Motor plates – mounting solutions for engine systems

Motor plates are essential components used to mount, align and stabilize engines and auxiliary units in a wide range of applications. Whether in marine propulsion systems, generator sets or industrial machinery – high-quality motor plates ensure secure positioning and mechanical support under dynamic load. In combination with engine holders and motor flanges, they form the structural basis of reliable engine integration.

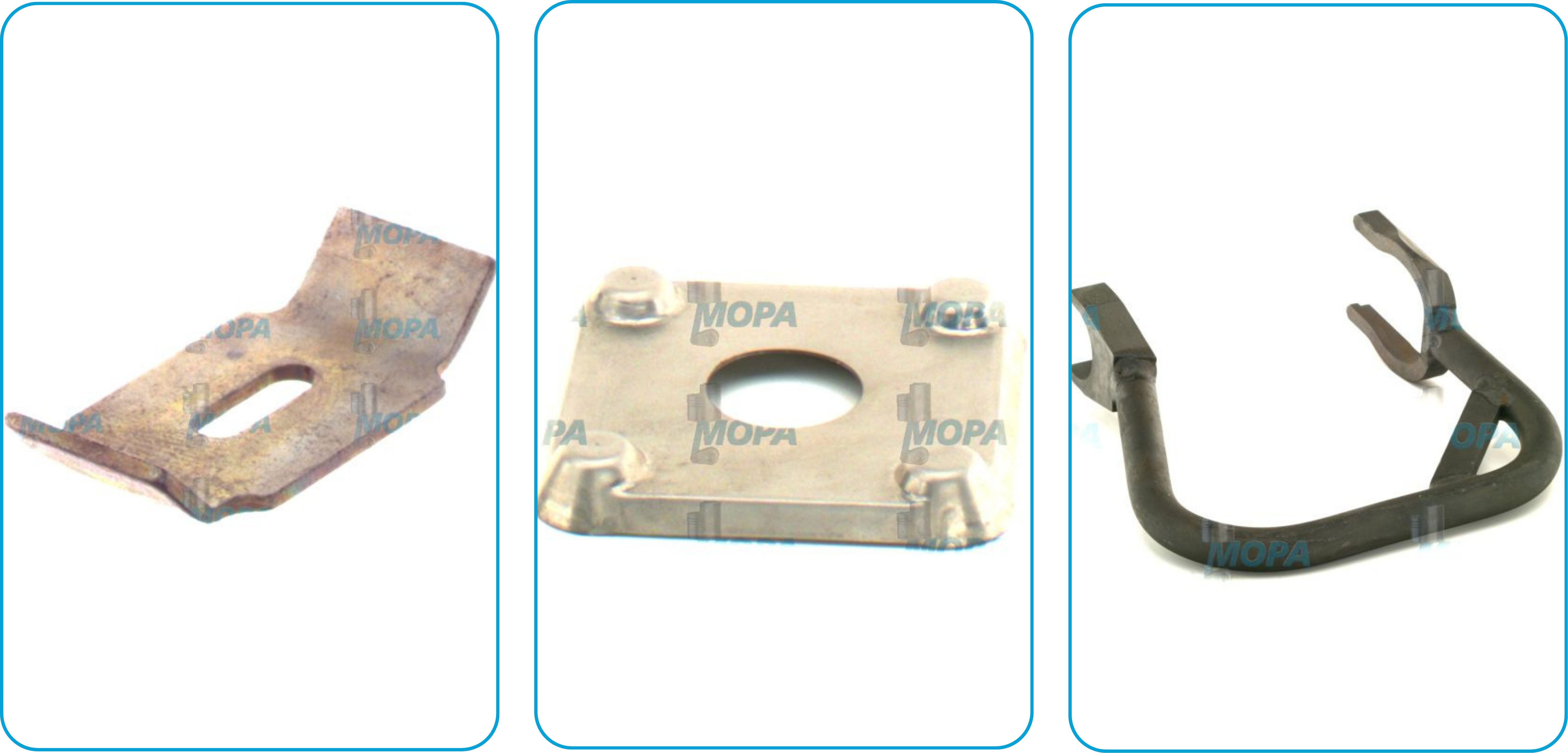

Choose from following:

Function and advantages

A motor plate connects the engine or motor to the base frame or surrounding equipment. Its role is not only mechanical but also functional – enabling alignment, vibration absorption and load distribution. Key benefits include:

- Stable engine mounting under vibration and torque

- Precise alignment for shafts, gearboxes or couplings

- Ease of maintenance and modular installation

When used together with engine plates and motor holders, these components contribute to smooth engine operation and extended system life.

Design and applications

Motor plates and engine holders are used in marine engines, stationary power units, compressors and industrial drives. Depending on engine size and layout, plates may be solid, adjustable or vibration-isolated. Motor flanges are commonly integrated into the plate assembly to allow connection to gearboxes or driven elements.

Material selection – typically steel or aluminum – depends on load class, corrosion resistance and installation environment. In marine applications, coatings or stainless versions of motor plates and engine plates are often used to withstand humidity and salt exposure.

Availability and compatibility

We supply a wide range of motor plates and related mounting components for MTU, MAN, Deutz, Volvo Penta and MWM engines. All parts are OEM-compatible, designed for industrial and marine standards, and available for fast delivery. Our product portfolio covers everything from small motor holders to heavy-duty base plates and motor flanges for high-torque applications.

FAQ

What are motor plates used for?

Motor plates are used to securely mount engines or electric motors to a frame or base. They ensure proper alignment, reduce vibration, and allow safe integration with surrounding components like gearboxes or pumps.

What is the difference between motor holders and motor plates?

Motor holders typically refer to brackets or frames that support and fix the engine in place, while motor plates are flat structural components used for mounting and alignment. In most applications, both are used together.

Are motor flanges part of the plate system?

Yes, motor flanges are often integrated into or mounted on motor plates to connect the engine to a gearbox, pump or shaft. They allow for precise coupling and torque transmission.