BA16M816 diesel engine for demanding marine and power applications

The BA16M816 is the standout engine type in the renowned 816 series, engineered for long-running reliability and high specific output. Developed in the heritage of MWM & Deutz, this V16 unit is chosen by operators who require robust performance, predictable lifecycle costs, and a service-friendly design. While the 816 platform is well known across the industry, the BA16M816 commands attention for its balanced power-to-weight ratio, stable operation under fluctuating loads, and compatibility with a wide range of marine and stationary configurations.

BA16M816 technical characteristics and design

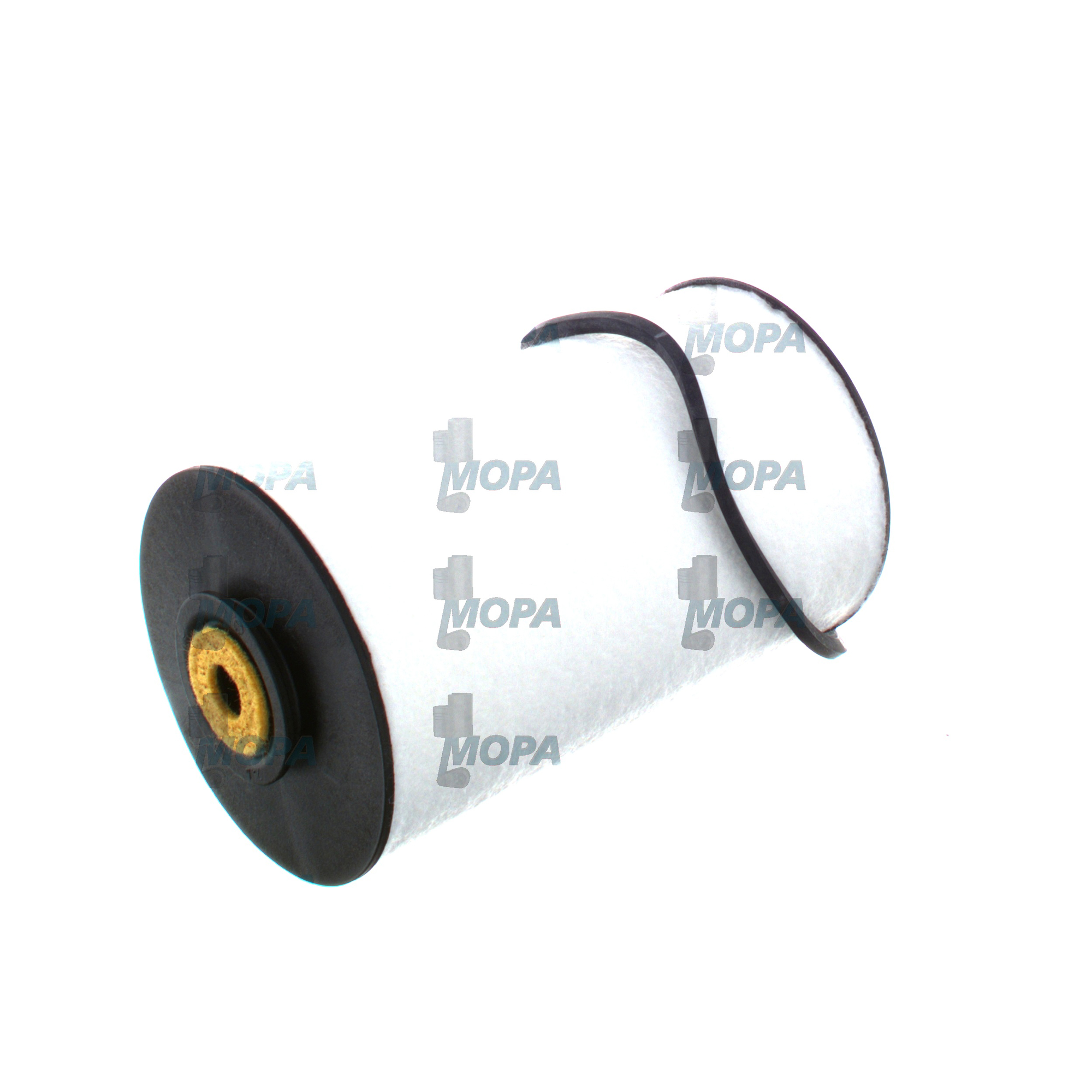

The BA16M816 is a four-stroke, turbocharged and charge‑air‑cooled V16 diesel engine designed to deliver dependable power in continuous and prime duty. Its architecture emphasizes mechanical simplicity combined with proven subsystems that facilitate maintenance in the engine room or at remote power sites. The BA16M816 diesel engine is commonly supplied with a robust crankcase, high-strength connecting rods, and a resilient valve train designed for extended service intervals. Fuel injection is configured for efficient atomization and consistent combustion, contributing to reliable starts and clean running, even with varying fuel qualities within marine distillate grades.

Depending on build and rating, the BA16M816 typically operates in the medium‑speed range, with nominal speeds often between approximately 600 and 1,000 rpm. Power output configurations cover a broad envelope suitable for propulsion and auxiliary generation, frequently positioned in the low‑ to mid‑megawatt class. Total displacement is in the high double‑digit liter range, with a strong torque profile that supports acceleration under load and steady-state efficiency. Cooling is handled through jacket‑water circuits and charge‑air cooling, while lubrication relies on a high-capacity, full‑flow filtration system to protect bearings and cylinder components in continuous duty.

For shipboard use, the BA16M816 marine engine can be direct‑coupled for propulsion or paired with reduction gearing for optimized propeller speeds. In auxiliary roles, it is commonly coupled to marine alternators sized for hotel loads, cargo handling, DP systems, or reefer power. In stationary applications, the BA16M816 by MWM & Deutz can be configured for base‑load or peak‑load generation, supporting island grids, industrial facilities, or emergency backup. Control options range from traditional mechanical governing to electronic assistance for tighter load‑sharing and emissions management, and the platform integrates well with SCR or oxidation catalysts when compliance strategies are required.

- · 16-cylinder V-configuration, four-stroke, turbocharged and charge‑air cooled.

- · Medium-speed operation, typically ~600–1,000 rpm depending on rating.

- · Power ratings in the low- to mid‑MW class for propulsion and genset duties.

- · Strong torque curve for transient load steps and harbor maneuvers.

- · Durable crankcase and valve train engineered for long service intervals.

- · Efficient fuel injection for stable combustion and reduced fuel consumption.

- · Flexible integration: propulsion, auxiliary generation, and stationary power.

- · Service-friendly layout with excellent access to wear components.

Why operators value the BA16M816 marine engine

Owners and technical managers choose the BA16M816 because it strikes a practical balance between output, fuel efficiency, and maintainability. The engine’s cylinder configuration delivers smooth running with low vibration levels for its class, benefiting hull comfort and generator set stability. Its component accessibility reduces time on task for inspections, injector servicing, and valve adjustments—key factors for vessels with tight schedules or remote power installations.

Typical applications include:

BA16M816 in maritime and stationary service

As a propulsion unit, the BA16M816 marine engine is frequently installed in cargo vessels, inland tankers, ferries, dredgers, and offshore support vessels where medium-speed characteristics and predictable fuel burn matter. In auxiliary roles, the BA16M816 diesel engine provides electrical power for reefer operations, hotel loads, DP thrusters, and deck machinery. On land, it is a reliable choice for industrial power plants, islanded microgrids, and critical backup systems. Thanks to its steady-state efficiency and robust design, the BA16M816 by MWM & Deutz maintains high availability and straightforward lifecycle planning.

Lifecycle performance and maintainability of the BA16M816 by MWM & Deutz

The BA16M816 platform supports long component lives when operated within recommended load factors and with high-quality fluids and filtration. Cylinder liners, pistons, and valve gear are engineered to predictable intervals, enabling planned overhauls that minimize downtime. With appropriate monitoring—oil analysis, exhaust temperatures, and charge‑air parameters—the engine provides early indicators that help chief engineers and plant supervisors act preventively. In multi‑engine plants, the BA16M816 responds well to load‑sharing strategies, reducing fuel consumption per kWh and distributing hours evenly across the fleet.

OEM spare parts suitable for BA16M816

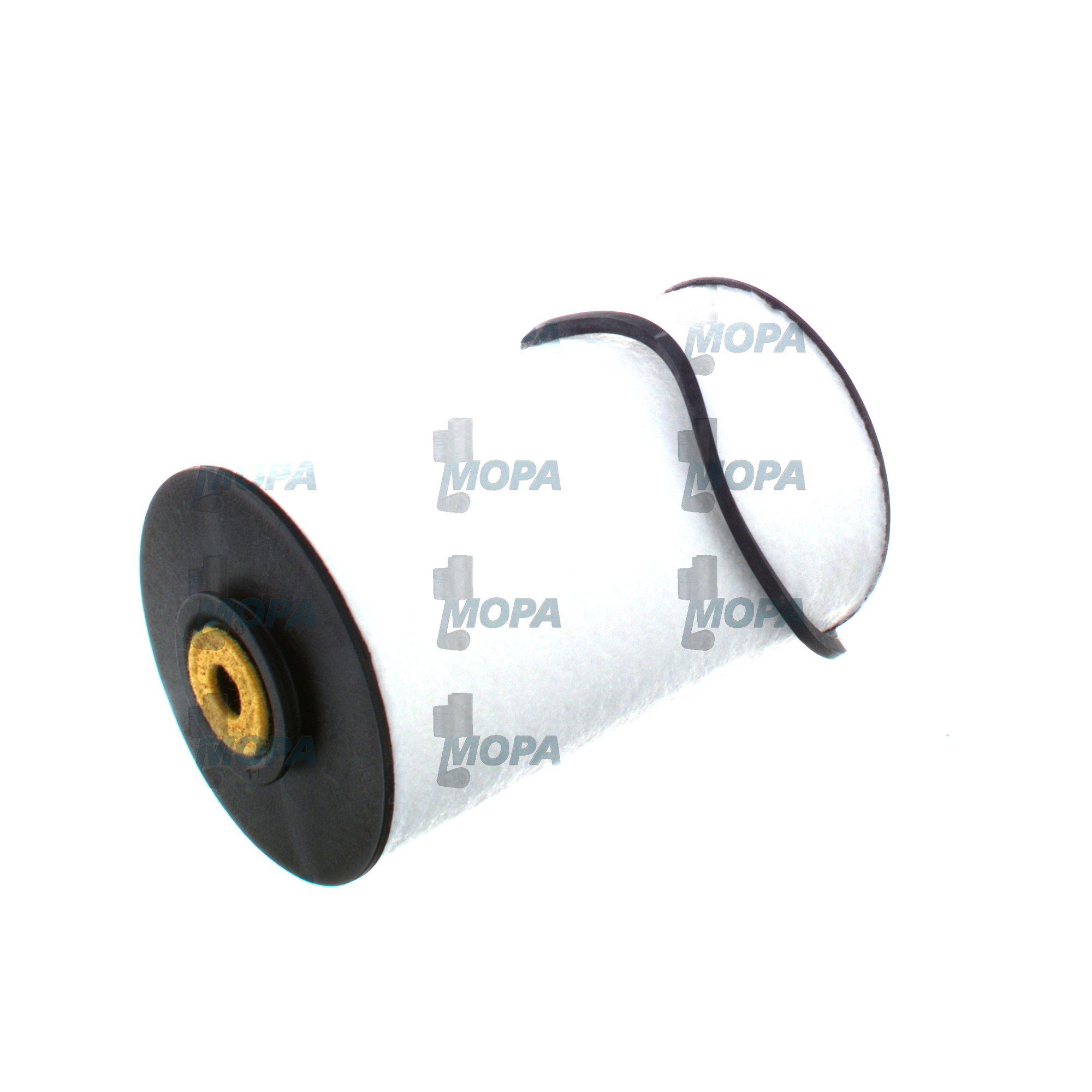

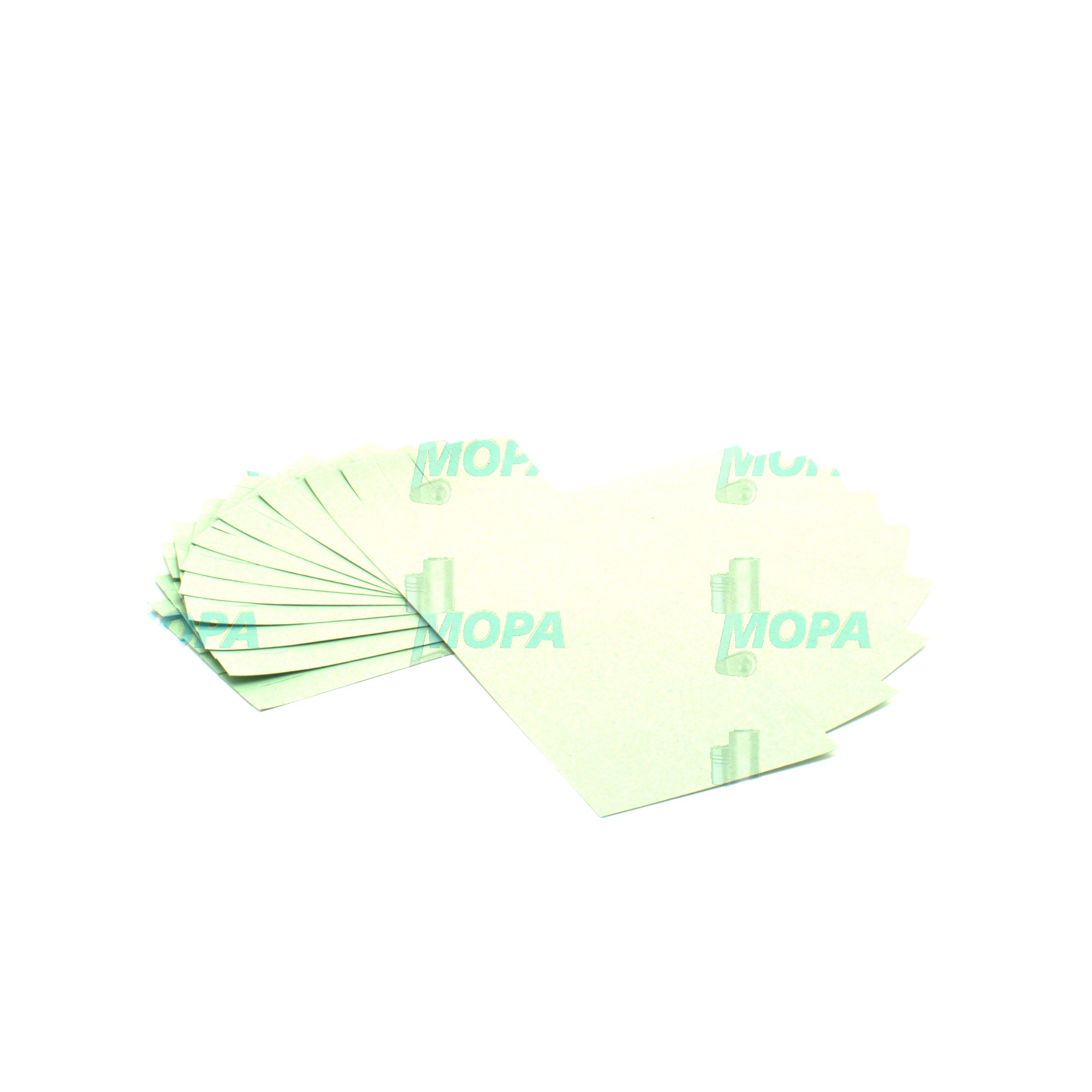

To sustain performance and protect the engine’s operating margins, OEM spare parts suitable for BA16M816 are essential. Precision‑matched pistons, rings, liners, fuel‑injection components, and valve‑train parts preserve designed clearances, combustion geometry, and timing. This ensures that the BA16M816 OEM parts interface precisely with mating surfaces, maintaining compression, oil control, and injector spray patterns that directly influence fuel efficiency, emissions, and thermal loading.

Using OEM spare parts suitable for BA16M816 supports:

Performance: Correct nozzle flow rates, pump elements, and turbocharger components sustain the engine’s rated output and transient response. Reliability: Metallurgy and heat‑treatment specifications used in the BA16M816 by MWM & Deutz are reflected in the corresponding components, improving resilience under cyclical and thermal stresses. Service life: Dimensional fidelity in liners, bearings, and valves reduces accelerated wear, keeping overhaul schedules predictable and minimizing unplanned stops.

MOPA is a reliable partner for OEM spare parts suitable for BA16M816. With a focused portfolio, fast response, and technical understanding of the 816 series, MOPA supports purchasers, superintendents, and chief engineers in selecting the right BA16M816 OEM parts—from major overhauls to routine service kits. Streamlined logistics and documentation help align parts planning with dry‑dock windows and onboard maintenance routines.

Optimized procurement of BA16M816 OEM parts

Consolidating orders for OEM spare parts suitable for BA16M816 through MOPA simplifies sourcing, ensures compatibility across component revisions, and aligns delivery with service windows. This reduces administrative effort and supports consistent engine performance across fleets where the BA16M816 is deployed in mixed propulsion and auxiliary roles.

Conclusion: BA16M816 value and parts support

The BA16M816 stands out in the 816 series for its reliable medium‑speed performance, efficient fuel use, and service-friendly design—qualities that benefit cargo operators, passenger fleets, offshore vessels, and stationary power plants alike. Sustaining that performance depends on OEM spare parts suitable for BA16M816, which safeguard output, reliability, and component life. MOPA supplies OEM spare parts suitable for BA16M816 with the technical expertise and responsiveness required by modern marine and power operators.