Air compression systems – reliable air supply for engines and machinery

Air compression systems are essential for supplying pressurized air in industrial, marine and mechanical environments. Whether for starting engines, controlling valves or powering tools, well-designed air compression systems provide a consistent and efficient source of compressed air. In marine settings, a stable marine air supply is crucial for safe engine operation and onboard system functionality.

Choose from following:

Function and benefits

Air supply systems work by compressing ambient air and distributing it to various components such as starters, actuators, brake systems or control units. In engines, compressed air is often used for cold starting or cleaning purposes. Key benefits of high-performance air compression setups include:

- Reliable air delivery for starting, control and safety systems

- Reduced downtime through consistent pressure management

- Scalable configurations for marine, industrial or mobile use

For marine engines and generators, a redundant marine air supply system ensures that compressed air is available even under emergency or overload conditions.

Applications and configurations

Air compression systems are used in ships, offshore platforms, power plants and large machinery. Common configurations include piston compressors, screw compressors and complete skid-mounted units. Compressed air may be stored in high-pressure tanks and distributed through integrated air supply systems with dryers, filters and pressure regulators.

Some advanced applications include the use of compressed air engines as auxiliary power units or environmentally friendly drive systems. Customers seeking alternatives may look for compressed air engine buy options or even consider experimental setups such as a compressed air boat.

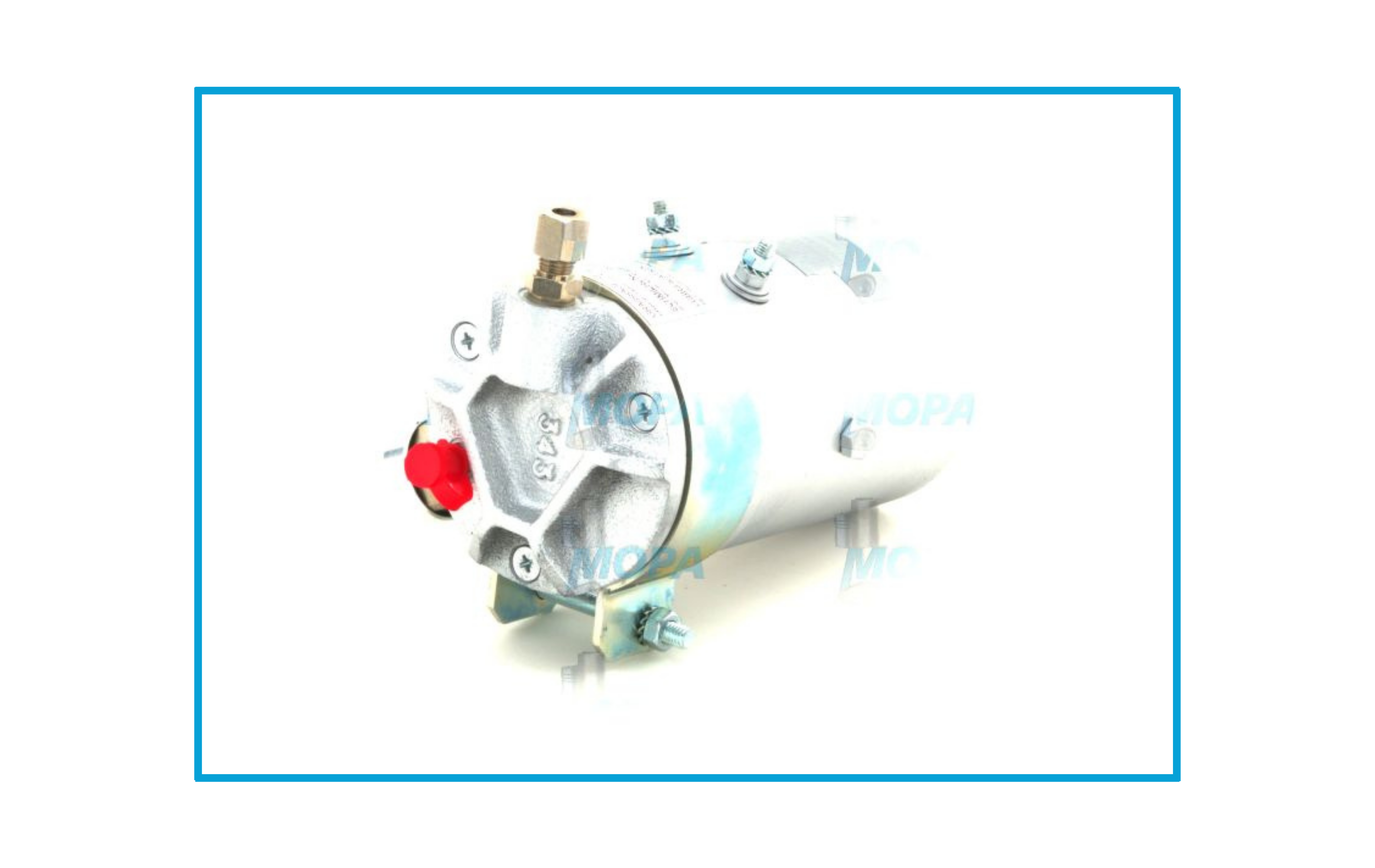

System components and availability

Key components of a complete air compression system include compressors, air receivers, pressure relief valves, filters, control panels and distribution lines. We offer air supply solutions and parts compatible with systems from MAN, MTU, Volvo Penta, Deutz and other major engine platforms – optimized for industrial and marine-grade performance.

FAQ

What are air compression systems used for?

Air compression systems supply compressed air for mechanical, pneumatic and engine-related operations. They are used for engine starting, actuation, tool operation, valve control and cleaning processes.

Can compressed air be used to power a boat?

While rare, some experimental or eco-friendly designs use compressed air propulsion. A compressed air boat uses stored air to drive pistons or turbines. However, range and efficiency are currently limited compared to combustion engines.

How do I choose the right marine air supply system?

The right marine air supply system depends on engine size, start-up frequency, redundancy needs and onboard safety standards. Key factors include tank volume, compressor capacity, moisture control and integration with control systems.