Engine manifolds – efficient flow and pressure control

Engine manifolds are critical components in combustion engines, responsible for directing air, fuel and exhaust gases to and from the engine cylinders. High-quality engine manifolds ensure optimal flow dynamics, pressure distribution and thermal performance. Whether used in stationary generators, industrial machinery or marine engines, they play a key role in power output and fuel efficiency.

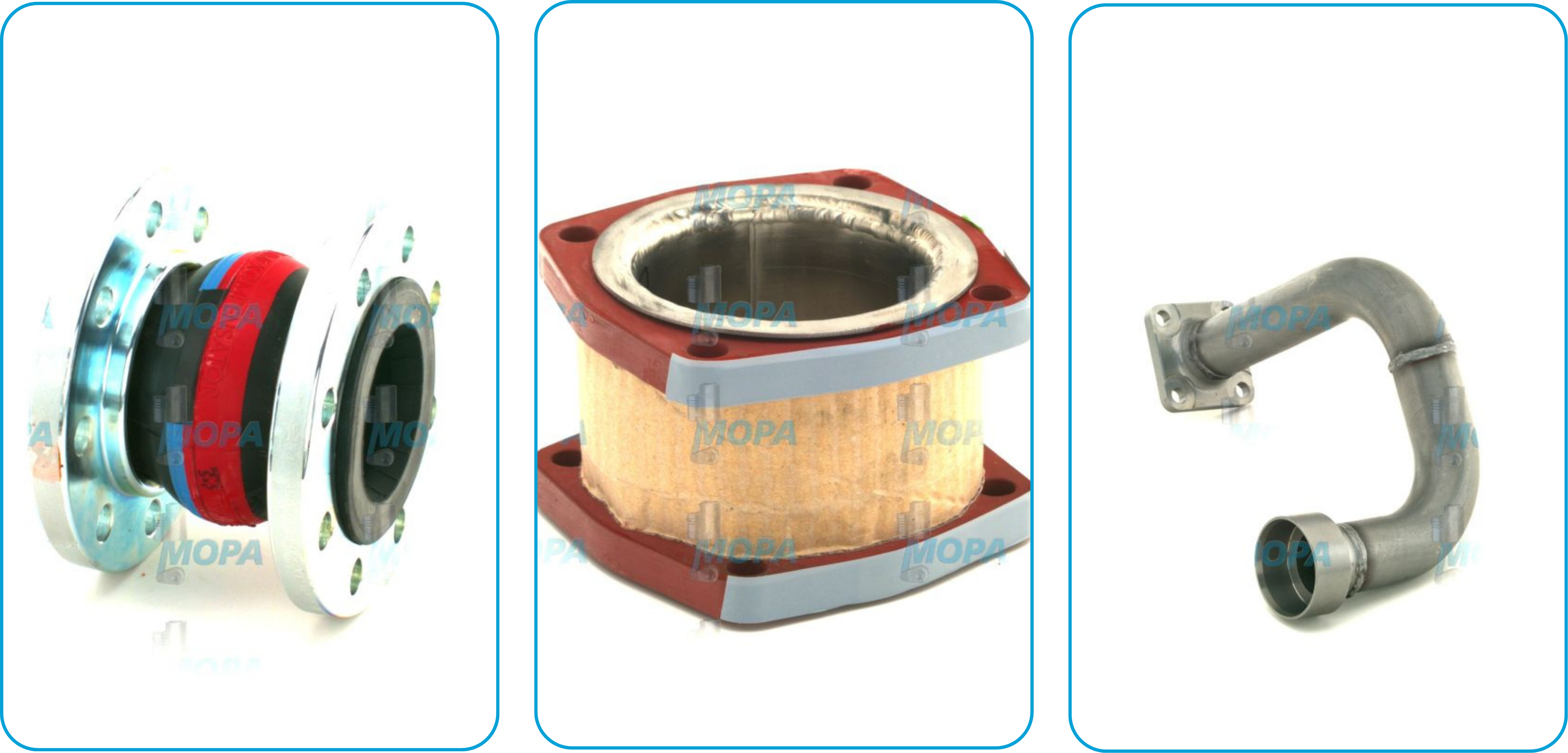

Choose from following:

Function and benefits

There are two main types of engine manifolds: intake and exhaust. The intake manifold supplies air or air-fuel mixture to the cylinders, while the exhaust manifold collects combustion gases and channels them to the exhaust system. Key advantages of optimized engine manifolds include:

- Improved engine breathing and performance

- Balanced pressure distribution across cylinders

- Reduced emissions and heat accumulation

In marine manifolds, materials and design must withstand high humidity, salt exposure and continuous thermal stress – especially in high-load diesel manifolds.

Applications and related components

Diesel manifolds are commonly used in marine propulsion systems, generator sets, and heavy-duty industrial engines. Many systems integrate a compensator to absorb vibration, reduce thermal expansion stress or regulate pressure surges. Compensators in control systems help maintain stability by offsetting dynamic pressure changes caused by load variations or exhaust pulses.

Our product range includes cast iron, stainless steel and composite engine manifolds, suitable for MTU, MAN, Volvo Penta, Deutz and MWM engines – available as new parts or reconditioned replacements.

Durability and replacement

Manifolds are exposed to extreme temperatures, pressure fluctuations and chemical exposure. Over time, cracks, warping or gasket failure may occur. In such cases, replacement is often more cost-effective than repair, especially in high-temperature diesel applications. Marine engines benefit from corrosion-resistant manifold designs and thermal compensator elements to extend service life.

FAQ

What is the engine manifold repair cost?

Repairing an engine manifold can cost anywhere from €200 to over €1,500 depending on the engine size, material, labor and whether the damage involves cracks or sealing surfaces. In marine engines, total replacement is often recommended due to corrosion or thermal fatigue.

What causes manifold failure?

Common causes include thermal expansion, vibration, gasket failure, corrosion (especially in marine environments), and incorrect installation. Diesel manifolds are especially prone to heat-related stress over time.

Can a compensator improve manifold performance?

Yes. A compensator installed in a control or exhaust system can absorb vibration and reduce pressure surges, protecting the manifold and downstream components. It helps balance pressure and extend component life, especially in turbocharged or marine diesel engines.