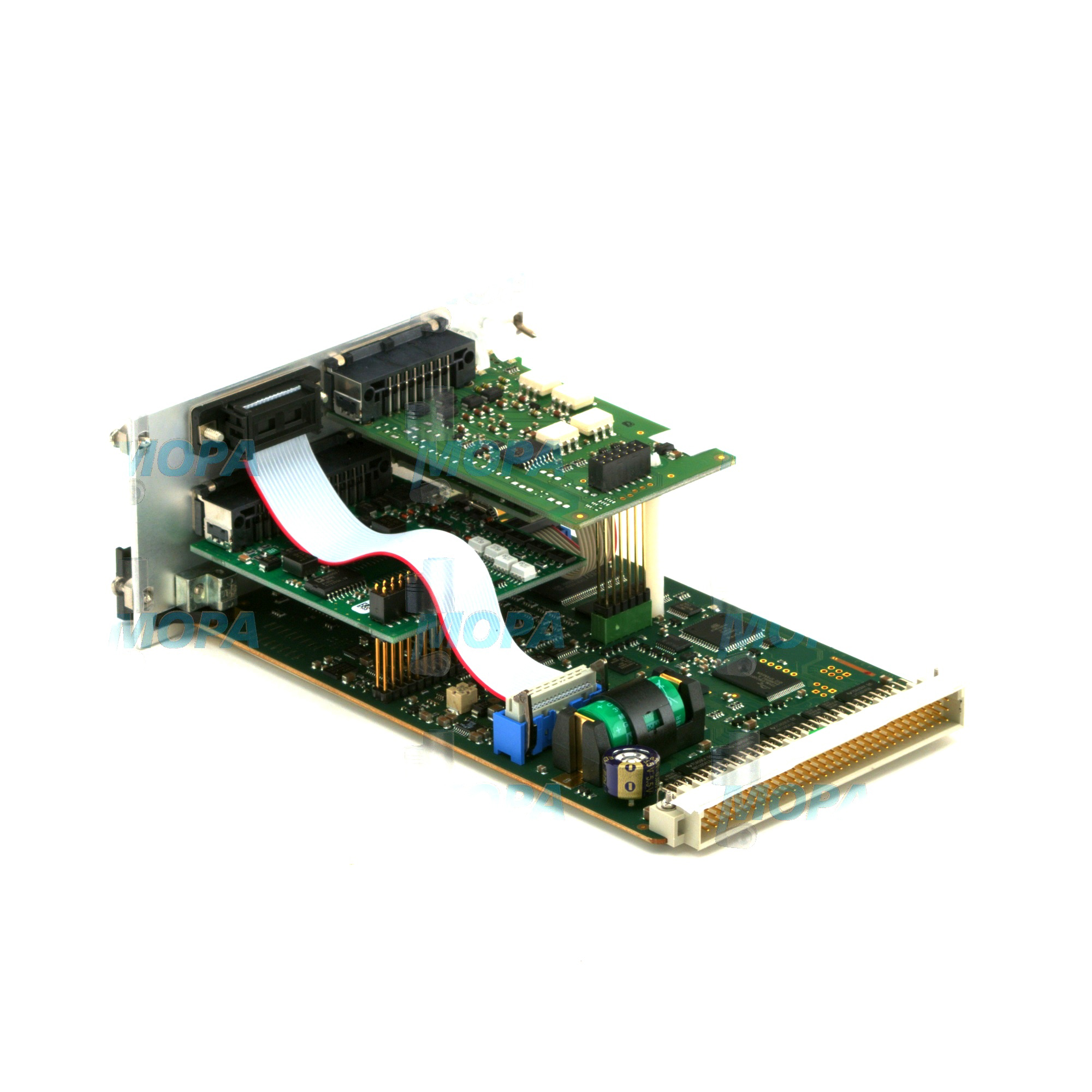

CPU/CENTRAL PROCESSING UNIT – Electric components and switches for professional engine control

Electric components and switches are the nervous system of modern propulsion and power-generation plants. In marine and industrial settings, they route power, transmit signals, and execute commands that keep engines running safely and efficiently. From start/stop switches and emergency shutdowns to relays, contactors, sensors, circuit breakers, and control modules, this article category covers the critical hardware that interfaces with the engine’s brain: the CPU/CENTRAL PROCESSING UNIT. In a marine engine or diesel engine, these components must withstand vibration, heat, moisture, and electromagnetic interference—yet deliver precise, repeatable performance around the clock.

While the CPU/CENTRAL PROCESSING UNIT coordinates logic, timing, and protection, electric components and switches provide the hands and eyes that act on that logic—energizing starters, modulating fuel and air, protecting circuits, and feeding reliable data back to the controller. Together, they form a tightly integrated control architecture that determines responsiveness, fuel economy, emissions, and operational safety.

Technical function: Electric components and switches with CPU/CENTRAL PROCESSING UNIT control

In a diesel engine or marine engine, the CPU/CENTRAL PROCESSING UNIT ingests signals from pressure, temperature, speed, and position sensors via shielded harnesses and I/O modules. It computes ignition or injection timing, fuel rack position, turbo bypass actuation, and cooling or lube oil control. Electric components and switches—relays, solid-state drivers, solenoid valves, limit switches, and pushbuttons—execute these commands in milliseconds. Circuit breakers and fuses isolate faults; contactors switch high current; E-stop chains and overspeed trips enforce safety; selector and key switches define operating modes. The result is deterministic engine behavior under all load cases, whether operating as a single prime mover or synchronized within a genset.

On digitally managed platforms, the CPU/CENTRAL PROCESSING UNIT communicates with distributed modules via CAN bus (e.g., J1939), Modbus, or NMEA 2000. Electric components are specified for voltage (typically 24 VDC on marine systems), transient immunity, ingress protection (often IP65–IP67), and shock/vibration resilience per marine class rules. Correct pairing of the CPU/CENTRAL PROCESSING UNIT with the right switches, sensors, and power switching devices ensures clean signals, stable actuation, and minimal electromagnetic emissions—conditions that directly affect performance, fuel efficiency, and alarm integrity.

- · High vibration resistance and long mechanical life.

- · Precise switching thresholds for stable engine control.

- · Corrosion-resistant materials for marine environments.

- · Clear labeling and plug-in interfaces for fast service.

- · Proper EMC shielding for reliable CPU communication.

- · Thermal protection and correct current ratings.

- · Compatibility with CPU/CENTRAL PROCESSING UNIT I/O levels.

- · IP-rated enclosures and connectors.

When the control loop is closed—CPU computes, electric components switch, sensors confirm—the engine reaches target speed and load with minimal overshoot, steady exhaust temperatures, and compliant emissions. In multi-engine setups, load sharing and power management depend on crisp switching and fault-free signals to and from the CPU/CENTRAL PROCESSING UNIT.

Importance for continuous engine operation and service life

Electric components and switches directly influence uptime. Degraded contacts, corroded terminals, or drifting sensor outputs can cause intermittent shutdowns, nuisance trips, false alarms, or derating. In severe cases, a sticking relay or miswired switch can prevent an emergency stop or trigger uncontrolled cranking—serious safety risks for crew and equipment. Voltage drops across aged connectors reduce actuator authority and distort the readings the CPU/CENTRAL PROCESSING UNIT relies on, leading to poor fuel mapping, unstable idle, higher specific fuel consumption, and accelerated component wear.

In marine environments, salt mist, temperature cycles, and vibration accelerate failure modes: insulation cracking, contact pitting, fretting corrosion, and switch bounce. Prevention means selecting robust components and maintaining clean signal paths so the CPU/CENTRAL PROCESSING UNIT can execute its strategy without noise, losses, or delays. Over the engine’s lifecycle, this translates into fewer unscheduled stops, lower total cost of operation, and safer voyages.

Advantages of OEM spare parts suitable for Electric components and switches

Using OEM spare parts suitable for this category safeguards the design intent of the control system. The CPU/CENTRAL PROCESSING UNIT, I/O modules, and electric components are engineered as a matched set—electrical ratings, timing characteristics, connector pin-outs, and EMC behavior are tuned to work together. With OEM parts, the diesel engine controller sees the expected signal levels and response curves, resulting in stable mapping and predictable protective functions. For a marine engine, correct sealing, material grades, and shock ratings are critical, and OEM parts preserve those specifications.

Beyond fit and function, OEM components are validated on the target platform, supporting consistent performance across ambient conditions and load profiles. This reduces troubleshooting time, avoids software conflicts with the CPU/CENTRAL PROCESSING UNIT, and supports compliance with class and flag-state requirements. Reliability improves, spares stocking becomes simpler, and downtime costs decrease thanks to plug-and-play compatibility and proven test data.

- · Consistent performance with CPU/CENTRAL PROCESSING UNIT OEM parts.

- · Correct electrical ratings and calibrated thresholds.

- · Verified EMC behavior in engine rooms.

- · Faster commissioning and reduced downtime.

- · Long service life and predictable maintenance intervals.

- · Traceability and documentation for audits.

- · Lower lifecycle cost through reliable operation.

MOPA as your partner for OEM Electric components and switches

MOPA supplies OEM spare parts for electric components and switches—sensors, relays, contactors, breakers, pushbuttons, harnesses, and control modules—matched to the requirements of diesel and gas engines. As an experienced, reliable partner, MOPA emphasizes speed, quality, and security in the trade of OEM parts. We help you cross-reference part numbers to the correct CPU/CENTRAL PROCESSING UNIT interfaces, verify ratings and connector systems, and deliver components that integrate seamlessly with your marine engine or genset control system.

Fast, secure sourcing for CPU/CENTRAL PROCESSING UNIT and related OEM parts

With responsive logistics, careful ESD handling, and lot traceability, MOPA reduces lead times and mitigates risk in critical maintenance windows. From emergency shipments to planned overhauls, you receive properly specified components that maintain system integrity—so the CPU/CENTRAL PROCESSING UNIT, electric components, and switches perform as designed in demanding marine environments.

Conclusion

Electric components and switches are the decisive interface between the CPU/CENTRAL PROCESSING UNIT and the mechanical heart of a marine or diesel engine. Their quality and compatibility determine safety, efficiency, and uptime. Choosing OEM spare parts suitable for this category preserves control accuracy, reduces downtime, and protects your budget over the full engine lifecycle.