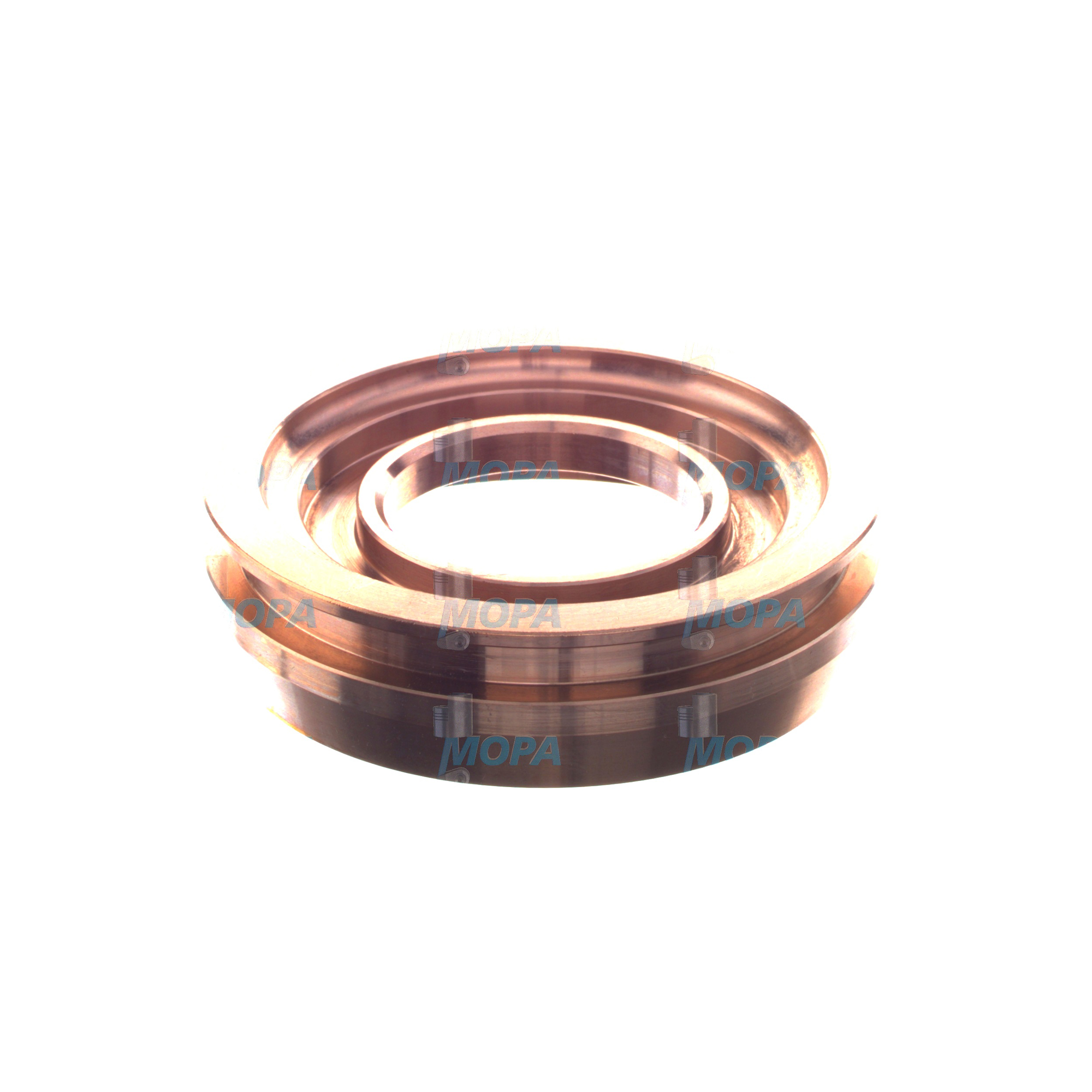

SEAL CARRIER

SEAL CARRIER applications for Gaskets in diesel and marine engines

Gaskets form the critical sealing layer between static engine components, preventing the transfer of fluids, gases, and combustion pressures where they do not belong. As precision-engineered consumables, gaskets are indispensable across cylinder heads, exhaust systems, charge-air paths, turbo interfaces, pumps, covers, and auxiliary equipment. In propulsion and power-generation duty, the integrity of these seals directly impacts engine performance, emissions stability, and uptime. Equally important, interfaces around a SEAL CARRIER—such as housings for rotating shafts, timing covers, or auxiliary drives—depend on correct gasket selection and fit to maintain leak-tight, durable joints.

For purchasers, shipowners, and technical decision-makers, specifying the right gasket technology means stable compression, minimal blow-by, controlled thermal movement, and predictable maintenance intervals. This article outlines how modern gasket solutions work, why they matter in heavy-duty diesel and gas engines, and how OEM spare parts suitable for gaskets safeguard reliability and lifecycle cost—especially at interfaces that include a SEAL CARRIER in a marine engine or diesel engine package.

Technical function of Gaskets with SEAL CARRIER interfaces

Gaskets create a conformal barrier between mating flanges. Under bolt preload, the material flows microscopically to fill asperities in the surface finish, establishing a uniform gasket seating stress. In a cylinder head joint, multi-layer steel (MLS) or graphite-laminate gaskets must withstand high combustion pressures, thermal cycling, and micro-movement. In exhaust and turbocharger connections, high-temperature composites resist oxidation and flange distortion. Around oil and coolant circuits, elastomeric or PTFE-based gaskets control low-pressure leakage, chemical attack, and creep relaxation.

Where a SEAL CARRIER meets a housing or cover, the gasket stabilizes the joint so the radial or mechanical seal inside the carrier can operate under controlled runout and contact pressure. In diesel engine applications, a misaligned carrier or inadequate gasket compression can cause shaft leakage, oil aeration, and accelerated wear of the lip or mechanical seal. In marine engine environments, where vibration, torsional pulses, and hull-borne stresses are significant, the gasket-carrier interface must maintain crush and thickness under variable loads. Correct gasket selection preserves the geometry that the SEAL CARRIER OEM parts are designed to assume, protecting both sealing performance and bearing life.

Material science is central to gasket performance. MLS stacks manage head lift with spring steel layers and embossed sealing beads. Expanded graphite offers resilience at high temperatures and resists thermal shock. PTFE and FKM-based solutions address aggressive fuels, coolants, and oils. Key parameters include flange flatness and roughness (Ra), bolt preload and pattern, thermal expansion mismatch, and relaxation over time. Correctly specified, gaskets deliver consistent clamping force, minimize micro-leakage, and reduce the risk of fretting at the interface—including housings that support a SEAL CARRIER in diesel engine auxiliary drives.

Key characteristics and advantages of Gaskets

· High sealing efficiency under dynamic thermal cycles

· Material options for heat, pressure, and chemical exposure

· Predictable compression and recovery for stable preload

· Dimensional accuracy for tight tolerances and groove fits

· Compatibility with SEAL CARRIER housings and covers

· Reduced blow-by and emissions drift over service life

· Lower risk of fluid cross-contamination and dilution

· Proven performance in large-bore marine engine duty

Importance for engine operation and service life

Aging or damaged gaskets jeopardize the entire engine system. Loss of cylinder sealing leads to reduced compression, power imbalance, and increased specific fuel consumption. Coolant-to-oil leakage causes lubrication failure, bearing distress, and varnish formation. Exhaust leaks before the turbo reduce boost, elevate temperatures, and compromise emissions margins. At a SEAL CARRIER interface, an out-of-spec gasket thickness or degraded material can alter carrier alignment, increasing seal wear, leakage rates, and the risk of contamination entering the bearing space.

In continuous-duty marine applications, these failures often translate into unplanned downtime, emergency port calls, and elevated total cost of ownership. Moreover, persistent leakage can trigger corrosion of adjacent components and accelerate flange distortion, complicating subsequent overhauls. Proactive replacement with correctly engineered gaskets maintains stable bolt load, protects flange surfaces, and keeps the joint geometry that SEAL CARRIER diesel engine assemblies require to function reliably across long maintenance intervals.

Advantages of OEM spare parts suitable for Gaskets

Choosing OEM spare parts suitable for gaskets ensures dimensional fidelity, material specifications, and controlled compression behavior that match the engine designer’s sealing strategy. This precision matters at high-stress joints and at interfaces that include a SEAL CARRIER marine engine housing or timing cover.

With OEM spare parts suitable for gaskets, purchasers gain traceable materials, consistent bead geometry in MLS designs, and validated thickness and hardness ranges. The result is predictable bolt torque-to-crush relationships, reduced rework during overhauls, and confidence in emissions and performance stability after reassembly. Correctly matched gasket kits coordinate with mating fasteners and surface finishes, reducing the risk of creep relaxation, flange fretting, or blow-by. Over the lifecycle, this translates into fewer leaks, longer service intervals, and tighter control of maintenance budgets—without compromising safety or regulatory compliance.

For assemblies where the SEAL CARRIER OEM parts must maintain strict alignment, the right gasket tolerances preserve seal contact pressure and minimize runout-induced wear. This is especially important in high-load auxiliary drives, gear covers, and pump housings on diesel and gas engines operating around the clock.

MOPA: fast, reliable supply of OEM spare parts for Gaskets and SEAL CARRIER interfaces

MOPA supports operators with rapid sourcing and delivery of OEM spare parts suitable for gaskets across diesel and gas engines, including configurations that mate with a SEAL CARRIER. Customers benefit from responsive lead times, rigorous quality controls, and secure transactions that protect project schedules. Our team cross-references part numbers, advises on material selections for specific fuels and coolants, and aligns gasket specifications with class and engine-builder requirements. From head sets to turbo and auxiliary sealing kits, MOPA streamlines procurement so your maintenance teams can execute overhauls efficiently and confidently.

Conclusion

Gaskets are foundational to engine reliability, sealing performance, and operational efficiency—particularly at precision interfaces that include a SEAL CARRIER in marine and diesel engines. Specifying OEM spare parts suitable for gaskets provides the material quality, dimensional accuracy, and consistency needed to protect performance, extend service life, and control total cost of ownership.

Trust in Our OEM Spare PartsDiscover our product, the seal carrier with the comparison number 02420936. This seal carrier belongs to the article group gaskets and offers an excellent solution for optimal sealing in engines. Its innovative design ensures that engines do not develop unwanted leakage during operation.Suitable for Deutz Engines – Quality That ConvinceThe seal carrier is suitable for Deutz engines and provides long-lasting performance due to its high precision. Weighing only 0.04 kg, it supports an ideal power-to-weight ratio while its processing as an OEM spare part meets the highest standards. Trust in this product to keep your engines operating efficiently and reliably.

Robust Seal Carrier – OEM Replacement Part for EnginesDiscover our Seal Carrier with the comparison number 5800110558. This product is an essential OEM replacement part specifically designed to provide an optimal sealing solution for your MTU engines. Our Seal Carrier is compatible with a variety of engine models from the series 1163 and 956, including types 16V1163TB83, 20V1163, 20V1163TB82, 20V1163TB93, and 20V956TB92.Precise Fit for MTU EnginesThanks to its specially developed shape and sturdy materials, this Seal Carrier ensures a precise fit and durability. This product weighs only 0.112 kg and has a length and width of 36.7 cm and a height of 5.7 cm. Optimize the operation of your engines with this performance-driven replacement part that offers an attractive solution for commercial applications.

Quality Seal Carrier for Optimal Engine SystemsUse the seal carrier with the comparison number 5842030058, an essential OEM spare part designed specifically for efficient sealing in engines. This product is suitable for the renowned MTU engines and brings reliability to your applications. The precise pulls and materials ensure performance and a long lifespan.

Premium Spare Part: Seal Carrier for EnginesDiscover our seal carrier, an OEM spare part with the comparison number 9423530117. This product impresses with its perfect fit, suitable for Mercedes engines. Rely on acquired expertise that benefits your choice.Important Features of the ProductThe seal carrier belongs to the article group gaskets and is essential for optimal engine operation. With the comparison number 9423530117, you are opting for capable OEM spare parts that stand out for their quality.

Versatile Seal Carrier for Various ApplicationsDiscover our OEM replacement part, the seal carrier with the comparison number 5842000160. This product is specifically designed to ensure reliable sealing function in your engines. The seal carrier offers you quality and efficiency, making it indispensable for any application.

Seal Carrier with Comparison Number 8200160158Discover our seal carrier with the comparison number 8200160158, suitable for MTU engines. This product meets exactly the requirements you expect from OEM spare parts. Thanks to precise manufacturing, it ensures solid sealing and durability.

Premium Seal Carrier for MTU Engines for Optimal PerformanceDiscover our product, the seal carrier with the reference number 5800110258. This OEM replacement part is suitable for MTU engines in the 1163 series and provides an excellent solution for your needs. Optimal performance and functionality are our top priorities.

Seal carrier with comparison number 5582531258The seal carrier with the comparison number 5582531258 is an indispensable spare part that has been specifically designed to ensure the performance and sealing of your products. This product is known for its excellent fit, allowing for smooth operation and a long service life.Advantages of spare partsUnlike aftermarket products, spare parts like this seal carrier offer maximum reliability. They are suitable for specific model series, just as the comparison number 5582531258 indicates. By using OEM parts, you eliminate the risk of complications associated with non-original components.

Quality for Your EnginesDiscover our seal carrier, comparison number 5592030158. This replacement part ensures a perfectly coordinated seal and offers all the important characteristics you can expect from a component of this type. Ideal for applications in marine and stationary technology, this product delivers the necessary process efficiency.Suitable for Series 331 and 12V331TC92The seal carrier is suitable for the series 331 and the engine type 12V331TC92. Many industrial applications require functionally oriented designs that ensure high efficiency and minimized downtime. Our products are well suited to operate a safe and functional system.

Perfect Seal Carrier for Reliable ApplicationsDiscover the seal carrier (comparison number: 03361772), an essential product that helps maintain the integrity of your suitable for MWM & Deutz engines. It belongs to the gasket product group and is designed to efficiently prevent leaks, ensuring that engines operate reliably and at optimal performance – suitable for demanding applications.

Reliable Seal Carrier for Marine OptimizationThe seal carrier with the comparison number 3581430 is one of the important OEM replacement parts you need for your machines. This product ensures that the sealing quality of the engines is maintained at the highest level. The seal carrier is designed to fit Volvo/Volvo Penta engines and effectively helps to avoid sealing problems. Trust in quality that convinces!Tailored Solution for Volvo/Volvo PentaWeighing 0.088 kg, the seal carrier is functionally designed. It is specifically made for Volvo/Volvo Penta engines, making it ideally suited to maximize the performance of your systems. This gasket solution meets the highest standards for engines used in marine and stationary applications, ensuring that your machines operate efficiently.

Precise Seal Carrier – Comparison Number 5841880058The seal carrier with the comparison number 5841880058 is an important OEM replacement part designed to ensure top performance in various applications. This seal carrier is specifically suitable and compatible with a range of MTU engines, particularly fitting for the series 1163 and the engine type 20V1163TB93. Weighing only 0.229 kg and featuring compact dimensions (8 cm x 8 cm x 2.2 cm), it allows for effortless handling and fits seamlessly into existing systems.

Precise Replacement Part: Seal CarrierDiscover our seal carrier, comparison number 03046340, an essential OEM replacement part specifically designed for MWM & Deutz engines. This product belongs to the category of gaskets and impresses with its exceptional workmanship. Weighing 2.463 kg, our seal carriers are ideal for demanding applications.

Robust Seal Carrier: Comparison Number 5590310058Discover our popular seal carrier with the comparison number 5590310058. This product belongs to the category of gaskets and provides a reliable sealing for your systems. With years of experience in spare parts, we understand how important precise components are for the efficient operation of engines.

Effective Seal Carrier for MTU EnginesDiscover the seal carrier with the reference number X53620700004, compatible with MTU engines. This pure OEM replacement part ensures excellent sealing and significantly extends the lifespan of your engines.

Seal carrier as a fundamental component suitable for MTU enginesDiscover our seal carrier, a top-quality OEM replacement part with the comparison number 5272010258. This product has been designed to meet the specific requirements of engines. Weighing 4 kg, the seal carrier provides the necessary stability and efficiency. It is the ideal solution for those who value OEM quality standards.

High-performance Seal Carrier for MTU EnginesDiscover our long-term reliable seal carrier with the comparison number 5272010358 – an essential OEM spare part for the efficient use of your MTU engines. This product weighs only 3.9 kg and impresses with its unique precision, which works reliably even under the most demanding conditions. With this seal carrier, you ensure the tightness of your engines and minimize the risk of leaks.

Precise Spare Part Solution: Seal CarrierDiscover our Seal Carrier, comparison number 03365781, the ideal product suitable for Deutz engines. This OEM spare part is specifically designed to meet the diverse requirements in marine and stationary applications as well as for locomotives. Robust products like our Seal Carrier are essential to ensure the performance of your engines.

SEAL CARRIER with the comparison number Z=G4 07562B suitable for MTU engines

Reliable Performance with Seal CarrierDiscover our innovative product, the Seal Carrier with the comparison number 5842030158. This powerful seal carrier is the key component for efficient engines. The optimal fit of the replacement part ensures reliable performance and a long service life. Save costs with this replacement part, specifically designed for maintenance and service measures on engines.

SEAL CARRIER with the comparison number 85000011723 suitable for MAN D engines