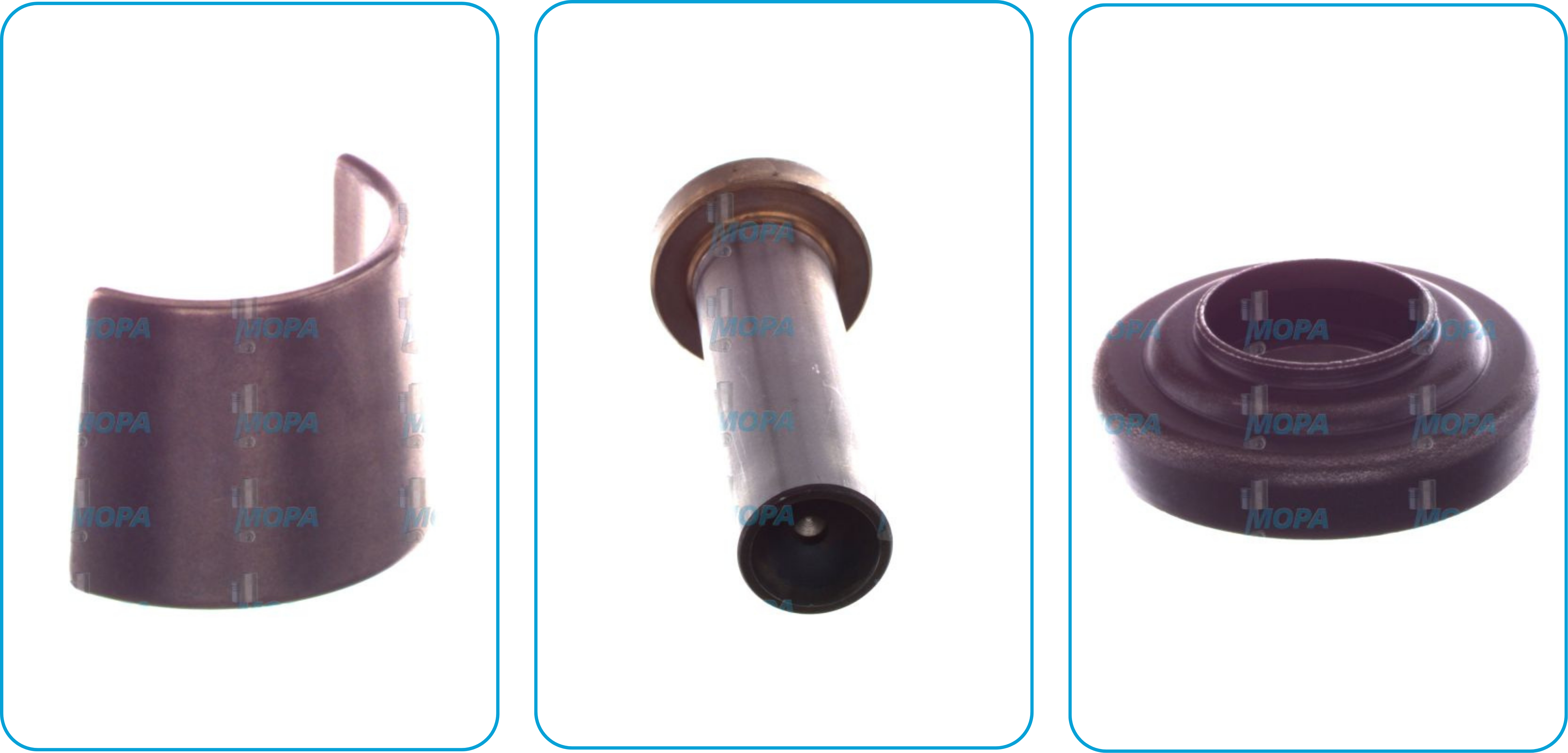

Valve train components – precision control for engine timing

Valve train components are essential for the proper operation of internal combustion engines. They control the opening and closing of intake and exhaust valves, ensuring precise timing and airflow within the combustion chamber. High-quality valve train components are critical to engine performance, efficiency and longevity – especially in high-load industrial and marine engines.

Choose from following:

Function and benefits

The valve train transfers motion from the camshaft to the valves. It includes parts like pushrods, lifters, rocker arms, valve springs and guides. These engine valve components must work in perfect synchronization to ensure proper engine breathing. Key benefits of optimized valve train parts include:

- Precise valve timing and improved combustion efficiency

- Reduced wear and friction under high RPM or load

- Stable performance and lower emissions

Especially in diesel engines, valve train stability is crucial for handling high compression ratios and extended operating cycles.

Applications and system design

Valve train components vary based on engine type (OHV, OHC, DOHC) and application. In marine and industrial engines, components are often designed for durability, corrosion resistance and easy maintenance. Cam profiles, valve clearances and spring tension all influence system behavior and must be matched precisely to the engine’s operating profile.

We supply high-performance engine valve components suitable for MTU, MAN, Deutz, MWM and Volvo Penta engines – with OEM-quality and materials for long service life in harsh operating environments.

Maintenance and replacement

Valve train parts are subject to mechanical wear, thermal expansion and fatigue. Over time, lifters may stick, springs may weaken, and rocker arms may develop play. Regular inspection and preventive replacement of valve train parts helps maintain engine performance and avoid costly failures.

FAQ

What is a valve train?

A valve train is the system of components that controls the opening and closing of an engine’s intake and exhaust valves. It includes the camshaft, lifters, pushrods, rocker arms, valve springs and related parts. The valve train ensures that air and fuel enter and exit the combustion chamber at the right time.

When should valve train components be replaced?

Valve train components should be checked during major engine overhauls or if there are symptoms such as ticking noises, poor compression, rough idling, or loss of power. Worn parts can lead to timing issues, valve damage or engine failure.

Are valve train parts the same for all engines?

No. Valve train designs vary based on engine architecture (e.g., overhead cam vs. pushrod), operating speed, and intended application. Industrial and marine engines often use more robust materials and heavier-duty valve train components to withstand continuous use.