DIV.MTU marine engine type for MTU ALLG. — technical profile, applications, and OEM parts

DIV.MTU represents a versatile engine type designation widely used across MTU’s MTU ALLG. series, bringing together proven high-speed diesel technologies for demanding marine and stationary duties. While MTU and the MTU ALLG. portfolio provide the broader context, the focus here is on what makes DIV.MTU distinct: adaptability, power density, and service-ready integration for professional operators who need dependable output with tight operational control.

Whether driving propulsion on fast craft or delivering continuous power in a generator set, a DIV.MTU diesel engine is engineered for efficient, clean combustion and stable performance under varying loads. Buyers and technical decision-makers value the combination of rugged mechanics, sophisticated electronic control, and a configuration range that scales from compact inline layouts to powerful V-engines. In short: DIV.MTU by MTU is a strong choice wherever responsiveness, uptime, and lifecycle efficiency matter.

Technical profile of DIV.MTU marine engine

The DIV.MTU engine type typically spans multiple configurations to fit diverse vessel and plant requirements. Common architectures include inline and V-formats with high-pressure turbocharging and charge-air cooling. Electronic engine management ensures precise fuel metering and optimized timing, enabling low specific fuel oil consumption and consistent emissions performance. Depending on the selected configuration, operators can expect:

- Cylinder arrangements from 6 to 20 cylinders, inline or V, supporting a wide range of duty cycles.

- Power output bands commonly from approximately 400 kW to well above 10,000 kW, covering propulsion and auxiliary needs.

- Speed ranges from roughly 600 rpm for heavier-duty applications up to about 2,000 rpm for high-speed profiles.

- Total displacement scaled to application, from tens to several hundred liters, balancing torque delivery with compact footprints.

- Compliance-ready setups that can integrate aftertreatment to meet IMO and regional emission requirements, where applicable.

Advanced features in a DIV.MTU marine engine often include refined fuel systems (e.g., common-rail injection), optimized turbo-match for transient response, and robust cooling and lubrication circuits for continuous operation. Material choices and core design target durability in salt-laden environments, while modular auxiliaries simplify installation in tight engine rooms and enable efficient service access.

- · High power-to-weight ratio for compact installations.

- · Responsive torque curve for maneuvering and acceleration.

- · Efficient fuel burn through precise electronic control.

- · Broad configuration range to match vessel or plant profiles.

- · Class-approval pathways for international operations.

- · Maintenance-friendly layout to support planned overhauls.

Applications of DIV.MTU diesel engine in MTU ALLG.

DIV.MTU engines are selected across commercial, governmental, and industrial sectors because they deliver consistent output under real-world operating conditions. In shipping, typical applications include:

- Cargo vessels and coastal freighters requiring efficient propulsion and reliable auxiliary power.

- Passenger ferries and fast craft that prioritize acceleration, low vibration, and predictable fuel costs.

- Offshore support vessels where load steps, DP modes, and 24/7 utilization demand stable performance.

- Tugs and workboats seeking robust torque and dependable bollard pull.

- Patrol boats and special-purpose craft needing high-speed response and compact engine room integration.

Beyond propulsion, a DIV.MTU diesel engine sees duty in stationary and hybrid marine power systems. In power generation, it supports main gensets for shipboard electrical networks, shoreside backup, or peak-lopping installations. With appropriate controls and alternator pairing, DIV.MTU configurations can deliver steady frequency, rapid load acceptance, and improved efficiency at partial load—key for hoteling loads, crane operations, and critical onboard services.

Why operators value the DIV.MTU MTU marine engine

Operators consistently rate DIV.MTU highly for lifecycle economics, supported by strong power density and a serviceable design. The integration of electronic control enables fine-tuned combustion and cleaner exhaust profiles, while robust base-engine engineering supports long service intervals. The result is predictable performance, streamlined maintenance planning, and an attractive total cost of ownership for fleets where availability is non-negotiable. For SEO relevance and clarity: the DIV.MTU marine engine from MTU in the MTU ALLG. series is a trusted choice among shipowners and plant operators, and DIV.MTU OEM parts support the engine’s long-term reliability.

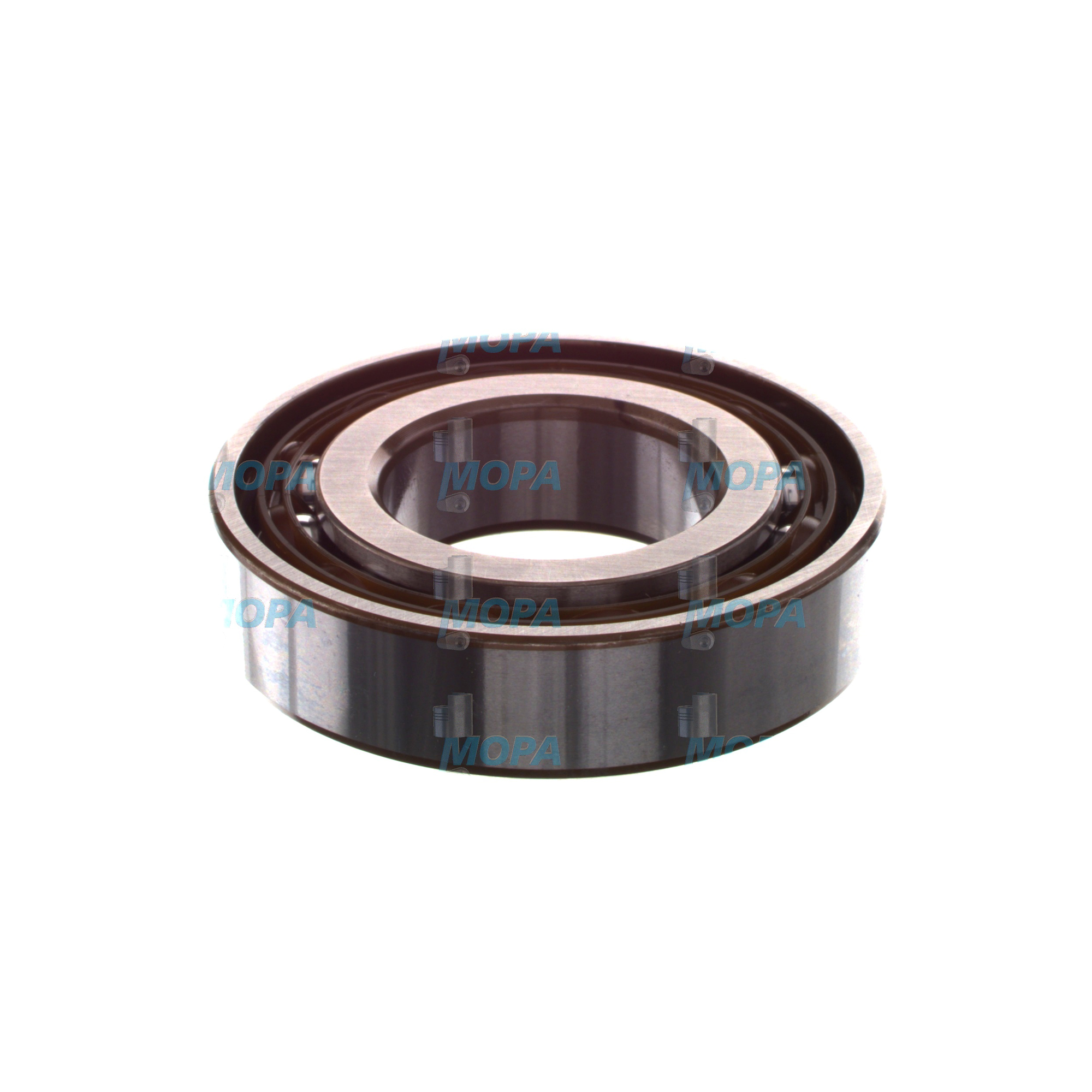

OEM spare parts suitable for DIV.MTU: performance, reliability, service life

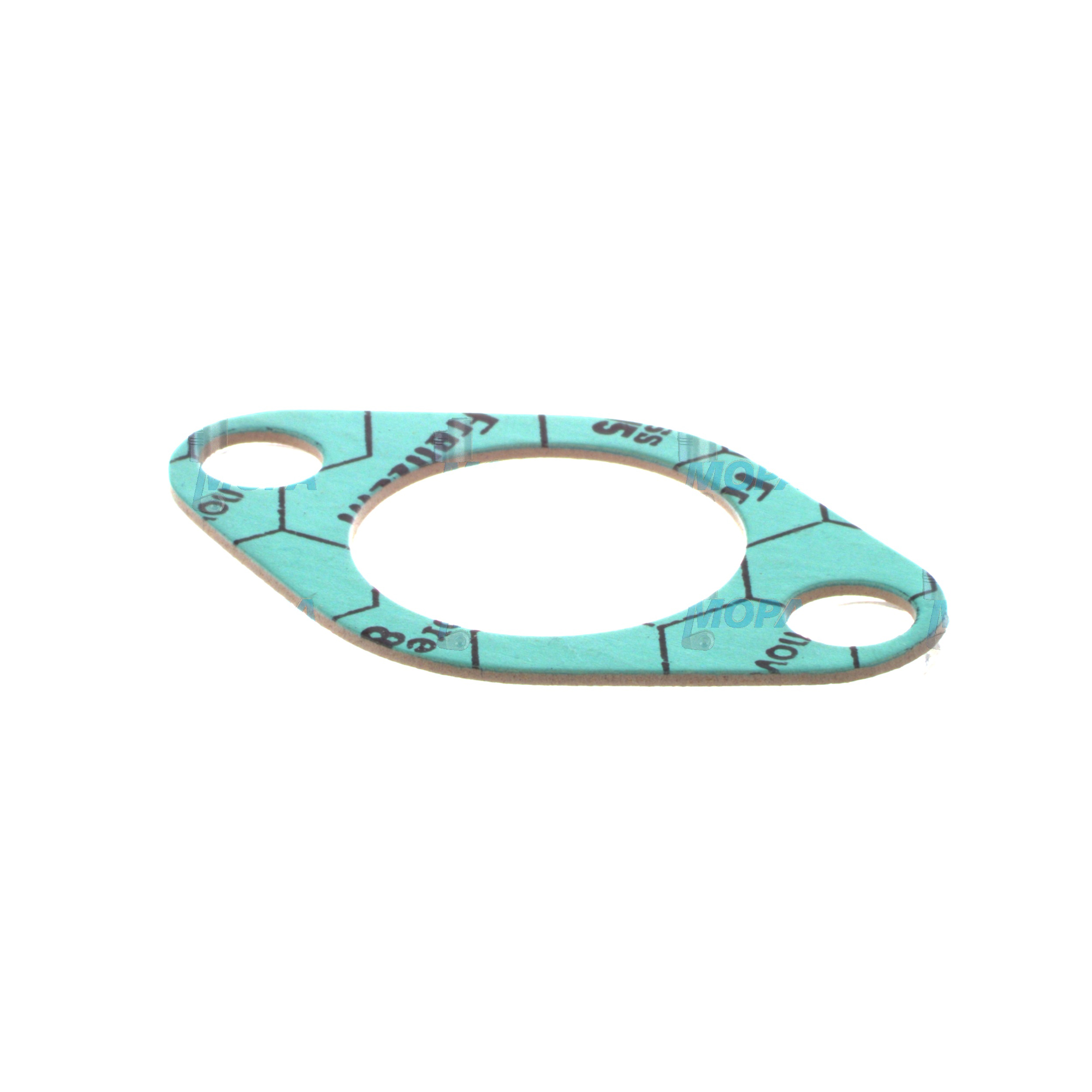

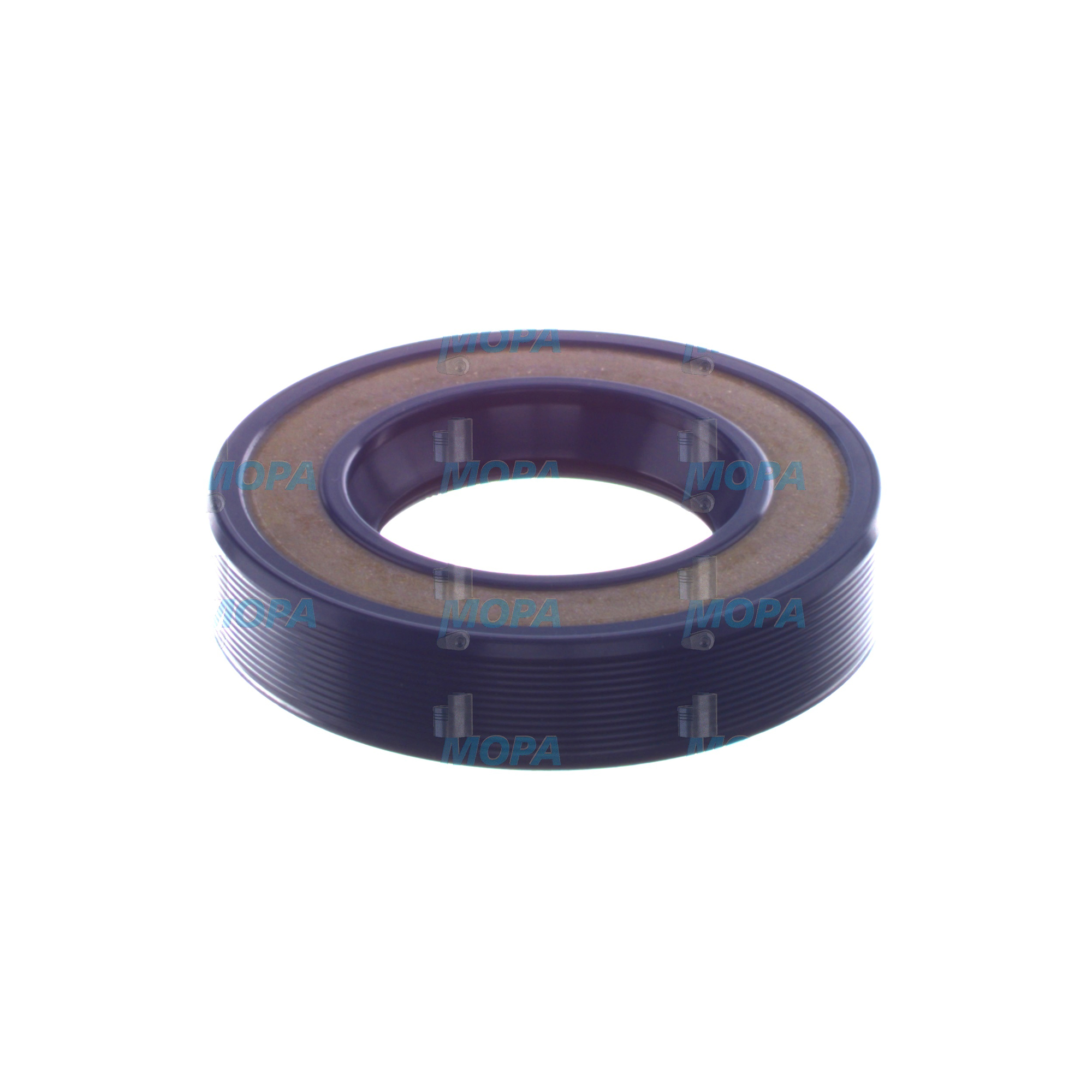

Using OEM spare parts suitable for DIV.MTU is central to preserving the engine’s designed performance envelope. Components manufactured to the specified dimensions, materials, and heat treatments ensure correct fit, stable clearances, and consistent sealing. In fuel systems, turbochargers, cooling circuits, and rotating assemblies, even small deviations can degrade efficiency, increase thermal stress, or shorten overhaul intervals. OEM spare parts suitable for DIV.MTU help maintain combustion quality, protect emissions compliance, and sustain load acceptance across the full operating range.

- · Precise tolerances support optimal fuel injection and timing.

- · Consistent material quality resists marine corrosion and fatigue.

- · Reliable sealing reduces oil carryover and coolant losses.

- · Stable performance protects class compliance and audit readiness.

- · Reduced downtime through predictable fit and installation.

- · Better lifecycle economics via sustained efficiency and longer service life.

MOPA — reliable partner for OEM spare parts suitable for DIV.MTU

MOPA supplies OEM spare parts suitable for DIV.MTU with a focus on availability, documentation, and fast response. From planned maintenance kits to critical-path components, MOPA streamlines sourcing, helps align parts with engine serial references, and supports shipment to ports and yards worldwide. For purchasers and technical teams, this means fewer supply bottlenecks, clear traceability, and parts that keep a DIV.MTU diesel engine operating to specification. When lead time, correctness, and performance matter, MOPA is a reliable partner for OEM spare parts suitable for DIV.MTU.

Conclusion: DIV.MTU diesel engine advantages and secure parts supply

DIV.MTU delivers the combination of power density, efficiency, and configurability that modern fleets and plants demand. Its strong technical foundation and proven track record across marine and stationary roles make it a sound choice for long-term operations. To preserve this performance over the engine’s life, MOPA provides OEM spare parts suitable for DIV.MTU, helping operators protect reliability, efficiency, and service life with every maintenance cycle.