Locking parts – secure fastening for engines and machinery

Locking parts are essential for ensuring that fasteners and mechanical assemblies remain secure under load, vibration and thermal stress. In engines, turbines, marine systems and industrial equipment, locking parts prevent critical components from loosening during operation – a key factor for safety, durability and system integrity.

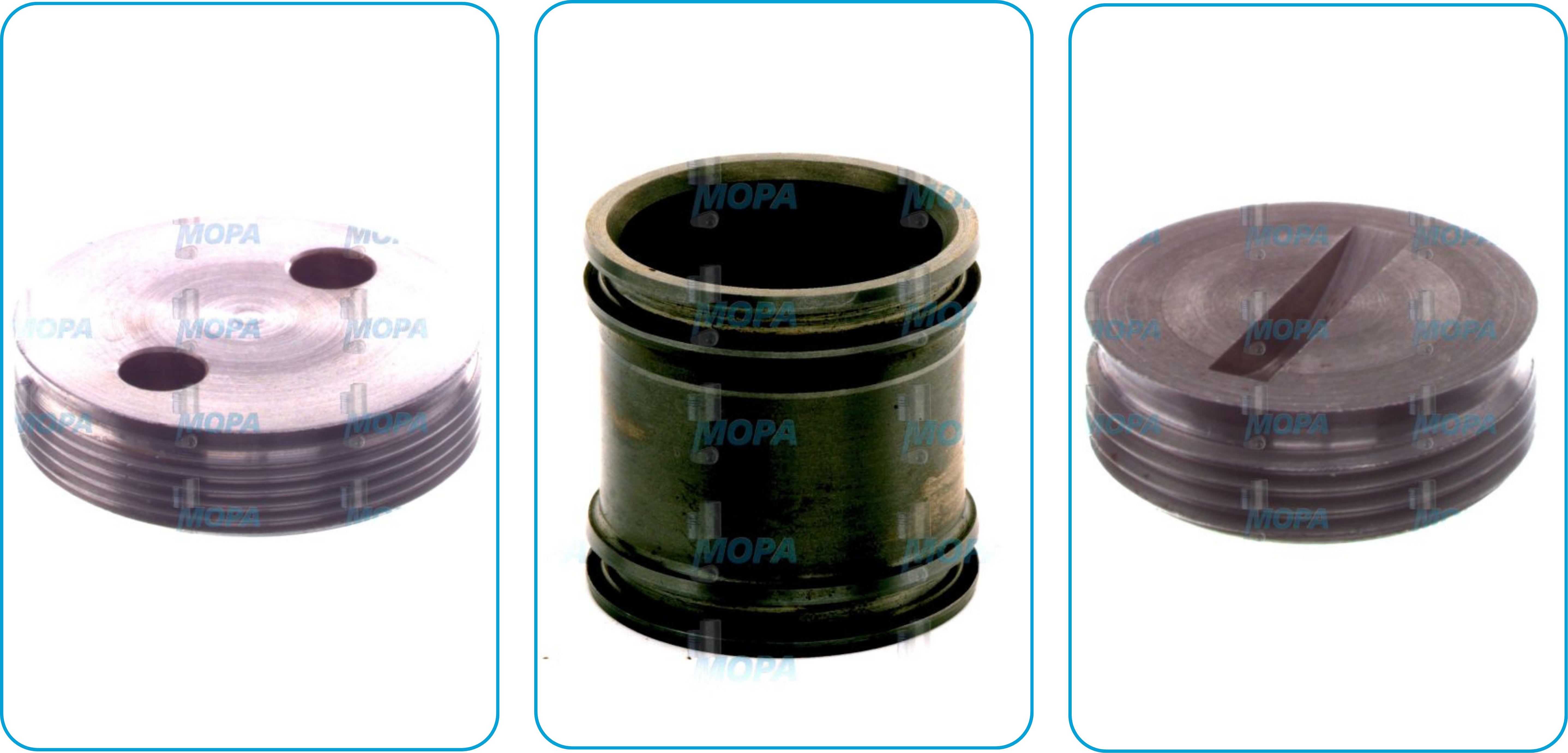

Choose from following:

Function and benefits

Locking parts are used to fix bolts, nuts, shafts or rotating elements in place. They protect against unintentional movement or unscrewing due to vibration, pressure changes or torque fluctuations. Benefits include:

- Secure hold of mechanical connections

- Increased system safety and reduced failure risk

- Improved service intervals and reliability

In high-performance diesel engines or marine drives, locking systems are critical to prevent loosening of vital components under continuous vibration and extreme temperatures.

Types of locking parts

Our range of locking parts includes:

- Locking washers (e.g. serrated, tab or spring washers)

- Locknuts and self-locking nuts

- Locking clips and retaining rings

- Split pins, cotter pins and safety wires

These components are available in materials such as spring steel, stainless steel, and corrosion-resistant alloys – ideal for use in marine environments or thermal cycling conditions.

Applications in marine and industrial systems

Locking parts are used in crankshaft assemblies, valve trains, coupling flanges, pump mounts and exhaust systems. In maritime settings, reliability under constant vibration and salt exposure is key. We offer OEM-locking solutions suitable for MTU, MAN, Volvo Penta, Deutz and MWM engines – suitable for both new builds and overhauls.

FAQ

What are locking parts used for?

Locking parts secure mechanical fasteners and rotating elements, preventing loosening due to vibration, pressure or thermal expansion. They are vital in engines and machinery to maintain operational safety and performance.

How do I choose the right locking part?

Selection depends on load, operating temperature, vibration level and component type. In high-stress environments, self-locking nuts or tab washers are often preferred over standard fasteners.

Are locking parts reusable?

Some locking parts like tab washers or safety clips are designed for single use, while others like locknuts or spring washers can be reused if undamaged. Always follow engine manufacturer guidelines for replacements.