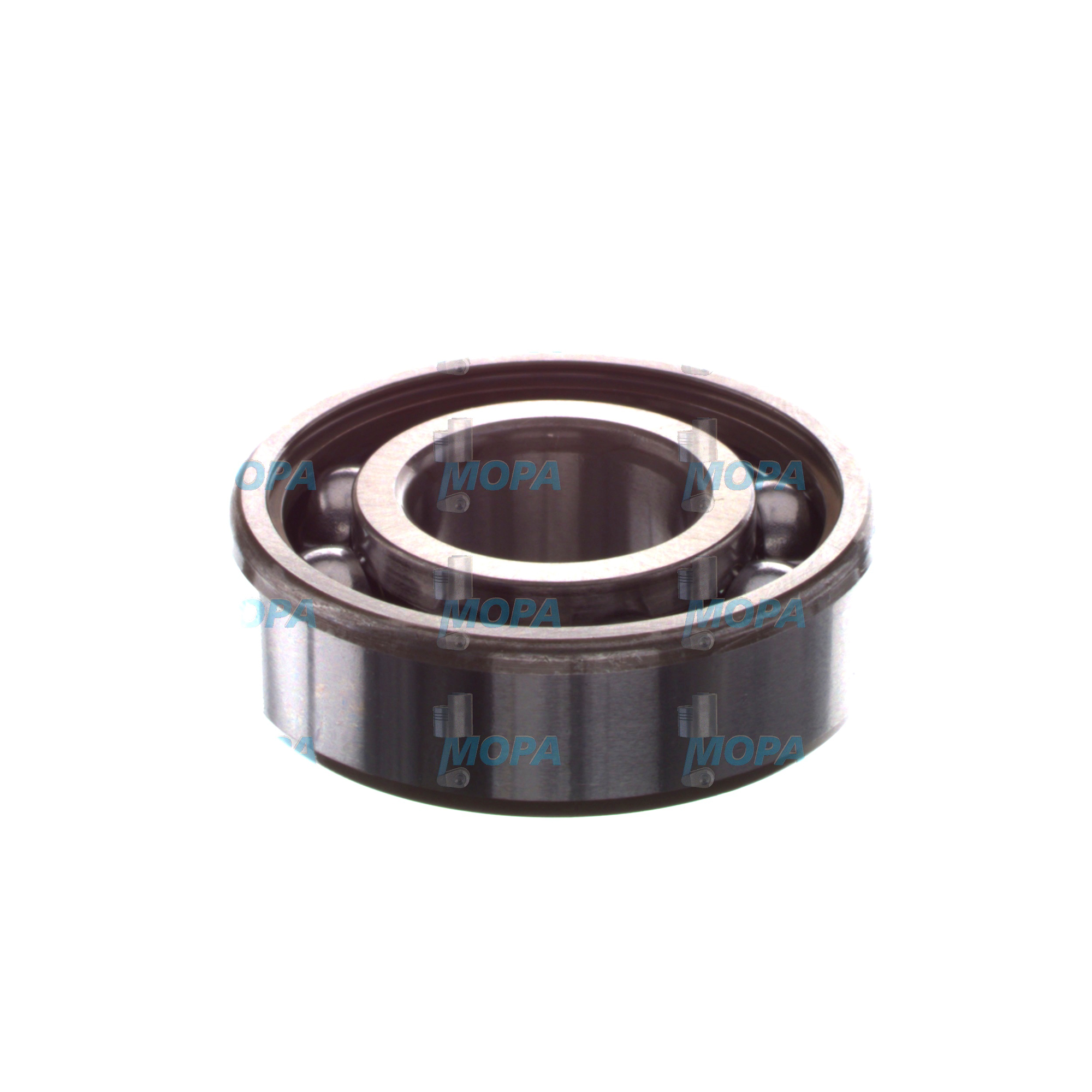

Grooved ball bearing suitable for MWM & Deutz engines The grooved ball bearing with the comparison number 603200456204 is the perfect solution for all your spare parts needs. This bearing model is suitable for MWM & Deutz engines and has been specifically designed for the series 816 as well as the engine types A6M816, BA6M816, BAM816, and SBA12M816. By using OEM spare parts, you receive a product that meets high quality standards and meets the requirements of your engines.

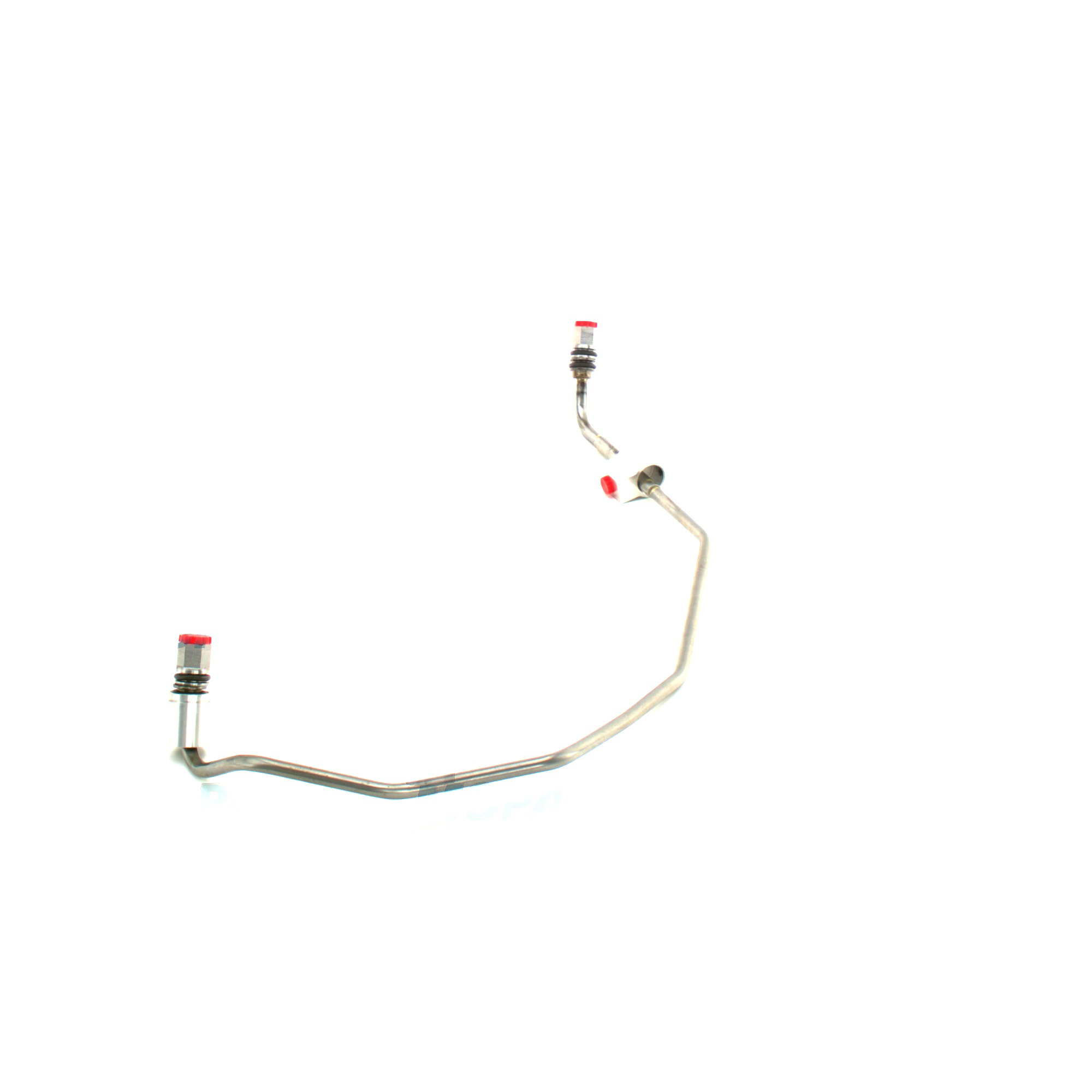

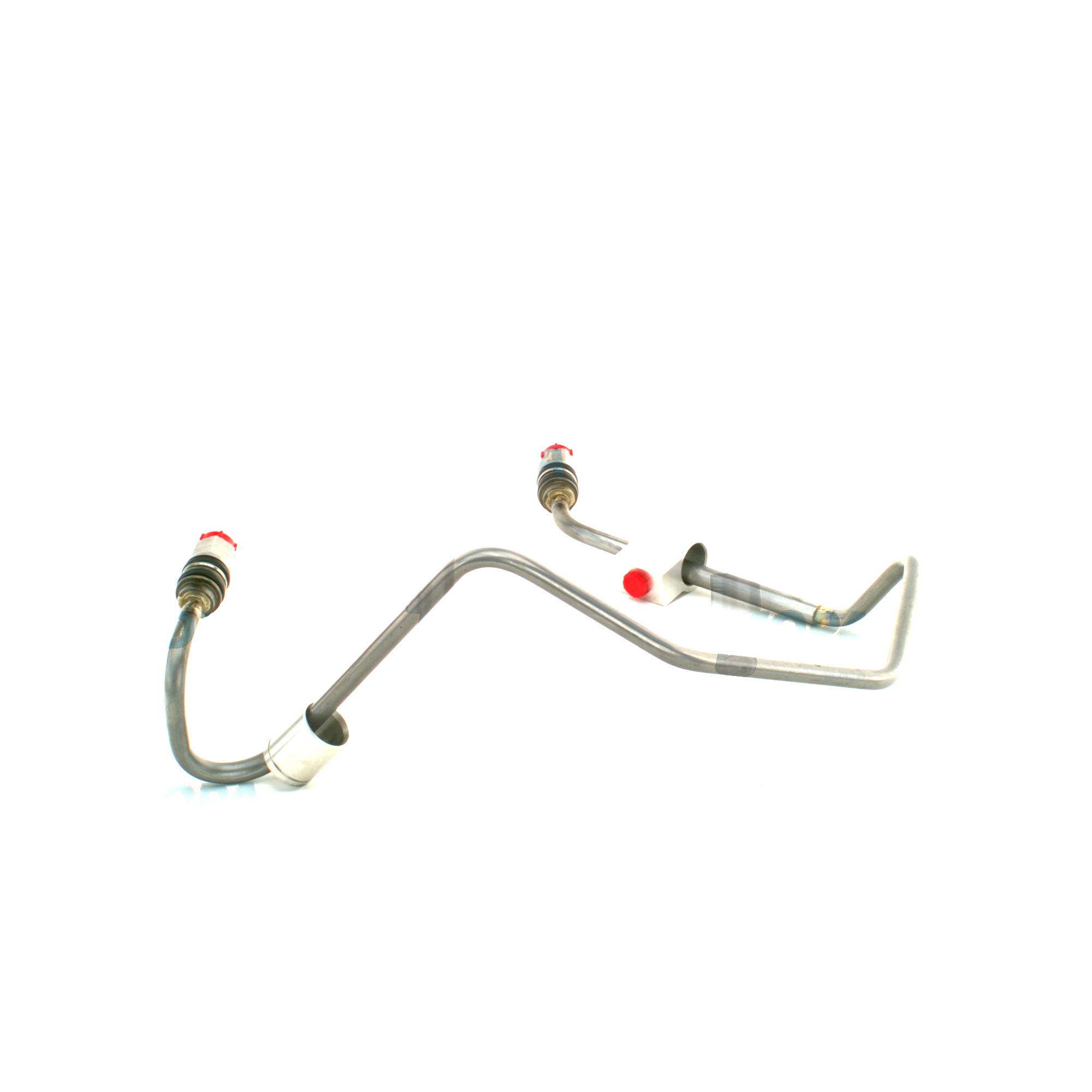

High Pressure Pipe suitable for MWM & Deutz enginesThe high pressure pipe with the comparison number 04002657 is an indispensable OEM replacement part optimized for efficient performance of engines in demanding environments. This powerful product belongs to the category "Lines and pipes" and offers precise functionality specifically tailored to the requirements of the series 816. This high pressure pipe is suitable for engines of the type A6M816 and BA6M816, making it ideal for companies that prioritize quality and efficiency.Robust Features of the High Pressure PipeWeighing 0.618 kg and featuring compact dimensions of 63.8 cm in length and width, as well as a height of 8.2 cm, the high pressure pipe not only impresses with its optimal fit but also ensures a smooth fuel flow. This robustness is crucial for the reliable operation of MWM & Deutz engines, especially under intense use in marine and stationary applications. The quality of the OEM replacement part significantly contributes to promoting effective engine performance.

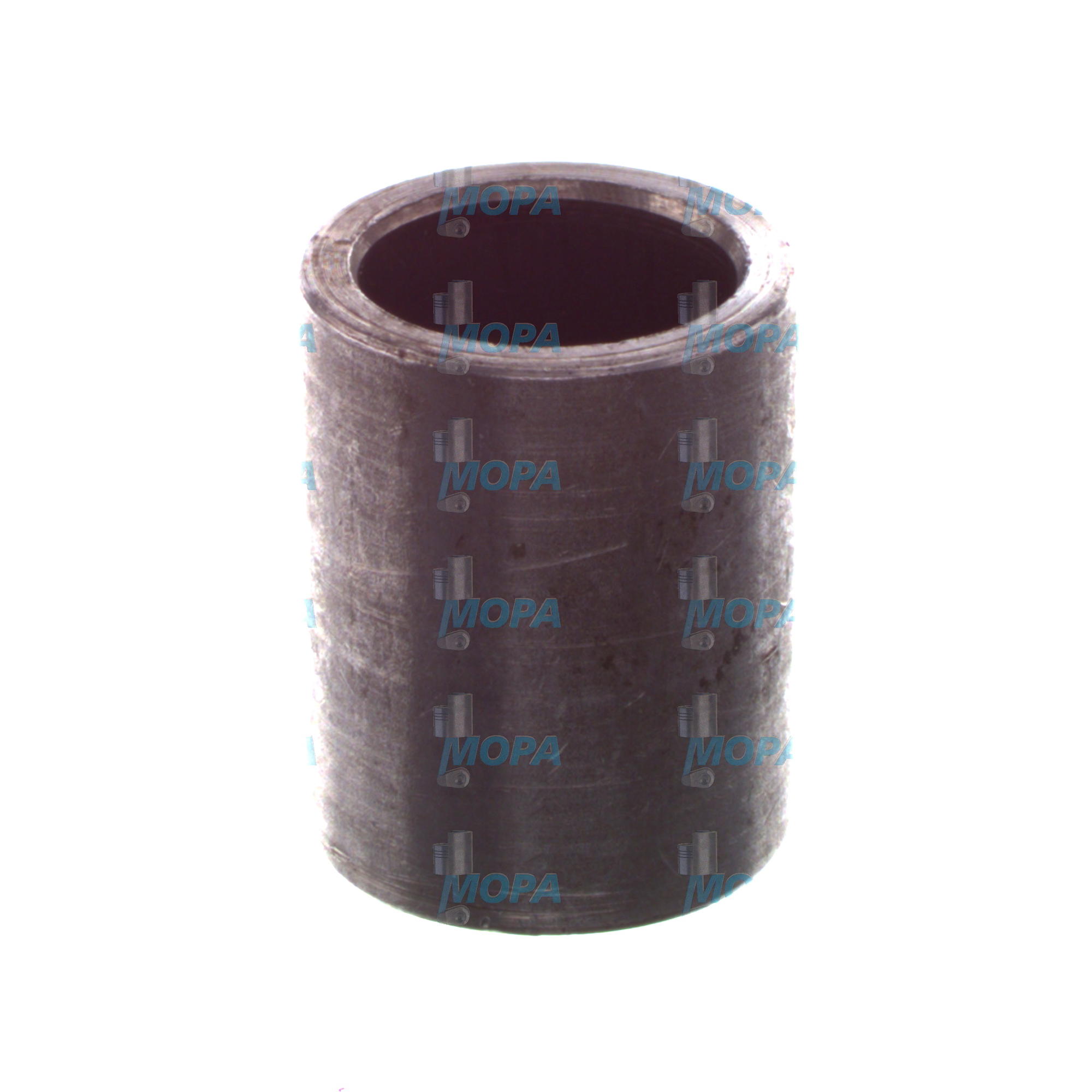

Bush compatible with MWM & Deutz enginesDiscover the bush with the part number 03374198, designed for the optimal functionality of your MWM & Deutz engines. As an essential component of the connecting elements, this bush ensures that your diesel and gas engines operate reliably. The product is characterized by precise dimensions and a perfect fit that meets the specific requirements of these engines.

Certified OEM Spare Part – Shaft for MWM & DeutzDiscover our OEM spare part, the shaft (comparison number: 03374196), which is ideally suited to support your needs in engine maintenance. This product is essential for all organizations that require reliable spare parts for their compatible with MWM & Deutz engines. The comparison number 03374196 indicates a precise match with specific compatible with MWM & Deutz applications, while the spare part remains relevant for various models and engine types.Technical Data of the ShaftThe shaft weighs a lightweight 0.357 kg and has dimensions of 16.8 cm in length and width, as well as 2.5 cm in height. Due to this efficiency, the shaft designed for compatible with MWM & Deutz is able to provide excellent performance characteristics. Rely on our products to achieve precise integration into your existing systems.

Essential Rotary Shaft Lip Seal 358/110/130 for EnginesDiscover the rotary shaft lip seal with the comparison number 358/110/130 – an essential product that offers optimal protection for your Deutz engines. The rotary shaft lip seal effectively prevents oil seepage, thus supporting the smooth operation of your machines. Specifically designed to meet the high standards of the industry, this OEM spare part is indispensable for anyone who values performance and durability.

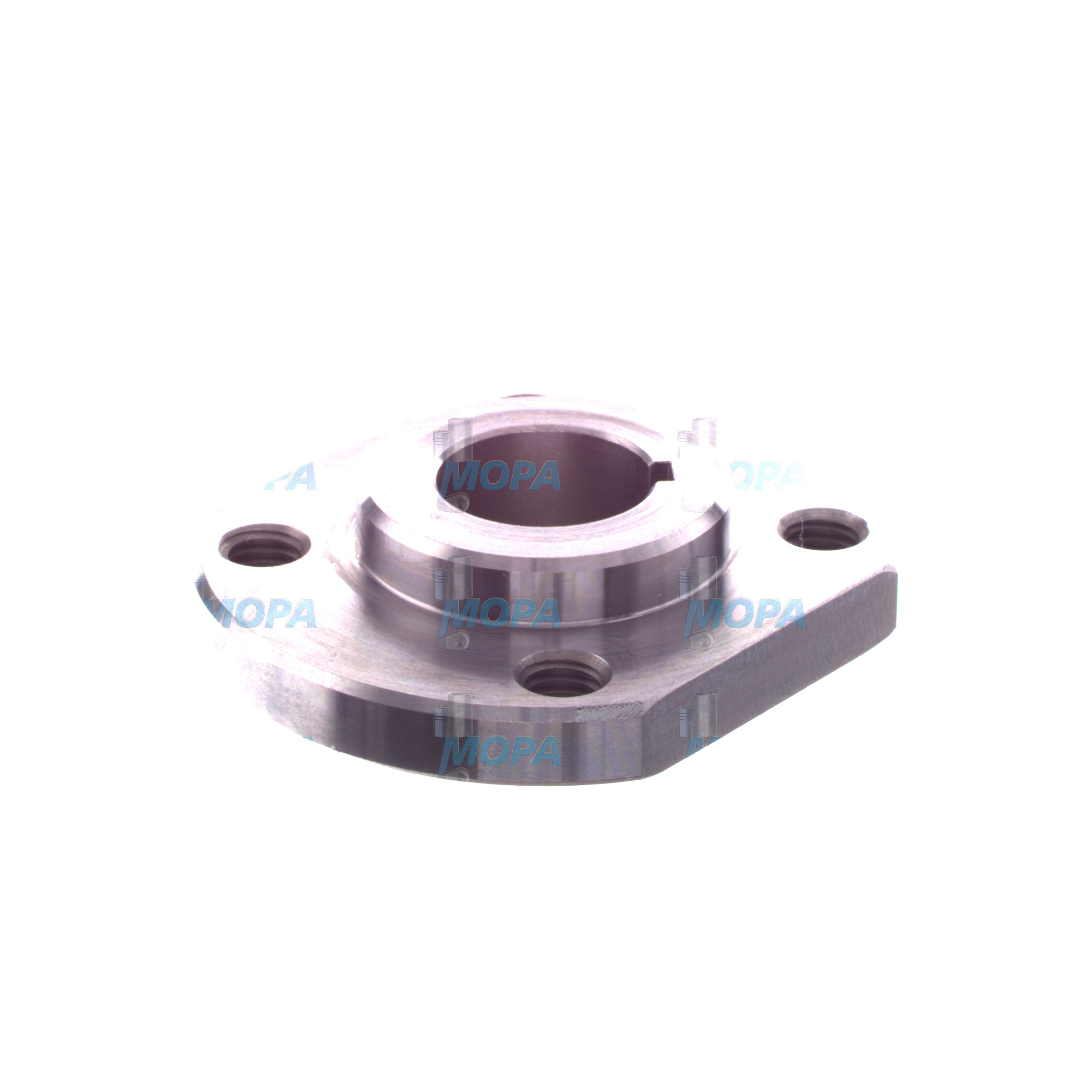

First-Class Flange Compatible with MWM & Deutz EnginesDiscover the functionality and reliability of the flange with the comparison number 02157193. This product is an essential replacement part, compatible with the MWM & Deutz engines of series 816. The quality of these OEM replacement parts ensures precise fit and is designed for optimal performance in your engine system. Rely on years of expertise in the selection and provision of these essential components.

Injection line suitable for MWM & Deutz enginesDiscover the injection line suitable for MWM & Deutz engines, particularly for the series 816 as well as the engine types A6M816 and BA6M816. With the comparison number 04002656, you receive a product that is optimally tailored to the requirements of your technical equipment. This injection line not only ensures efficient fuel supply but also contributes to the performance of your engine.

Grooved Ball Bearing - Efficient OEM Replacement PartThe grooved ball bearing with the comparison number 358/127/180 is an essential OEM replacement part for anyone relying on efficiency and reliability in engines. This product impresses with its excellent construction and is specifically designed to meet the demands of the entire series 816. This quality makes the grooved ball bearing the first choice for professionals using replacement parts for high-performance machines.Optimal Fit for MWM & Deutz EnginesThe grooved ball bearing is suitable for MWM & Deutz engines and enables flawless function in numerous applications. Specifically designed for compatibility with engine types A6M816, BA6M816, BAM816, and SBA12M816, this component ensures that engines can operate optimally. With a weight of only 0.104 kg and compact dimensions of 4.7 cm in length and width, as well as 1.4 cm in height, it offers flexibility and efficiency for various usage possibilities.

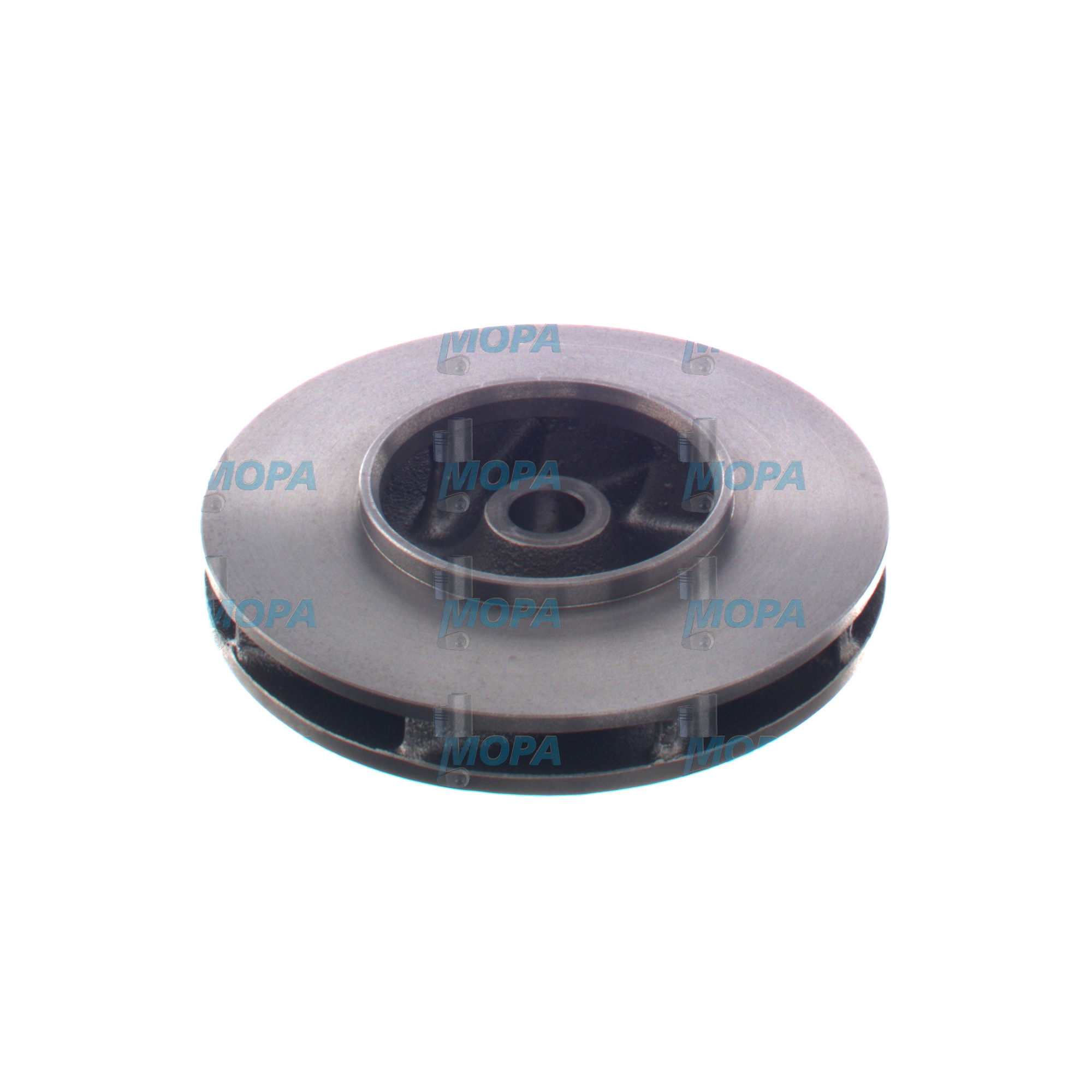

Discover the impeller with comparison number 04005557Discover our impeller with the comparison number 04005557, a premium product specifically designed to meet the demands of your MWM & Deutz engines. This OEM spare part belongs to the category "Pumps, parts and accessories" and is suitable for the model series 816 as well as the engine types A6M816, BA12M816, BA6M816, and BAM816.

High pressure pipe 04002654 for reliable applicationsThe high pressure pipe with the comparison number 04002654 is an essential product specifically designed to integrate optimally into your machines. This crucial component is suitable for MWM & Deutz engines and ensures efficient operation, significantly enhancing the performance of your systems. Weighing 0.622 kg and measuring 34.1 cm x 34.1 cm x 13.9 cm, this high pressure pipe meets high standards and demanding requirements.Quality of OEM replacement partsOur high pressure pipe is a top-tier OEM replacement part, designed for the series 816 as well as engine types A6M816 and BA6M816. You benefit from the proven reliability of OEM replacement parts, which are specifically designed to secure the performance and lifespan of your engines. This high pressure pipe can be easily integrated into existing systems and greatly optimizes the efficiency of your machines.

Premium Bush – Comparison Number 03374199 in DetailDiscover the Bush with the Comparison Number 03374199, a premium product that meets all quality and performance requirements. This OEM spare part is specifically designed for use in suitable for MWM & Deutz engines and ensures optimal functionality in your machines. The bush is an essential component in connecting elements and offers excellent performance necessary for various applications.Technical Details: Suitable for Engines with Optimal FitThe thoughtful dimensions of the bush are reflected in its compact measurements of 2.7 cm in length and width and a height of 1.3 cm. Weighing only 0.033 kg, this OEM spare part is ideal for engines that require precise fitting. Suitable for series 816 and engine type A6M816, this bush provides the necessary stability and reliability for marine and stationary applications.

Quality of the Rotary Shaft Lip Seal with Comparison Number 358/135/41Discover our product, the rotary shaft lip seal with comparison number 358/135/41. This premium OEM replacement part is essential for the efficient operation of your engines. The rotary shaft lip seal ensures crucial sealing, which is particularly important for products that heavily rely on efficient mechanisms. Our replacement parts meet the high standards you expect from a manufacturer and set benchmarks in the industry.Compatibility for Deutz EnginesOur rotary shaft lip seal with comparison number 358/135/41 is compatible with the Deutz series 816 as well as engine types A6M816, BA12M816, BA6M816, and BAM816. With compact dimensions of 4.2 cm in length and width and a height of 1 cm, this product offers an optimal solution for maintaining the functionality of your machines. Weighing only 0.015 kg, it also facilitates the installation process.

Reliable Cooling Water Pump Recondit. OverviewThe Cooling water pump recondit. with the comparison number 04005689RECON is an essential product specifically designed for the maintenance of suitable for MWM & Deutz engines. Ideal for ensuring the proper cooling of your engines, this OEM replacement part offers durable performance and quality that matches the original.Characteristics of the Replacement Part Suitable for MWM & DeutzThe OEM replacement part is suitable for the series 816 and allows for maximum efficiency and reliability. Engines that depend on this model series find the ideal partner in the cooling water pump. Weighing 13.4 kg, it impresses with its robust characteristics and is optimally tailored to the requirements in marine and stationary operations.

Injection line for optimal engine performanceThe injection line with the comparison number 04002655 is the ideal OEM replacement part for your engines. This product offers outstanding performance and durability, making it an indispensable component in industrial applications. Trust in the quality of our OEM replacement parts and benefit from their efficiency.

Precise Fit with Comparison Number 04002653Discover the High pressure pipe with the comparison number 04002653 – an indispensable product that offers you outstanding performance. This OEM spare part is compatible with renowned manufacturers such as MWM & Deutz and ensures exact alignment with Series 816. Rely on quality and a reliable solution for your engines.Technical Details for Your NeedsWith a length of 40.5 cm, a width of 40.5 cm, and a height of 13.9 cm, the High pressure pipe is designed to provide optimal space in engine construction. Weighing 0.622 kg, this OEM spare part is your top choice when it comes to engines from MWM & Deutz. Compatible with selected engine types, such as A6M816 and BA6M816, this spare part ensures success in operation.

Innovative Non-return Valve for Your EnginesDiscover our non-return valve with the comparison number 04004432. This product is an essential OEM spare part that offers excellent performance when repairing or replacing parts for MWM & Deutz engines. Weighing only 0.055 kg, the non-return valve is both lightweight and robust, playing a crucial role in the efficiency of your engines.