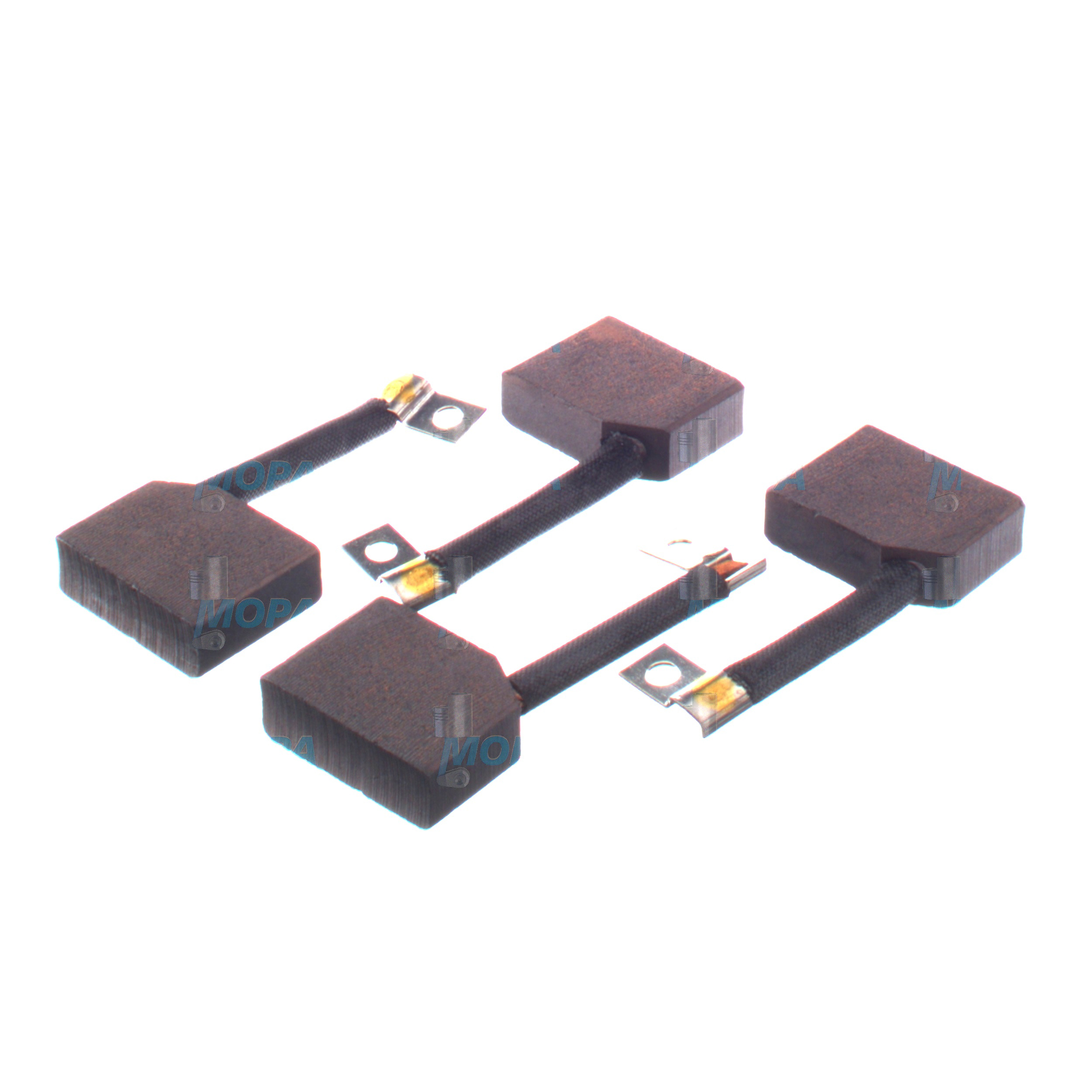

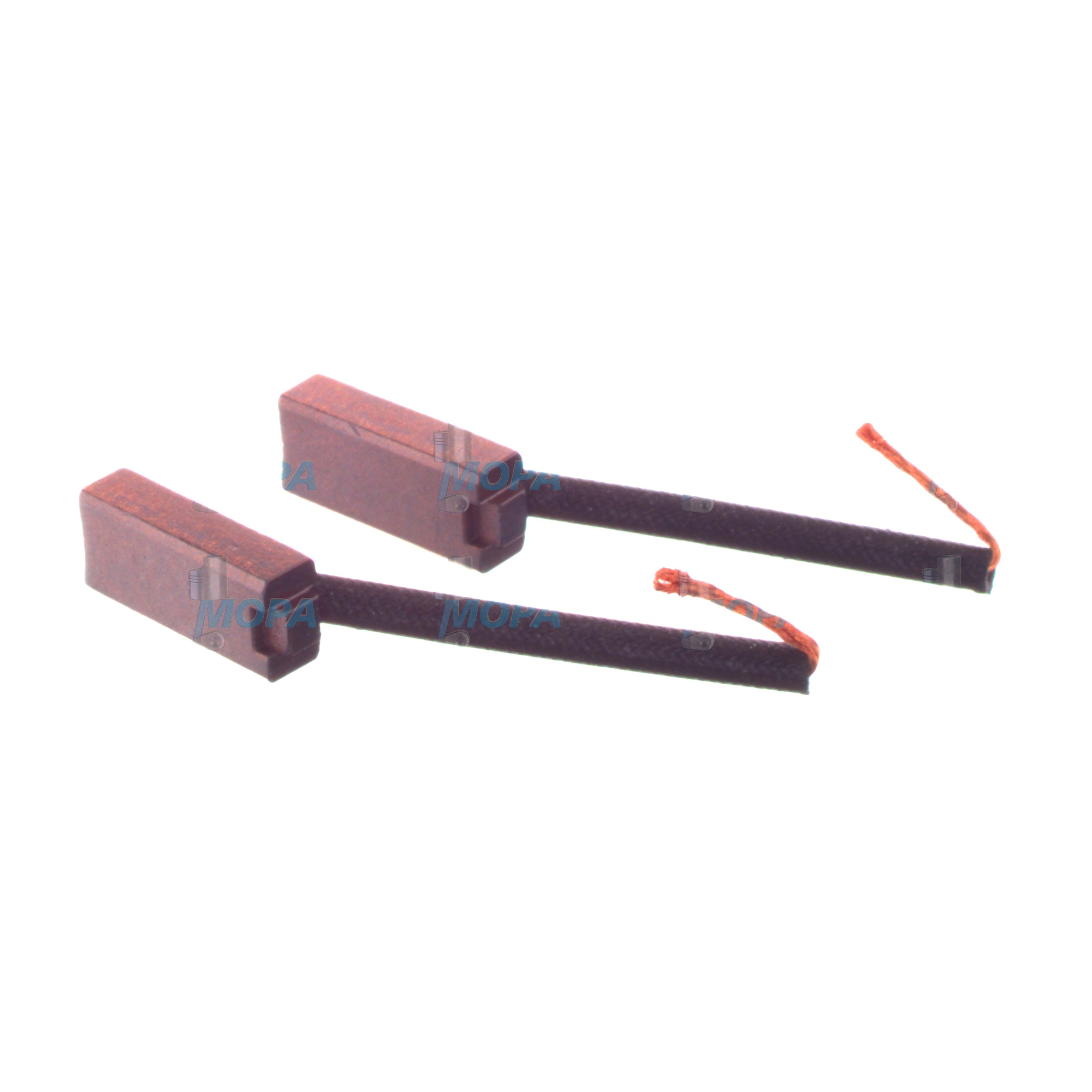

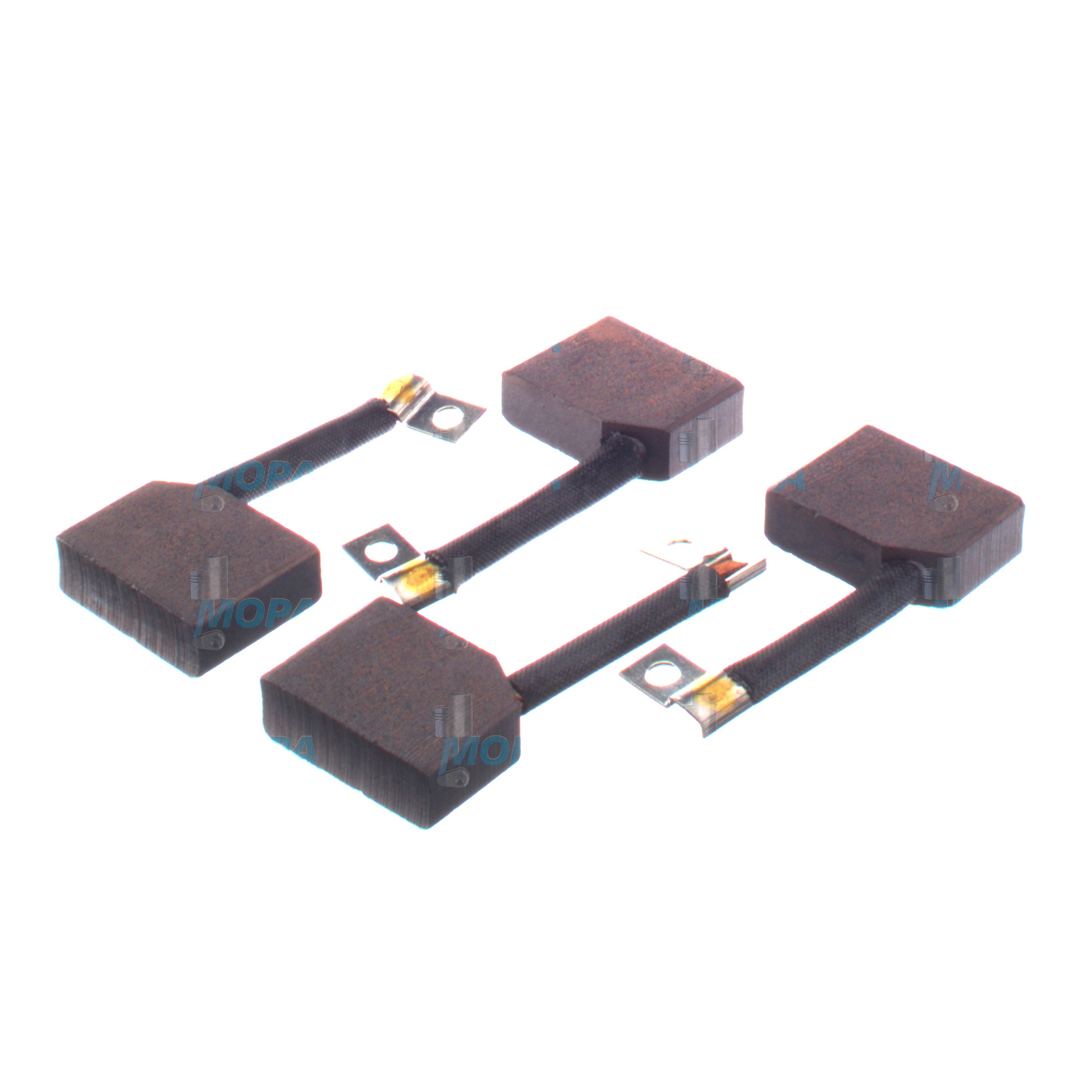

CARBON BRUSHES in Electric Components and Switches for Marine and Diesel Engines

Electric components and switches form the control and power backbone of any engine system. Within this category, assemblies such as contactors, relays, protection switches, sensors, voltage regulators, and CARBON BRUSHES ensure reliable starting, power generation, and safe operation. In a marine engine, a diesel engine, or a gas engine power plant, these components connect mechanical power to electrical functionality: they energize starter motors, stabilize generator output, protect circuits, and enable precise monitoring and shutdown when needed. Robust electric components and switches directly influence uptime, fuel efficiency, and safety—making them indispensable in ship propulsion, auxiliary gensets, and land-based industrial engines.

Technical function of Electric Components and Switches with CARBON BRUSHES in a diesel engine

Electric components and switches coordinate the complete electrical lifecycle of an engine. During start-up, high-current contactors and solenoids route power from batteries to starter motors. Sensors and control switches signal correct oil pressure, coolant temperature, and overspeed conditions to engine management. Once the prime mover is running, alternators and exciters produce electrical power for onboard or plant loads. Here, CARBON BRUSHES are critical: they maintain a low-resistance, stable interface between stationary brush holders and rotating commutators or slip rings in starters, DC machines, and brush-type alternators.

In practical terms, CARBON BRUSHES in a marine engine or diesel engine must balance conductivity, lubricity, and mechanical strength. The brush grade (e.g., electrographite, metal-graphite, resin-bonded) is selected to suit current density, voltage, and duty cycle. Correct spring pressure and brush-face geometry reduce arcing and ensure uniform wear across the commutator segments or slip rings. Proper commutation stabilizes generator voltage, limits heat, and protects windings. Meanwhile, switches and relays with arc-suppression features, correct contact materials, and appropriate IP ratings provide dependable isolation and control in harsh environments characterized by vibration, salt-laden air, and thermal cycling.

Voltage regulators and protection devices (overcurrent, undervoltage, reverse power, insulation monitoring) work together with switching gear to prevent equipment damage and to keep power quality within specification. When CARBON BRUSHES operate as intended, commutator films remain healthy, ripple is minimized, and electrical noise is reduced—supporting sensitive automation and navigation systems on board.

- · Reliable current transfer in rotating equipment

- · Low contact resistance and stable commutation

- · Heat-, vibration-, and corrosion-resistant switchgear

- · Accurate sensing and protective switching

- · Engineered brush grades for specific loads and voltages

- · Consistent fit and alignment for long service intervals

Why electric components and switches are vital for engine reliability

The reliability and service life of engines depend heavily on the condition of electric components and switches. Worn or misapplied CARBON BRUSHES increase sparking, causing commutator grooving, slip-ring pitting, and hot spots that degrade windings and bearings. The result can be unstable generator output, nuisance trips, or complete blackouts. Similarly, fatigued contactors or oxidized switch contacts create intermittent faults, excessive heat at terminals, and start failures—events that translate into costly downtime, schedule disruptions, and potential safety incidents.

Condition-based maintenance is essential: brush length inspections, spring-pressure checks, commutator surface assessment, and thermal scans of switchgear catch early deterioration. Keeping insulation resistance within limits and replacing degraded sensors or switches maintain the protective layers that prevent cascading failures. For vessels, offshore assets, and critical facilities, this preventive attention ensures propulsion availability and uninterrupted auxiliary power.

Advantages of OEM spare parts suitable for Electric Components and Switches

Choosing OEM spare parts suitable for electric components and switches—including CARBON BRUSHES OEM parts—delivers measurable value. Parts produced to engine-maker specifications match the required dimensions, materials, and tolerances, which simplifies installation and reduces commissioning time. For brushes, the correct grade composition and density yield optimal film formation, low wear, and cool operation. For switches, accurate contact alloys, calibrated springs, and rated housings maintain switching performance under full load, fault, and environmental stress.

Beyond fit and function, OEM spare parts suitable for a diesel engine or marine engine electrical system are validated against relevant standards and test protocols. That means consistent performance across batches, predictable service intervals, and fewer unscheduled stoppages. Over the life of the asset, this translates into lower total cost, improved fuel efficiency via stable power quality, and extended life of commutators, slip rings, and contact assemblies.

Procurement teams also benefit from streamlined logistics: precise part numbers, documented traceability, and compatibility with existing drawings reduce the risk of rework or delays. The result is dependable performance, controlled budgets, and a longer service life for critical electrical subsystems.

MOPA: your partner for OEM spare parts Electric Components and Switches

MOPA supplies OEM spare parts suitable for Electric components and switches with a focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines. Whether you need CARBON BRUSHES for a marine engine alternator, heavy-duty contactors for a propulsion switchboard, or calibrated sensors for a genset controller, MOPA combines technical expertise with a reliable supply chain. You can expect fast quotations, short lead times, and fully documented deliveries to keep projects and maintenance windows on schedule.

Our team assists with brush grade selection, slip-ring/commutator compatibility, and switchgear ratings to ensure every part meets the operational profile of your engine. With robust sourcing, inspection, and packaging processes, MOPA provides the confidence that your electrical components will perform as specified—voyage after voyage, shift after shift.

CARBON BRUSHES marine engine and diesel engine applications

From shaft-driven generators and emergency gensets to DC starter motors and excitation systems, CARBON BRUSHES support clean commutation and reliable power delivery. In tandem, switches, relays, and protection devices coordinate safe starts, controlled load transfers, and rapid fault isolation. Selecting OEM spare parts suitable for this category maintains the precise interplay between mechanical rotation and electrical control that keeps engines efficient, safe, and ready.

Conclusion

Electric components and switches—especially high-quality CARBON BRUSHES—are central to dependable engine operation and power management. Using OEM spare parts suitable for Electric components and switches safeguards performance, extends service life, and protects budgets through reduced downtime and predictable maintenance.