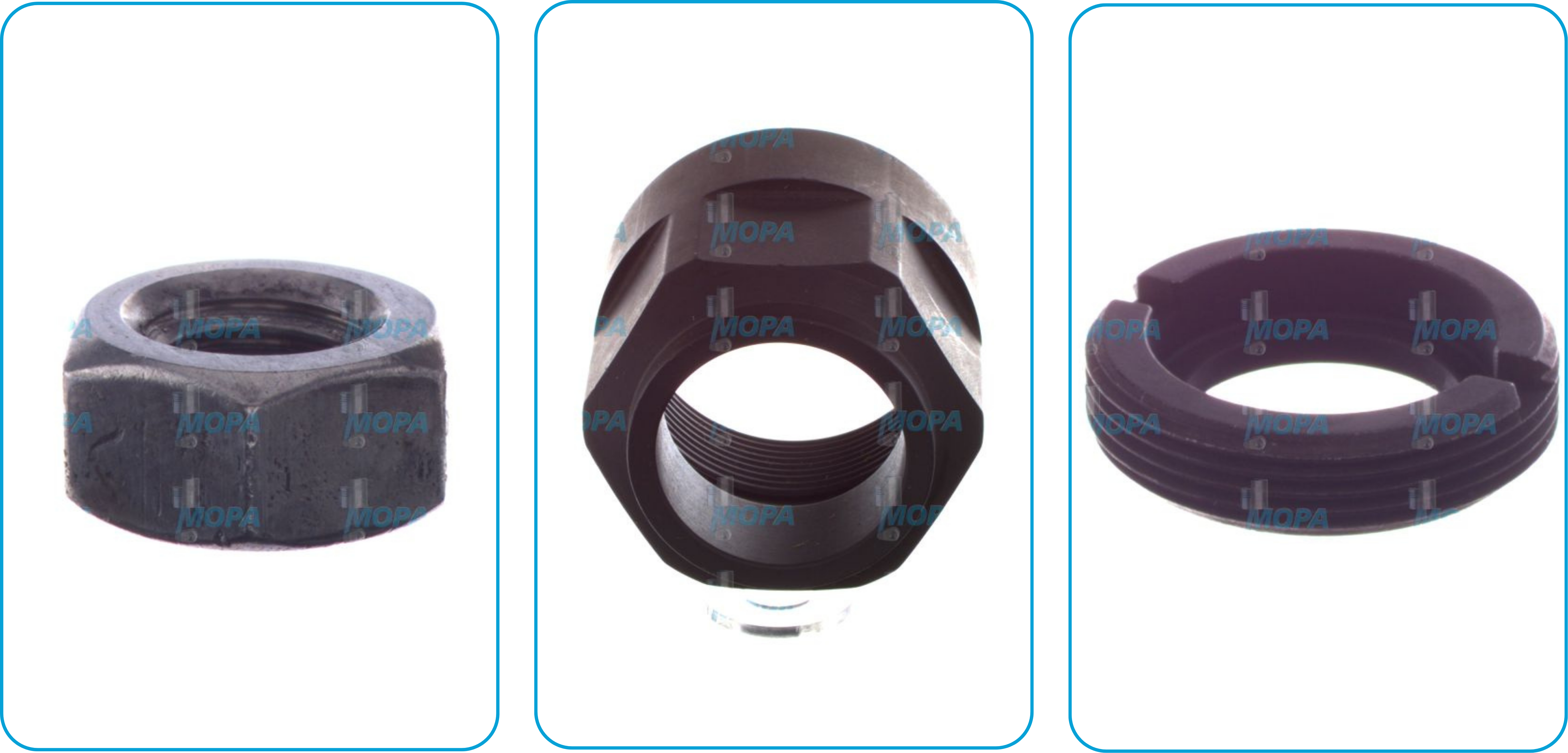

Screw nuts – secure fastening for engine systems

Screw nuts are fundamental components for assembling and securing mechanical structures, especially in engine and industrial systems. Whether used in combustion engines, marine machinery or stationary equipment – high-quality screw nuts ensure reliable fastening under high loads, vibrations and temperature fluctuations. They are essential for safety, serviceability and long-term performance.

Choose from following:

Function and advantages

Screw nuts work in combination with bolts or studs to create strong, threaded connections. In engine systems, a proper engine nut or motor nut must withstand dynamic forces and temperature-related expansion. Key benefits include:

- Secure locking of mechanical components under stress

- Resistance to loosening under vibration

- Easy assembly and disassembly for maintenance

In high-precision systems, mechanical nuts often feature locking mechanisms, flange bases or specialized coatings to enhance grip and corrosion resistance.

Applications and types

Engine nuts are used to fasten cylinder heads, manifolds, brackets and rotating assemblies. Motor nuts are common in alternators, starters, pumps and other auxiliary components. Depending on the application, mechanic nuts can be hex nuts, locknuts, self-locking nuts or high-temperature nuts.

For industrial and marine use, mechanical nuts are often made of stainless steel or alloyed materials to withstand corrosion, vibration and thermal cycles. Our range includes all standard types and sizes suitable for MTU, MAN, Volvo Penta, Deutz and MWM engines.

Availability and sourcing

We stock a wide selection of screw nuts and related fasteners for engines, industrial equipment and marine applications. As experienced screws and nuts suppliers, we provide OEM-quality with fast delivery, technical support and high availability – ideal for overhauls, repairs or production sourcing.

FAQ

What are screw nuts used for in engines?

Screw nuts in engines are used to secure critical components such as cylinder heads, exhaust systems, brackets and rotating parts. They must withstand heat, vibration and mechanical stress without loosening.

What is the difference between mechanical nuts and mechanic nuts?

“Mechanical nuts” refers to all technical fasteners used in machines, while “mechanic nuts” is a more informal term often used in workshop contexts. Both describe the same parts but are used in different settings.

Where can I buy engine nuts and motor nuts?

Engine nuts and motor nuts are available from specialized screws and nuts suppliers like us. We offer a wide range of standard and special fasteners for diesel and gas engines, with OEM compatibility and fast shipping.