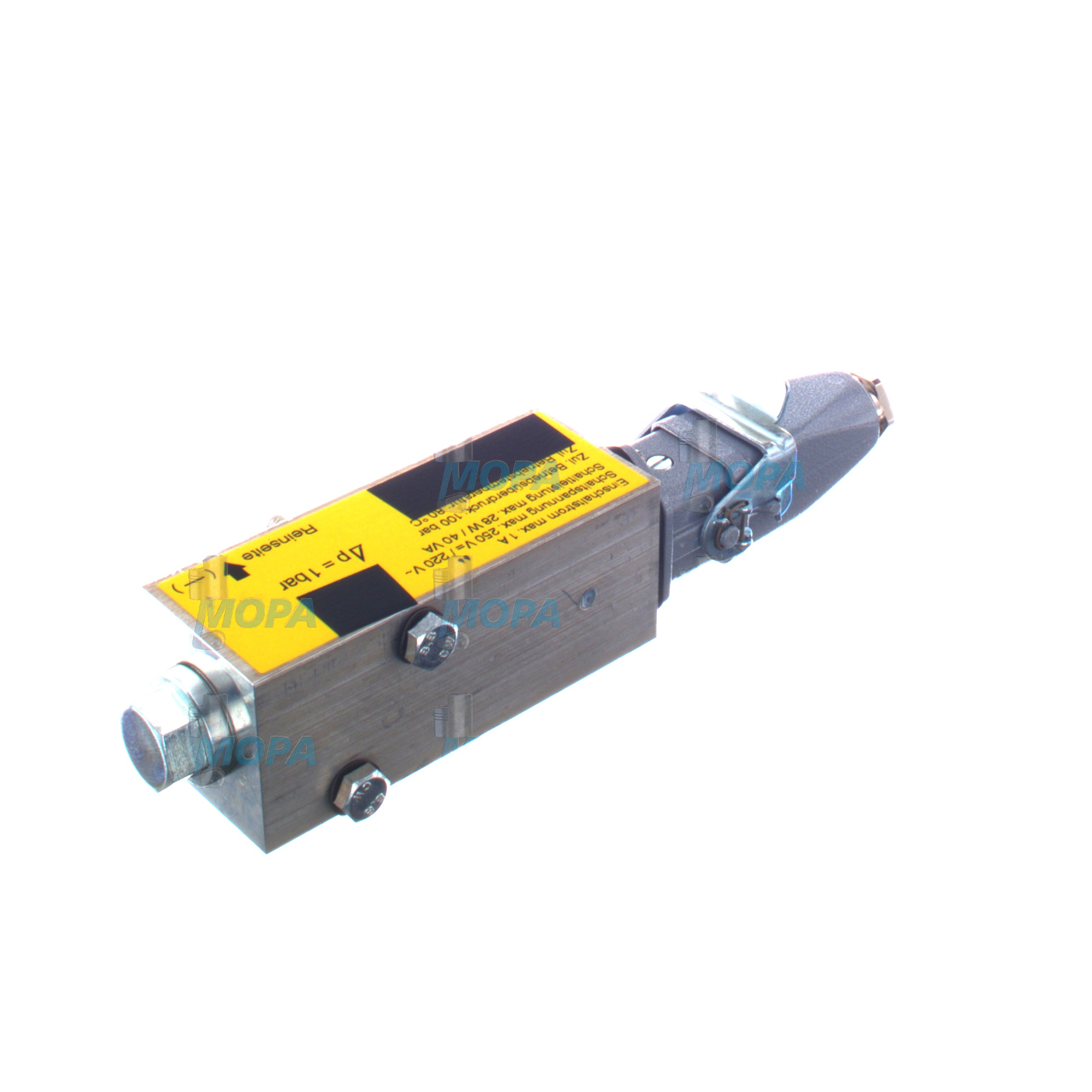

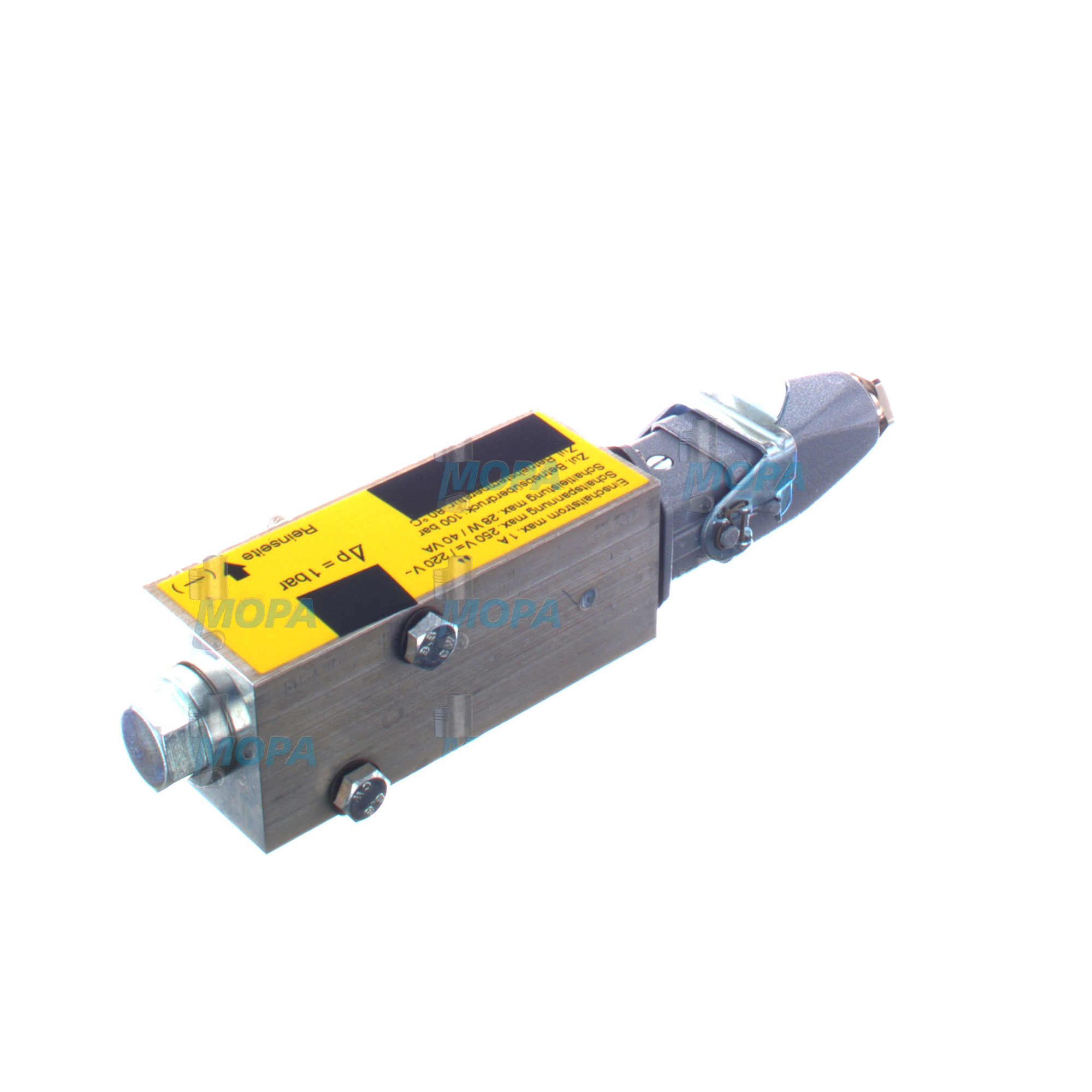

MAINTENANCE SWITCH and Electric Components and Switches for Heavy-Duty Engines

Electric components and switches form the nervous system of modern engines. From battery isolation and starter actuation to sensor feedback, protection, and control logic, this article category covers the devices that distribute power, route signals, and secure operating safety. Whether installed on a marine engine, a high-output diesel engine, or a gas genset, robust switching and control hardware determines how reliably an engine starts, runs, and shuts down. Within this family, the MAINTENANCE SWITCH is central to safe service procedures and power isolation, ensuring crews can work on equipment without accidental energization.

In engine rooms, control cabinets, and local panels, electric components and switches include battery and MAINTENANCE SWITCH units, contactors, relays, circuit breakers, pushbuttons, selector switches, limit switches, emergency-stop (E‑stop) devices, governors and ECU wiring, charging regulators, terminal blocks, and sensor interfaces. Their job: deliver stable power, provide precise signals, and protect both people and machinery in harsh conditions with vibration, salt-laden air, oil mist, and heat.

MAINTENANCE SWITCH integration: technical function of electric components and switches

At the core, switches define and interrupt current paths. In a diesel engine, the MAINTENANCE SWITCH isolates the battery bank or control supply before service, preventing unintended cranking and eliminating live circuits at the engine. In a marine engine, a lockable MAINTENANCE SWITCH allows lockout/tagout procedures that comply with yard and class requirements. Upstream, high-current battery switches and contactors handle starter currents that can exceed hundreds of amperes; downstream, control switches and relays deliver low-noise signals to the ECU, governor, and safety chain. Overcurrent protection devices (MCCBs, MCBs, fuses) limit fault energy, while E‑stops and interlocks provide fail-safe shutdown paths.

Key performance comes from contact design, arc suppression, and insulation. Silver‑tin oxide contacts resist welding under high DC loads; magnetic blowout or arc chutes stretch and extinguish arcs; housings and boots with IP67/IP69K sealing keep moisture out; terminals with defined torque values maintain low resistance. On the signal side, gold‑plated contacts and shielded cable glands preserve signal integrity for speed pickups, temperature probes, and pressure sensors. Integration is completed by harnesses and terminal blocks that ensure orderly routing, correct pinout, and fast troubleshooting. For traceability and service planning, MAINTENANCE SWITCH OEM parts often include data plates with current ratings, duty class, and approval marks.

- · Safe power isolation for service and inspection.

- · High current capability for starter and charging circuits.

- · IP-rated sealing against water, oil, and salt spray.

- · Vibration-resistant design and locking hardware.

- · EMC-compliant construction for clean ECU signals.

- · Clear actuation feedback, with lockable positions.

- · Thermal and short-circuit protection coordination.

- · Class-compliant materials and markings for marine use.

In practice, a MAINTENANCE SWITCH for a marine engine is often key-operated or padlock-ready, carry ratings such as 300 A continuous at 24 VDC with short-duration peaks for cranking, and be mounted near the battery room or engine skid. Control switches—start/stop, local/remote, speed setpoint—interlock with safety relays so that an engine cannot engage propulsion or connect to a bus under unsafe conditions. Sensors and limit switches trigger alarms or shutdowns if oil pressure dips, coolant temperature rises, or overspeed is detected.

Why electric components and switches are critical for engine reliability and service life

Reliability starts with stable electrical paths. Contact oxidation, loose cable lugs, or undersized conductors create voltage drops and heat, causing hard starts, nuisance trips, and accelerated alternator wear. A mis-specified control switch can introduce electrical noise into the governor loop, degrading speed stability and fuel efficiency. Corrosion inside non-sealed switches leads to intermittent signals that complicate diagnostics and erode confidence in safety circuits.

When the MAINTENANCE SWITCH in a diesel engine cannot fully isolate power, technicians risk exposure to live circuits or unintended starter engagement. Conversely, a properly rated and correctly wired MAINTENANCE SWITCH provides a predictable isolation point, enabling safe work and faster turnaround. Over time, quality electric components and switches extend service intervals, reduce thermal stress on cables and terminals, protect expensive rotating equipment, and minimize unplanned stops that can disrupt vessel schedules or power contracts.

Advantages of OEM spare parts suitable for Electric Components and Switches

Choosing OEM spare parts for electric components and switches safeguards performance, reliability, budget, and service life. These components are validated to the engine maker’s electrical loads, duty cycles, and environmental conditions, ensuring that a MAINTENANCE SWITCH or control relay operates within its proven thermal and mechanical window. Dimensional accuracy and the correct pinout prevent wiring errors. Contact materials, spring forces, and arc-quenching geometries match the original design intent of the starter circuit, ECU inputs, and protection chain.

From a cost perspective, the right fit reduces installation time, avoids rework, and minimizes troubleshooting. Documented compliance with relevant standards (e.g., IEC/EN, marine class approvals) streamlines inspections and audits. With OEM parts, purchasers benefit from consistent quality batches, serial number traceability, and the confidence that the part is engineered to cooperate with adjacent components—cables, breakers, sensors—across the engine platform. For a MAINTENANCE SWITCH OEM parts solution, this means proper shaft travel, contact overlap, and lockout features that stand up to daily engine-room practice.

MOPA: fast, secure supply of OEM parts for MAINTENANCE SWITCH, electric components and switches

MOPA is an experienced and reliable partner for sourcing OEM spare parts in this category. The team supports purchasers, shipowners, and technical managers with quick quotations, dedicated cross-references, and global logistics for diesel and gas engines. Quality and security are built into every transaction: verified documentation, batch traceability, and careful packaging protect sensitive electrical hardware in transit. Whether you need a MAINTENANCE SWITCH OEM parts kit, class-approved circuit breakers, ruggedized control switches, or sensor interface modules, MOPA delivers speed, consistency, and peace of mind.

Conclusion: MAINTENANCE SWITCH and electric components ensure safe, efficient engines

Electric components and switches—led by the MAINTENANCE SWITCH for safe isolation—are fundamental to engine performance, efficiency, and safety. Selecting OEM spare parts suitable for Electric components and switches preserves design integrity, reduces downtime, and extends the service life of marine, diesel, and gas engines.