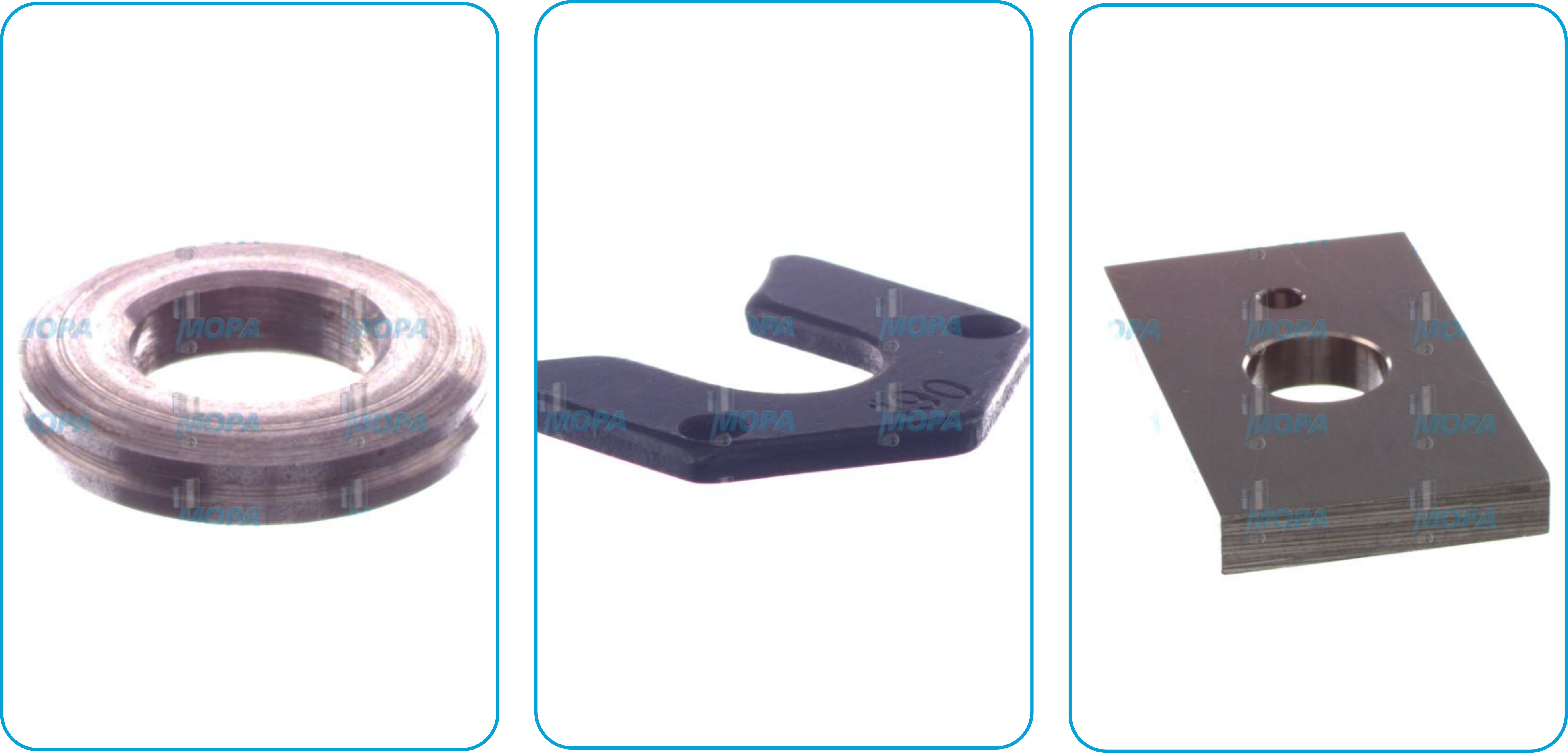

Engine washer – sealing and load distribution for engines

An engine washer is a small yet critical component used in engine assembly to distribute pressure, prevent loosening, and ensure tight seals between fastened surfaces. Whether used under bolts, nuts or screws, the right engine washer supports structural integrity and protects sensitive engine parts. In both marine and industrial engines, high-quality engine washers are essential for reliability and long-term performance.

Function and advantages

Engine washers serve several key functions in engine construction and repair. They are used to:

- Distribute clamping force evenly across surfaces

- Protect soft materials or coatings from fastener damage

- Improve sealing and prevent loosening due to vibration

In dynamic applications, engine washers also help compensate for thermal expansion, surface irregularities and pressure shifts within the engine block or housing.

Types and applications

Engine washers are used across all major engine components – from cylinder heads and manifolds to oil pans, pumps and brackets. Common types include:

- Flat washers for load distribution

- Spring washers for vibration resistance

- Sealing washers (e.g. copper or rubberized) for fluid-tight joints

Each engine washer must be matched to the specific fastener size, torque requirement and environmental condition. In marine and high-vibration engines, corrosion-resistant and locking washer types are preferred.

Materials and availability

Engine washers are typically made from hardened steel, stainless steel, brass, aluminum or copper – depending on application and environment. Coated variants help prevent corrosion and galling. We offer a wide range of engine washers for MTU, MAN, Volvo Penta, Deutz and MWM engines – in OEM-compatible quality and with fast availability.

FAQ

What is an engine washer used for?

An engine washer is placed under a nut, bolt or screw to distribute pressure, improve grip and prevent damage to surrounding surfaces. It also helps maintain torque and sealing under heat, pressure and vibration.

Are all engine washers the same?

No. Engine washers vary in size, thickness, material and function. Some are designed for sealing, others for locking or vibration damping. Using the correct washer type is critical for safety and performance.

When should engine washers be replaced?

Engine washers should be replaced during engine overhauls, when fasteners are removed, or when there are signs of wear, corrosion or deformation. Reusing worn washers can lead to leaks or torque loss.