IMPELLER Pumps, Parts and Accessories for Marine and Industrial Engines

Pumps, parts and accessories form the circulatory system of any engine room. This article category covers complete pump assemblies as well as precision components such as IMPELLERs, seals, bearings, wear rings, shafts, casings, gaskets and the accessories that keep them aligned, monitored and protected. In marine engine and power generation environments, pumps move cooling water, lubricating oil and fuel with stable pressure and flow, securing thermal balance, friction control and safe operation. Without robust pumps and correctly matched parts, even the best diesel engine or gas engine cannot deliver performance or uptime.

From seawater cooling pumps and jacket-water centrifugal pumps to lube oil gear pumps and fuel transfer units, each element is engineered to withstand heat, vibration, contaminants and corrosive media. Selecting the correct IMPELLER, seal set and accessory kit is therefore not a procurement detail—it is a core reliability decision that impacts efficiency, emissions, and the service life of connected equipment.

Technical function of Pumps, Parts and Accessories with IMPELLER in marine and diesel engines

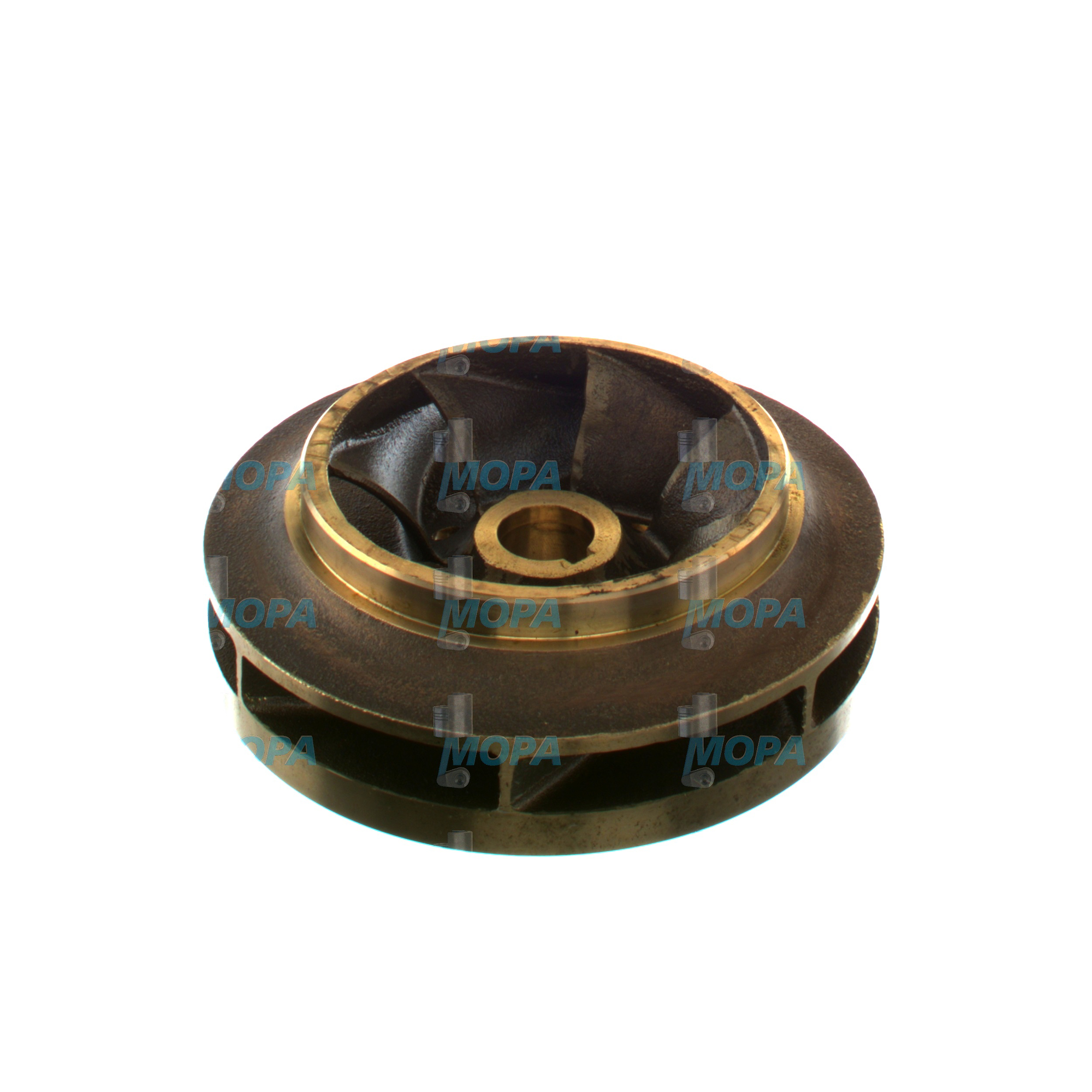

Pumps convert shaft power into controlled flow and pressure. In cooling systems, a centrifugal pump with a metal IMPELLER generates head to circulate jacket water through the block, turbocharger and heat exchangers. For raw-water circuits on a marine engine, a flexible IMPELLER pump draws seawater, self-primes, and maintains suction even at low speeds. Lube oil pumps (gear or screw types) build the hydrodynamic film that separates bearings and journals, while fuel feed and transfer pumps stabilize supply pressure, protecting injection equipment.

The IMPELLER is central to this conversion. In a centrifugal design, vane geometry, outlet angle and clearance define efficiency, NPSH margin and cavitation resistance. In flexible IMPELLER pumps, elastomer hardness, vane count and hub design determine self-priming capability, flow stability and abrasion tolerance. IMPELLER OEM parts manufactured to engine-maker specifications maintain the exact hydraulic profile, ensuring predictable duty points and keeping temperatures, oil pressure and exhaust values inside design limits.

How an IMPELLER drives cooling performance

An IMPELLER for a marine engine raw-water pump must tolerate brackish water, shells and sand. Bronze or stainless housings combined with nitrile or neoprene vanes resist corrosion and wear. For a diesel engine jacket-water pump, a dynamically balanced metal IMPELLER minimizes vibration and shaft loading, preserving seal faces and bearing life. Correct clearances prevent recirculation and maintain volumetric efficiency, while the right accessory—strainers, check valves, couplings—protects the pump from debris, reverse flow and misalignment.

- · Stable flow at rated RPM across cooling, lube and fuel circuits.

- · Self-priming capability with flexible IMPELLER seawater pumps.

- · Materials matched to media: bronze, duplex stainless, nitrile, EPDM.

- · Precision seals and shaft sleeves for leak-tight operation.

- · Balanced IMPELLERs reduce vibration and bearing stress.

- · Optimized clearances sustain efficiency and head.

- · Accessories (strainers, couplings, gauges) protect and monitor the system.

Why IMPELLER pumps, parts and accessories are critical for engine reliability

Engine dependability hinges on controlled temperatures, lubrication pressure and fuel delivery. If an IMPELLER wears or deforms, flow drops and raw-water intake may lose prime, leading to rapid overheating, high exhaust temperatures and potential head-gasket or turbocharger damage. Eroded wear rings or incorrect clearances increase recirculation losses and energy consumption. Seal degradation allows media leakage, contamination of bilges, and air ingress that destabilizes pump performance. Bearing wear and misaligned couplings elevate vibration, accelerating failure across connected components.

Conversely, when pumps and associated parts are kept within their design tolerances, jacket-water deltas remain stable, oil pressure recovers quickly after start, and injectors receive clean, consistent fuel. That stability extends engine service life, reduces unplanned stops, and preserves safety margins in confined engine rooms and at sea.

Advantages of OEM spare parts suitable for Pumps, Parts and Accessories

IMPELLER OEM parts: fit, materials, performance

Choosing OEM spare parts suitable for pumps, parts and accessories delivers measurable lifecycle benefits. Dimensional accuracy ensures that an IMPELLER seats correctly on the shaft, that wear rings restore factory clearances, and that mechanical seals match face materials and spring loads. Material parity—such as the specified elastomer for a flexible IMPELLER or the alloy grade for a centrifugal IMPELLER—preserves chemical compatibility and heat resistance, particularly in seawater and high-temperature oil circuits.

Procurement teams also benefit from predictable performance data and maintenance intervals. With OEM parts, hydraulic curves, expected head and efficiency values align with the engine maker’s documentation, enabling precise planning of overhauls and spares inventory. Installation time shortens because parts fit without rework, and the risk of collateral damage from poor tolerances drops, protecting both budget and uptime.

Key outcomes when using OEM spare parts suitable for this category include consistent pump efficiency, lower vibration and noise, reduced leakage, and stable operating temperatures and pressures. Over the life of a diesel engine or gas engine package, that translates to fewer interventions, lower fuel consumption due to optimized cooling, and extended asset life.

MOPA as your partner for OEM Pumps, Parts and Accessories

MOPA is an experienced, reliable partner for OEM spare parts across pumps, parts and accessories, including every critical IMPELLER type used in marine engine, diesel engine and gas engine applications. We prioritize speed through efficient sourcing and logistics, quality through traceable supply and rigorous inspection, and security through compliant documentation and safe packing for global shipments. Whether you need a flexible IMPELLER and seal kit for a seawater pump, a balanced centrifugal IMPELLER for a high-capacity jacket-water pump, or complete accessory sets—strainers, couplings, gauges—MOPA supports rapid turnaround and consistent technical outcomes.

Conclusion: Pumps, Parts and Accessories and IMPELLER essentials

Pumps, parts and accessories keep engines within safe thermal and lubrication limits, and the IMPELLER is the heart of that hydraulic performance. Selecting OEM spare parts suitable for this category safeguards fit, materials and efficiency, protecting reliability, service life and budget.

With the right IMPELLER and matched components on board—and a responsive partner like MOPA—your equipment operates at design performance on every voyage and through every duty cycle.