Engine drive components – power transmission for marine and industrial engines

Engine drive components are crucial for transferring mechanical power from the engine to auxiliary systems or the drivetrain. In marine and industrial settings, high-quality engine drive components ensure smooth, efficient and durable performance under high loads and harsh conditions. These parts are central to reliable operation, whether in propulsion systems or stationary generator sets.

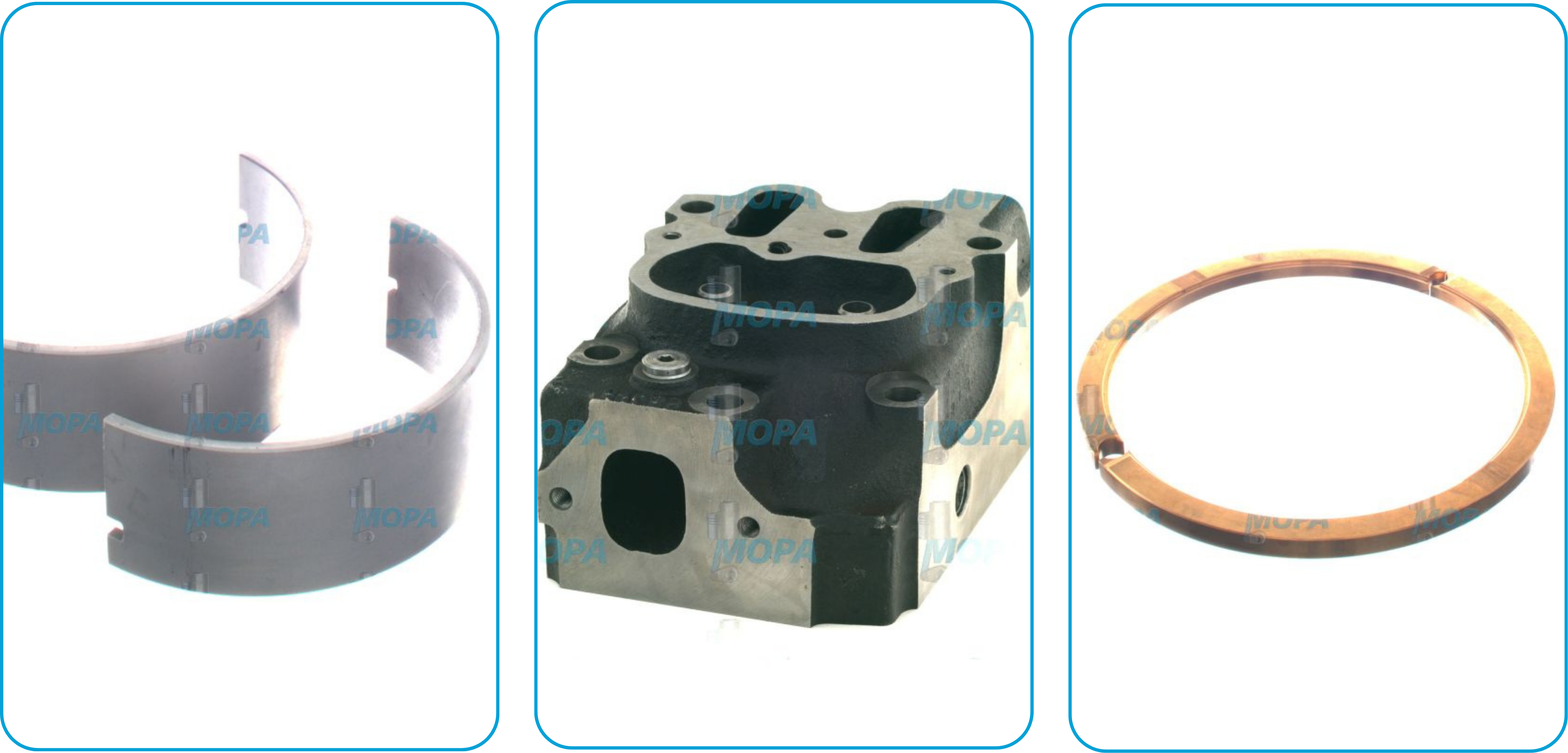

Choose from following:

Function and importance

Engine drive components connect rotating elements, absorb torque, and allow controlled movement between engine and peripheral units. They include couplings, pulleys, belts, shafts and dampers – each designed to handle vibration, misalignment and thermal expansion. Key advantages include:

- Efficient transmission of rotational energy

- Protection of connected equipment from overload or vibration

- Long service life under constant use

In marine engines, components must resist corrosion, temperature changes and dynamic load cycles over long operational periods.

Applications and system integration

Engine drive components are used in propulsion systems, pumps, generators, alternators, and compressors. Depending on the engine configuration, they may be rigid, flexible, torsionally elastic, or damped. These components must be matched precisely to engine speed, torque curve and mounting conditions.

Our product range includes drive components compatible with MTU, MAN, Volvo Penta, MWM and Deutz engines – suitable for shipbuilding, power generation and heavy machinery.

Materials and reliability

Depending on the design, engine drive components are made from alloy steel, elastomers, composites or specialized castings. Material choice depends on load, vibration, heat exposure and environmental conditions. Proper selection prevents premature wear, power loss or failure under stress.

FAQ

What are engine drive components?

Engine drive components are mechanical parts that transmit power from an engine to auxiliary units or propulsion systems. They include couplings, shafts, dampers, belts and pulleys, ensuring safe and efficient torque transfer.

When should drive components be replaced?

Drive components should be checked regularly for wear, cracking, misalignment or unusual noise. Replacement is recommended during overhauls or when vibration, power loss or damage is detected in the drivetrain.

Are marine engine drive components different from standard ones?

Yes. Marine components must resist corrosion, salt exposure and constant vibration. They often feature coated surfaces, sealed housings or reinforced elastomers to ensure reliable operation in demanding marine environments.