Pipe connections – secure fluid routing in engine systems

Pipe connections are essential components in engines and technical systems, providing reliable and leak-proof joining of pipelines. Whether in marine diesel engines, auxiliary systems or industrial plants, high-quality pipe connections ensure that fluids such as fuel, oil, coolant or air flow safely and efficiently. In marine applications, they must also withstand corrosion, vibration and pressure fluctuations.

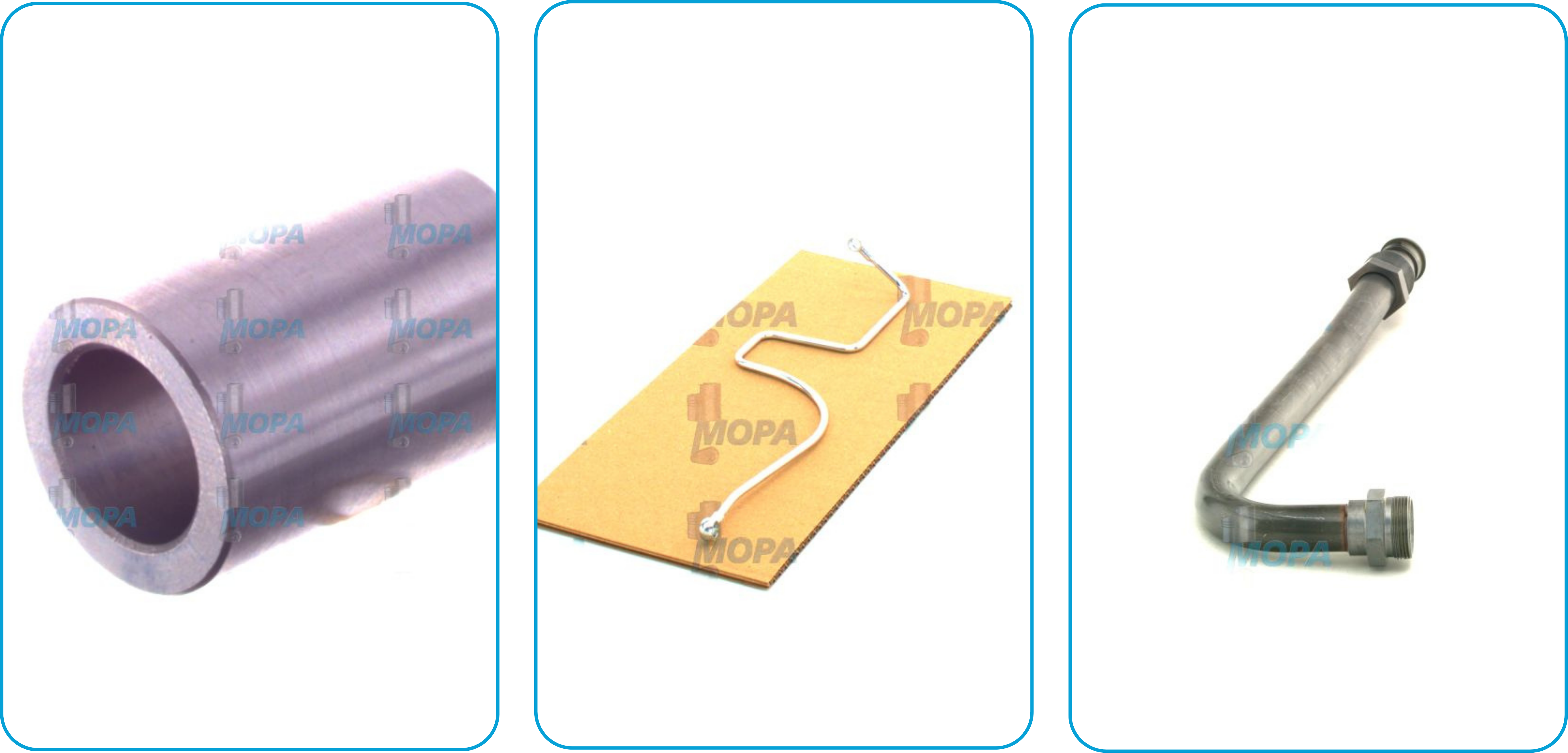

Choose from following:

Function and advantages

Pipe connections link individual sections of piping or flexible hoses to form a continuous and sealed flow path. Depending on the medium and application, connections must be pressure-resistant, temperature-stable and vibration-proof. Advantages include:

- Leak-proof operation under mechanical stress

- Quick installation and easy maintenance access

- Compatibility with various pipe materials and sizes

Marine engines require especially robust and corrosion-resistant pipe connections to ensure system reliability over long operational cycles at sea.

Types and materials

Common types of pipe connections include:

- Threaded connectors (e.g. BSP, NPT)

- Flanged joints

- Compression fittings

- Clamp or quick-connect systems

Materials range from stainless steel and brass to high-performance polymers, depending on the fluid type and environmental exposure. All components must meet high tolerance and sealing standards, particularly in high-pressure engine systems.

Applications and compatibility

Pipe connections are used in fuel lines, oil circuits, cooling systems and compressed air networks. In marine engines, these connections must resist saltwater, high humidity and temperature shifts. Our product range includes connections suitable for MTU, MAN, Volvo Penta, MWM and Deutz engines – compatible with OEM specifications and ready for immediate use.

FAQ

What are pipe connections used for?

Pipe connections are used to join pipe sections or hoses in fluid-carrying systems. They ensure leak-proof, pressure-tight operation and allow for disassembly during maintenance.

How do I choose the right pipe connection?

The right pipe connection depends on pressure level, medium (oil, fuel, air, etc.), pipe material and environmental conditions. Factors such as thread type, sealing method and corrosion resistance are critical.

Are pipe connections in marine engines different?

Yes. Marine pipe connections are built for high resistance to corrosion, vibration and temperature changes. They are typically made of stainless steel or special alloys and meet classification society standards.