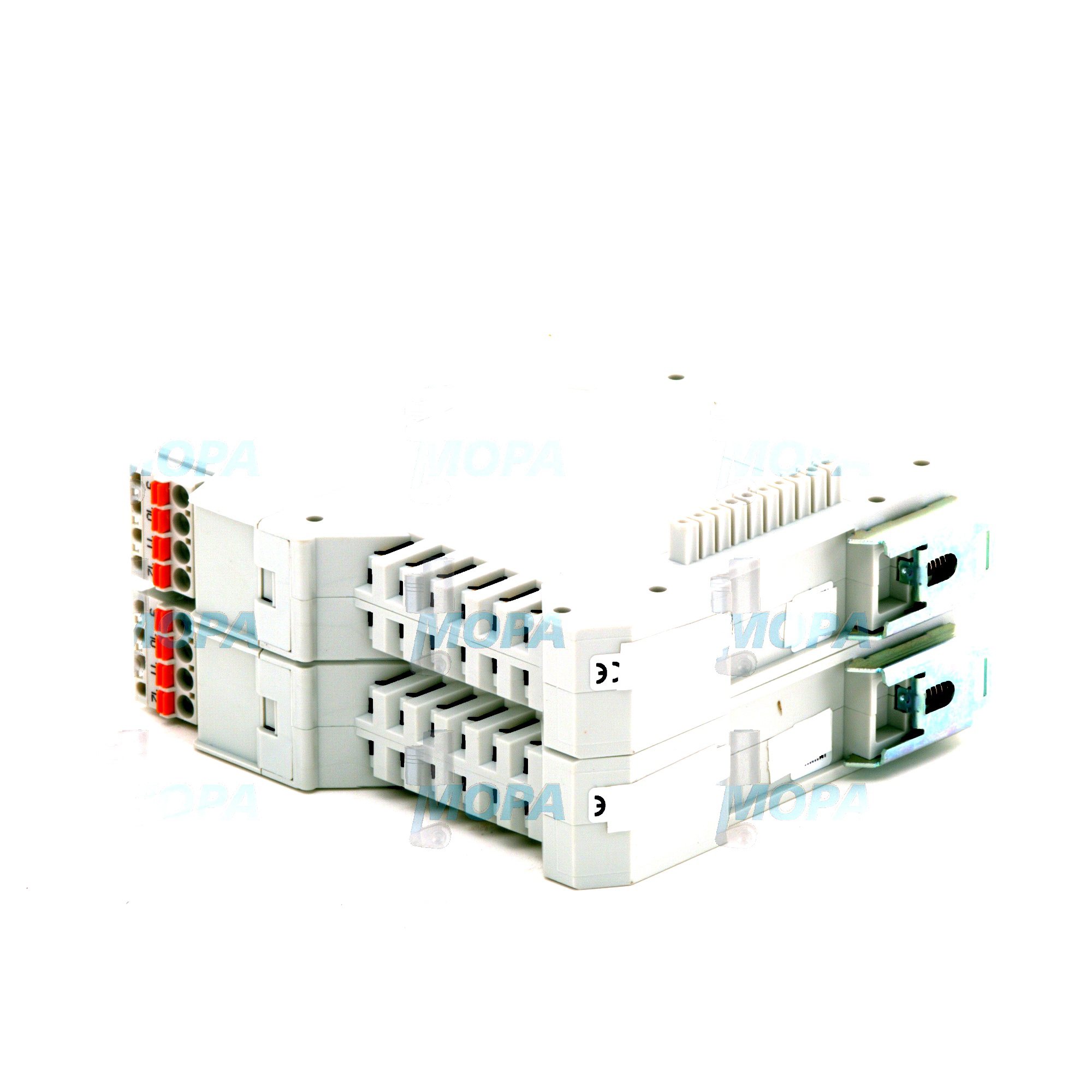

I/O CONTROLLER Electric components and switches for reliable engine automation

Electric components and switches are the backbone of engine automation, connecting sensors, actuators, and protection devices into a coherent control system. In marine and stationary applications, these devices transform mechanical and thermal realities into electrical signals that a controller can process. Contactors, relays, limit switches, pushbuttons, breakers, terminal blocks, and cable assemblies work alongside the I/O CONTROLLER to start, stop, protect, and optimize a diesel engine or gas engine. When specified and maintained correctly, they ensure stable power generation, propulsion, and auxiliary operation under demanding conditions at sea or on land.

Within this category, the I/O CONTROLLER acts as the central interface between the engine’s physical world and the control logic implemented in a PLC or ECU. Combined with high-grade electric components and switches, it delivers the accurate signal acquisition, deterministic actuation, and safety interlocking that modern engines require to meet performance, efficiency, and compliance targets.

I/O CONTROLLER technical function in diesel engine and marine engine systems

In an engine control cabinet, the I/O CONTROLLER aggregates digital and analog inputs—such as speed pick-up pulses, oil pressure, coolant temperature, charge air temperature, exhaust thermocouples, vibration, and fuel rack position—while managing outputs to solenoid valves, fuel pumps, heaters, ventilation fans, pre-lube pumps, and start/stop circuits. Paired with robust switches and contact devices, the controller converts sensor values into actionable logic for the PLC/ECU and executes precise, time-critical actuation.

For a marine engine, an I/O CONTROLLER rated for shipboard environments ensures stable operation despite electrical noise, vibration, and temperature swings. It typically provides galvanic isolation on channels, configurable scaling for transducers, debounce filtering for mechanical switches, and diagnostics such as open-circuit and short-circuit detection. In a diesel engine generator set, it supports speed and load control, overspeed and overtemperature trips, fuel limitation under transient conditions, and sequenced starting—including glow or preheat control for cold starts. When paired with OEM parts switches and relays, the controller maintains deterministic timing and safe fallback states during abnormal conditions.

Switchgear and auxiliary electric components complete the loop: contactors and motor protection breakers manage high-current feeders; limit and pressure switches provide hardwired confirmations for safety chains; emergency stop devices interrupt energy quickly; and terminal blocks with proper labeling keep maintenance efficient and error-free. Together, the components and the I/O CONTROLLER enable repeatable performance, reduce response latency, and reinforce safety barriers that are mandatory on classed vessels and industrial installations.

- · Precise signal conditioning for sensors and transducers.

- · Fail-safe outputs and clear diagnostics for faster troubleshooting.

- · Marine-grade immunity to vibration, temperature, and EMC noise.

- · Safe interlocks via hardwired switches and E-stop circuits.

- · Scalable channel counts for multi-engine rooms and auxiliaries.

- · Correct voltage ratings, IP protection, and contact durability.

- · Clean wiring with standardized terminals and connectors.

- · Reduced downtime through rapid fault isolation.

Importance for engine operation and lifecycle

Electric components and switches directly influence engine reliability, availability, and lifecycle cost. Contact wear, oxidized terminals, or misaligned limit switches can create false trips, nuisance alarms, or—worse—missed trip commands. An I/O CONTROLLER with degraded channels can misread pressure or temperature, causing incorrect fueling, poor emissions performance, unnecessary derating, or delayed shutdown during critical faults. For shipowners and power plant operators, these failures translate into lost voyages, blackouts, and expensive unplanned service interventions.

By maintaining the integrity of the I/O stack—controller, relays, breakers, actuation coils, and signal wiring—operators preserve stable combustion control, clean starts, proper cooldown sequences, and predictable safety actions. Correctly specified switches and components with the right IP rating, contact materials, coil voltage, and breaking capacity minimize heat buildup, arcing, and voltage drop. The result is consistent performance across load steps, reliable synchronization and load sharing, and extended service intervals.

Advantages of OEM spare parts suitable for Electric components and switches

Using OEM spare parts suitable for electric components and switches keeps engine automation within the designed tolerances. Fit and function alignment—matching connector pin-outs, contact spacing, coil burden, sensing ranges, and environmental ratings—prevents subtle faults that can evade quick diagnosis. Parts qualified for the I/O CONTROLLER and its companion devices preserve EMC immunity, isolation distances, and timing behavior, helping your diesel engine or marine engine operate as intended.

I/O CONTROLLER OEM parts benefits for marine engine and diesel engine applications

With suitable OEM spare parts, purchasers safeguard performance, reliability, budget, and service life in one decision. Compatibility reduces installation time and commissioning risk. Proven materials and contact designs deliver higher cycle life and lower resistance, improving efficiency and thermal margins in confined engine rooms. Unified documentation and traceability streamline audits and class inspections, while standardized spares simplify inventory and speed up repairs. Over the lifecycle, fewer failures and shorter downtimes directly protect total cost of ownership.

MOPA as a partner for OEM spare parts Electric components and switches

MOPA is an experienced, reliable partner for OEM spare parts in Electric components and switches, including I/O CONTROLLER modules, relays, contactors, breakers, and engineered wiring assemblies. We focus on speed, quality, and security in the trade of OEM parts for diesel and gas engines, ensuring that the correct variant, rating, and revision reaches your vessel or plant without delay. Our team supports technical identification, cross-referencing, and logistics, helping purchasers and superintendents minimize downtime while maintaining compliance and operational safety.

Conclusion

Electric components and switches—together with the I/O CONTROLLER—form the critical interface between the engine and its control logic, determining performance, safety, and uptime. Selecting OEM spare parts suitable for this category preserves functional integrity, reduces risk during maintenance, and extends the service life of diesel and marine engine installations.