BF6L913C marine and industrial diesel engine

The BF6L913C is a robust six‑cylinder in‑line diesel engine that has earned a strong reputation for dependable power in tough environments. Belonging to the Deutz 913 series, the BF6L913C focuses on straightforward mechanical engineering and air cooling to deliver reliable output with low operating complexity. While Deutz and the 913 family provide the broader platform, this text concentrates on the BF6L913C itself—its characteristics, use cases, and why it is a preferred choice for buyers who value efficiency, serviceability, and long service life.

As a turbocharged, charge‑air‑cooled variant, the BF6L913C balances compact dimensions with high power density. Thanks to its air‑cooled cylinder barrels and heads, it eliminates the need for a conventional liquid cooling circuit, making the engine particularly resilient in marine and stationary settings where corrosion, scaling, or coolant management can become cost drivers.

BF6L913C technical profile and performance

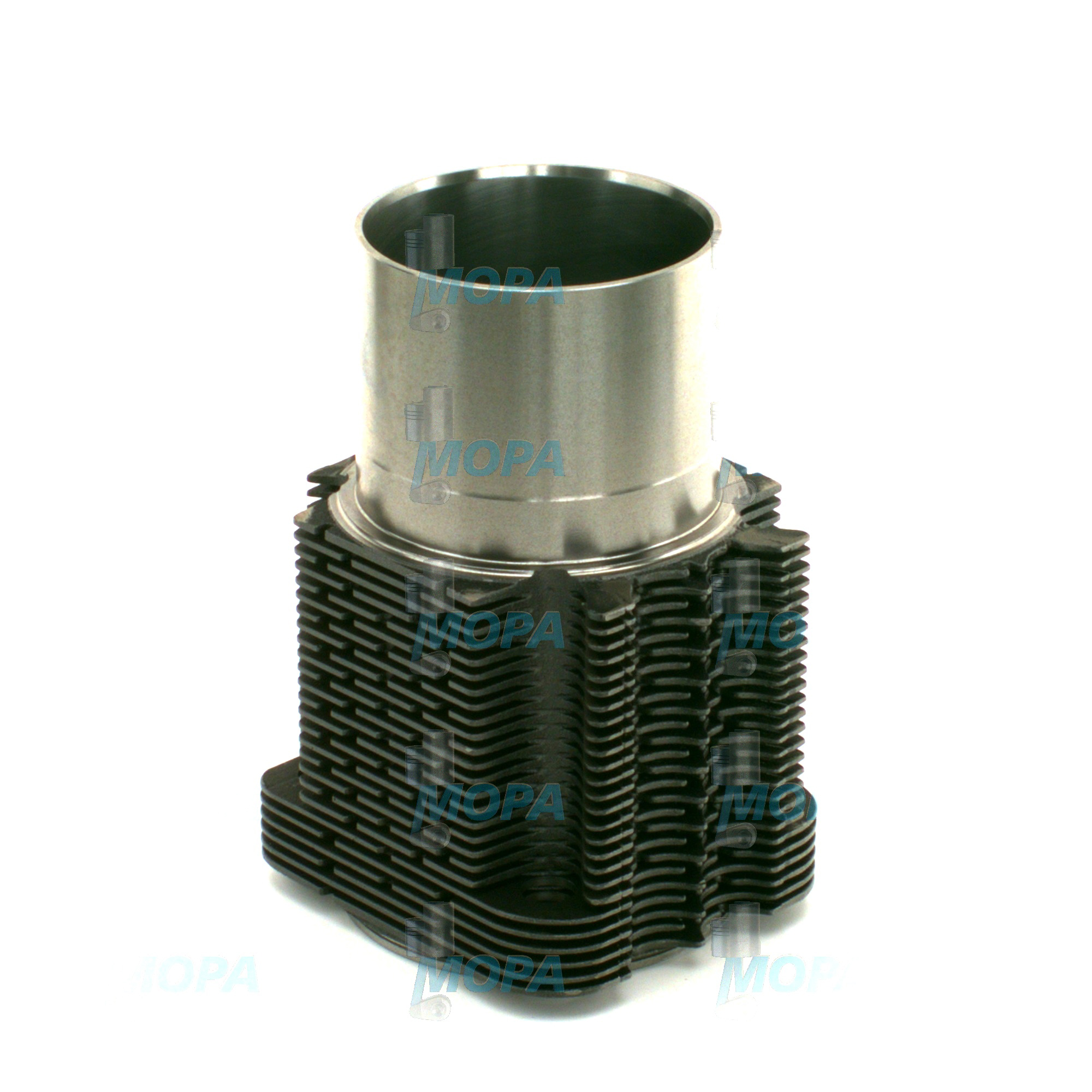

The BF6L913C is an in‑line 6‑cylinder, direct‑injection Deutz diesel engine featuring turbocharging and charge‑air cooling. The architecture is modular, with separate cylinder barrels and heads that simplify inspection and overhaul at the individual cylinder level. Typical power ratings are found in the medium range for this displacement class, suitable for 50/60 Hz gensets and auxiliary drives. Depending on configuration and rating, operating speeds commonly span from 1,500 rpm (prime power/generator applications) to around 1,800–2,300 rpm for various duty cycles. Displacement is in the approximately 6‑liter class, delivering a favorable balance of torque and fuel economy for extended runtimes.

Key technical characteristics of the BF6L913C include a mechanically governed fuel system, pressure‑time injection with proven reliability, and an air‑cooling concept that removes glycol management from the maintenance equation. For marine installations, the engine’s air‑cooled design means no raw water circulates through the engine block, reducing corrosion risks. Where required, dedicated oil coolers and ducted airflow ensure thermal stability under continuous load. The result is a BF6L913C diesel engine that is known for stable performance, even in hot or dusty conditions and around salt‑laden atmospheres found on offshore and coastal operations.

BF6L913C Deutz marine engine applications and use cases

The BF6L913C Deutz marine engine is widely used as an auxiliary and sometimes for light propulsion in commercial and governmental fleets. Its mechanical simplicity and ease of service make it a sensible choice for operations where uptime and predictable maintenance are paramount.

Typical applications include:

- Marine auxiliary gensets for cargo vessels, passenger ferries, and inland craft.

- Hydraulic power packs for deck machinery, winches, and cranes.

- Firefighting and bilge/pump drives on workboats and offshore support vessels.

- Stationary generator sets in ports, shipyards, and remote facilities.

- Industrial compressors and pumps in coastal or dusty climates.

Operators value the BF6L913C for its fuel efficiency in steady‑state loads, tolerance of variable fuel quality when maintained correctly, and straightforward diagnostics without complex electronics. In generator duty, the engine can be set for 50 Hz (1,500 rpm) or 60 Hz (1,800 rpm) operation, providing dependable electrical power for onboard systems or shore‑side facilities. The combination of turbocharging and charge‑air cooling enhances cylinder filling at rated speed, supporting clean combustion and consistent power delivery across a broad load range. In day‑to‑day terms, the BF6L913C diesel engine offers a proven pathway to low total cost of ownership.

Why the BF6L913C is widely adopted

Beyond its engineering fundamentals, the BF6L913C is popular because parts, service knowledge, and configuration options are available globally. The air‑cooled concept eliminates coolant leaks and freezing risks and reduces maintenance steps tied to heat‑exchanger scaling. Modular cylinders reduce downtime during overhauls: technicians can service single cylinders without removing the entire engine. These practical advantages translate to fewer surprises for purchasers and a predictable maintenance rhythm for shipowners and plant operators.

- · Six‑cylinder in‑line, turbocharged and charge‑air‑cooled.

- · Air‑cooled cylinders and heads; no glycol circuit required.

- · Mechanical fuel system for simple, reliable operation.

- · Typical speed ranges: 1,500–2,300 rpm depending on duty.

- · Power class suitable for 50/60 Hz marine and stationary gensets.

- · Modular cylinder design for efficient maintenance.

- · Proven in cargo, passenger, and offshore support environments.

- · Strong global parts and service ecosystem for long service life.

OEM spare parts suitable for BF6L913C: performance, reliability, service life

To sustain the performance profile of a BF6L913C marine engine, the quality and fit of service components matter. OEM spare parts suitable for BF6L913C are manufactured to the correct material specs, dimensional tolerances, and surface finishes that the combustion system, turbocharger, and air‑cooling pathways require. This precision safeguards injection timing and spray patterns, maintains proper compression and sealing, and preserves heat rejection through the engine’s cooling fins and airflow system. The outcome is stable output, clean combustion, and predictable fuel consumption across long operating intervals.

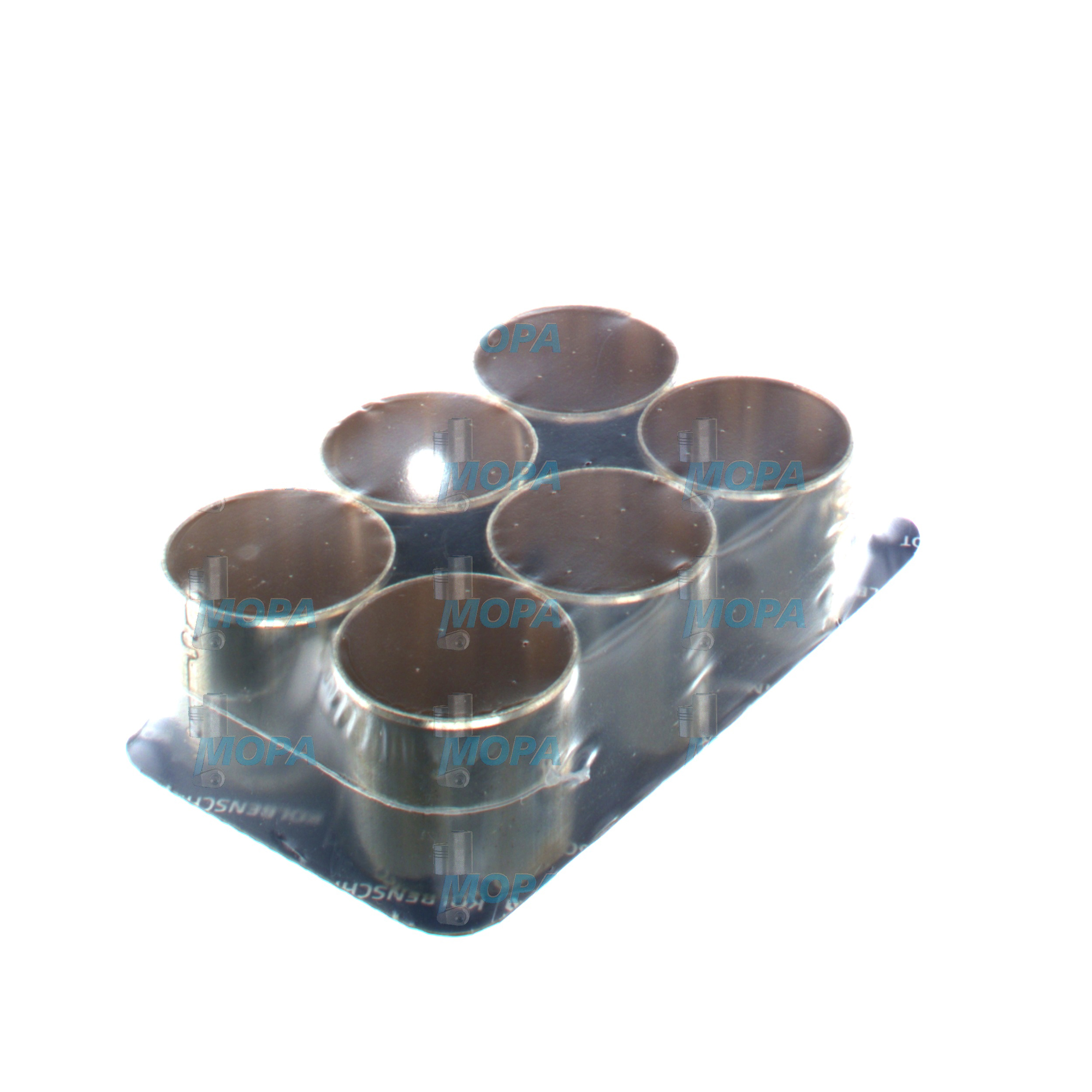

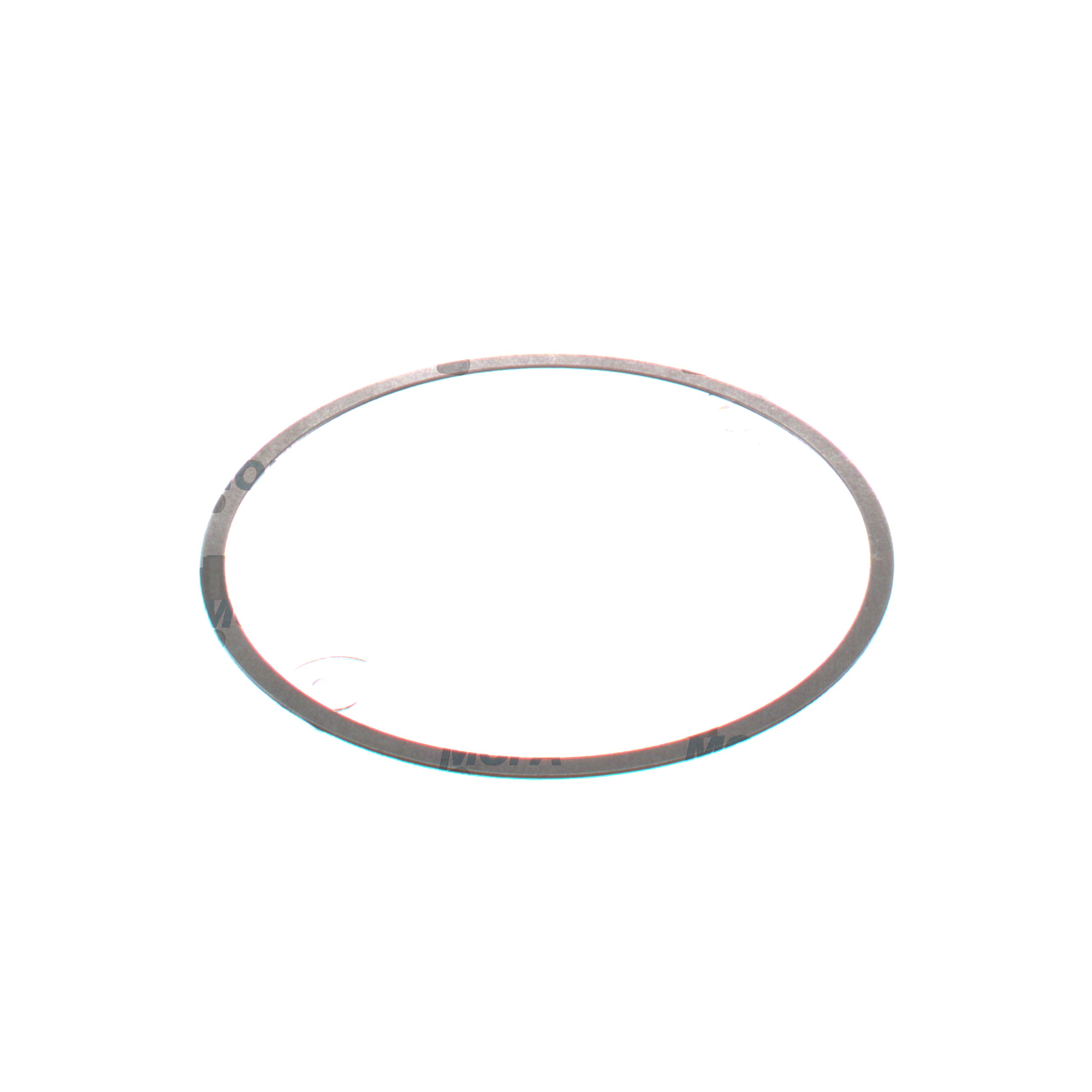

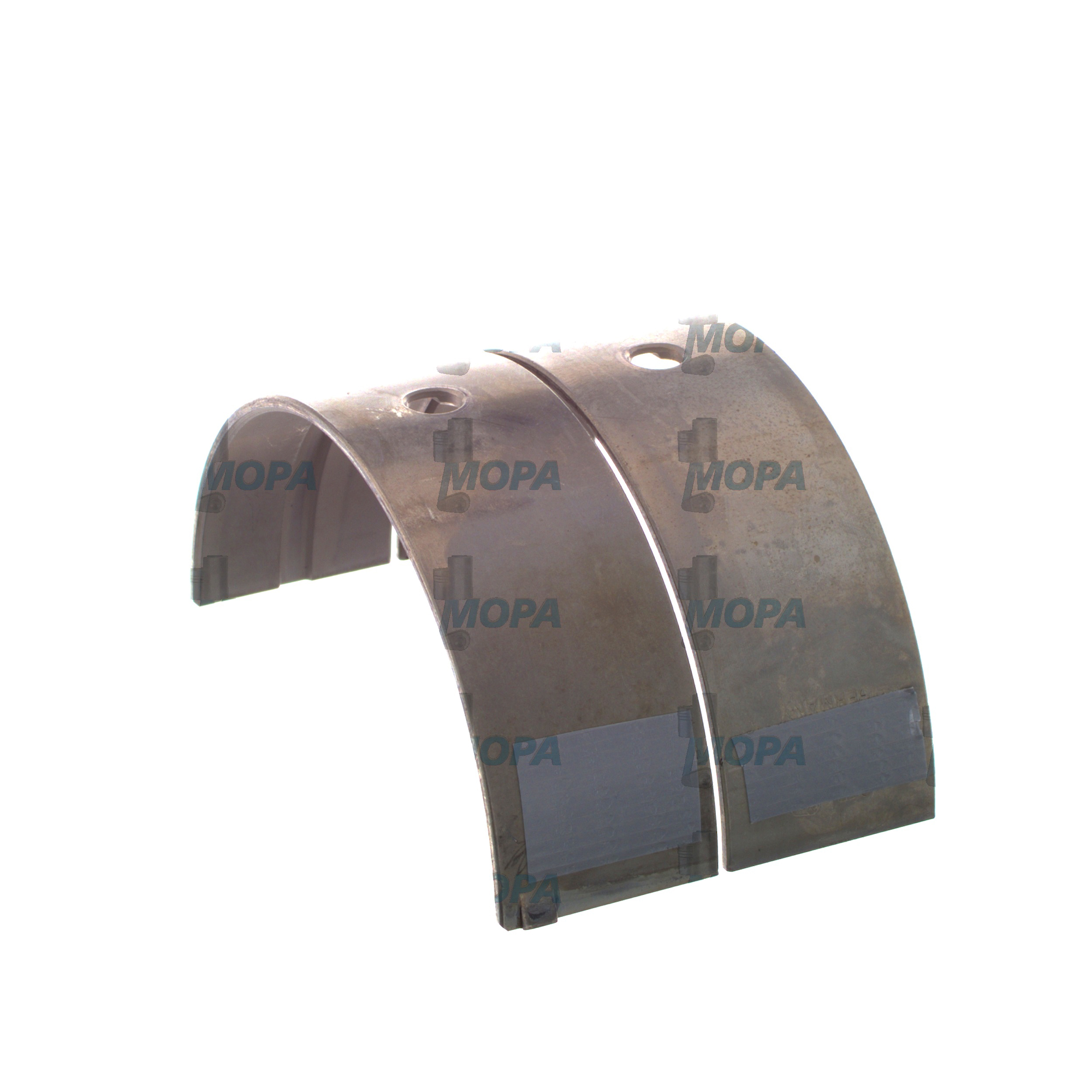

OEM spare parts suitable for BF6L913C also support reliability in continuous duty. Correctly matched pistons, rings, liners, valves, and gaskets help reduce blow‑by and oil carry‑over, while compliant filters, belts, and seals protect critical subsystems under thermal and vibrational stress. For operators who run BF6L913C Deutz diesel engine installations at fixed rpm—such as gensets supplying hotel loads or mission‑critical power—high‑quality components are essential for minimizing unplanned downtime and safeguarding key performance indicators like specific fuel consumption and exhaust temperatures.

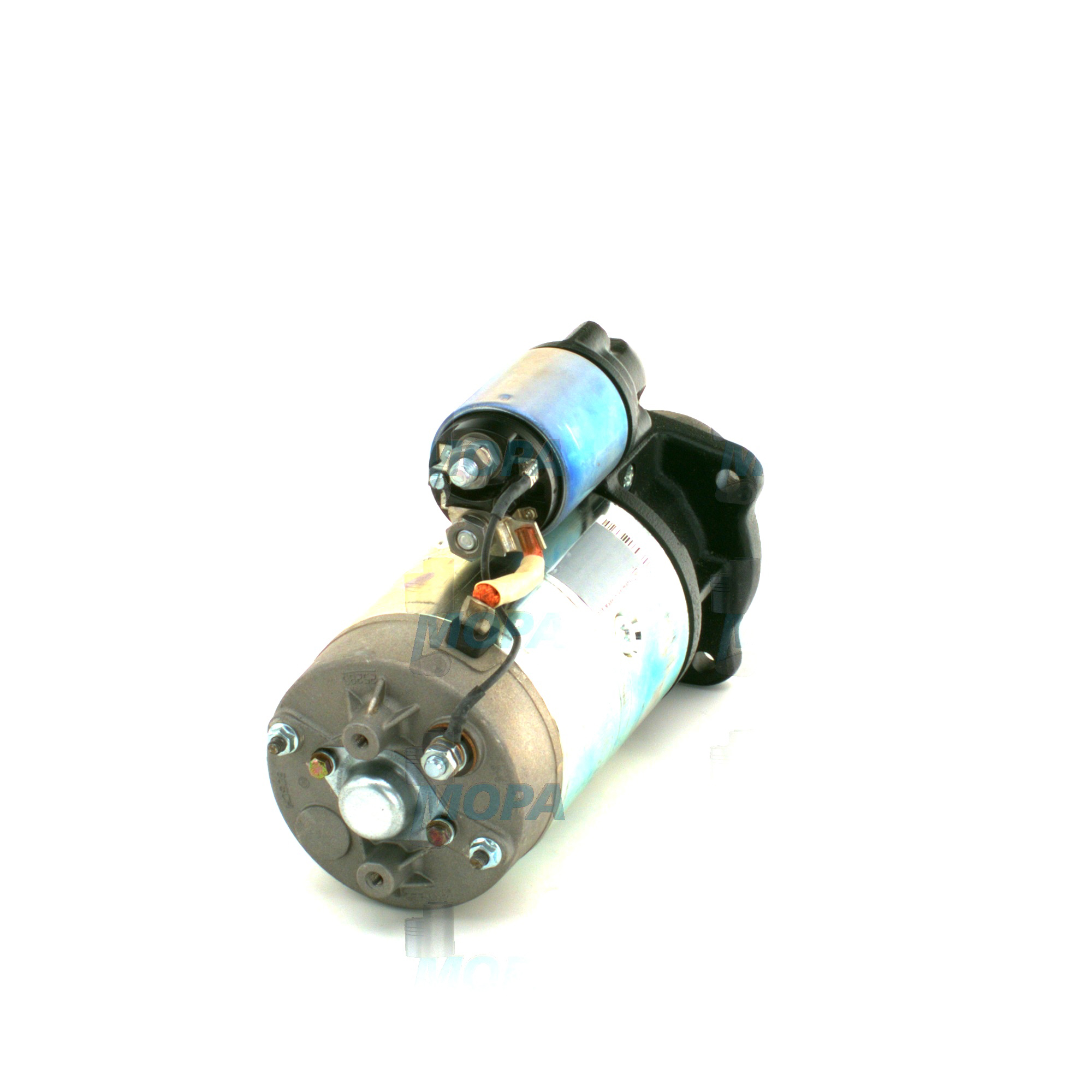

MOPA is a reliable partner for OEM spare parts suitable for BF6L913C. With technical know‑how and a focused product range, MOPA supports purchasers and technical managers in selecting the right components—from injection equipment and turbocharger service kits to cooling airflow parts and instrumentation aligned to BF6L913C specifications. The result is a parts supply that aligns with maintenance schedules, enables efficient overhauls, and helps extend engine service life in both marine and stationary roles.

How OEM spare parts suitable for BF6L913C protect your investment

Running a BF6L913C Deutz marine engine on components built for its exact tolerances means fewer reworks and better uptime. It maintains the calibrated relationship between fuel delivery, boost pressure, and thermal balance, which is vital for steady‑state generator duties and cyclic loads on deck machinery. By standardizing on OEM spare parts suitable for BF6L913C, operators gain consistent performance baselines for trending, making it easier to plan overhauls, manage inventory, and control lifecycle costs.

Conclusion: BF6L913C diesel engine and dependable OEM spare parts supply

The BF6L913C is a durable, efficient Deutz 913‑series diesel engine designed for demanding marine and stationary applications. Its air‑cooled architecture, mechanical simplicity, and modular construction make it a favorite among operators who prize reliability and serviceability.

MOPA supplies OEM spare parts suitable for BF6L913C to help you maintain performance, reliability, and long service life across your fleet or facility. For purchasers and technical decision‑makers, this combination of a proven engine platform and a dependable parts partner translates into confident operation and controlled operating costs.